Light-emitting diode having heat conducting layer and preparation method thereof

A technology of light-emitting diodes and heat-conducting layers, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of reduced, increased, and inconspicuous lifespan, and achieve the reduction of excessive local temperature, reduced service life, and reduced warpage The effect of curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

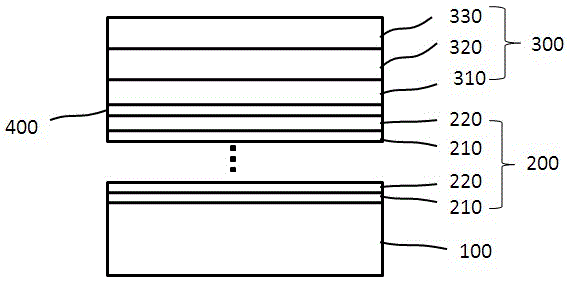

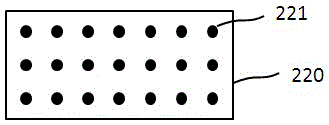

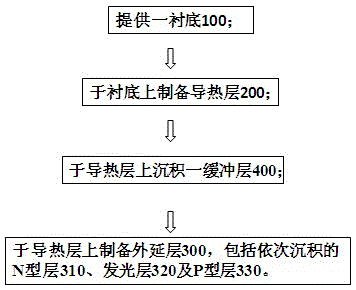

[0030] See attached figure 1 The present invention proposes a light-emitting diode with a heat-conducting layer 200, which at least includes: a substrate 100 and an epitaxial layer 300 composed of an N-type layer 310, a light-emitting layer 320, and a P-type layer 330 sequentially located on the substrate 100, the The light emitting diode further includes a heat conduction layer 200 inserted between the substrate 100 and the N-type layer 310 , and further includes a buffer layer 400 between the heat conduction layer 200 and the N-type layer 310 . Wherein, the substrate 100 is a sapphire substrate or a silicon carbide substrate or a silicon substrate. The N-type layer 310 includes a high-temperature GaN buffer layer and an n-GaN layer (not shown in the fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com