Integrated whole-powder production method for potatoes and other root and tuber crops

A production method and tuber technology are applied in the field of whole flour integrated production of potatoes and other root and tuber crops, which can solve the problems of low income, backward processing methods and high processing costs, and achieve no nutrient loss, wide application, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

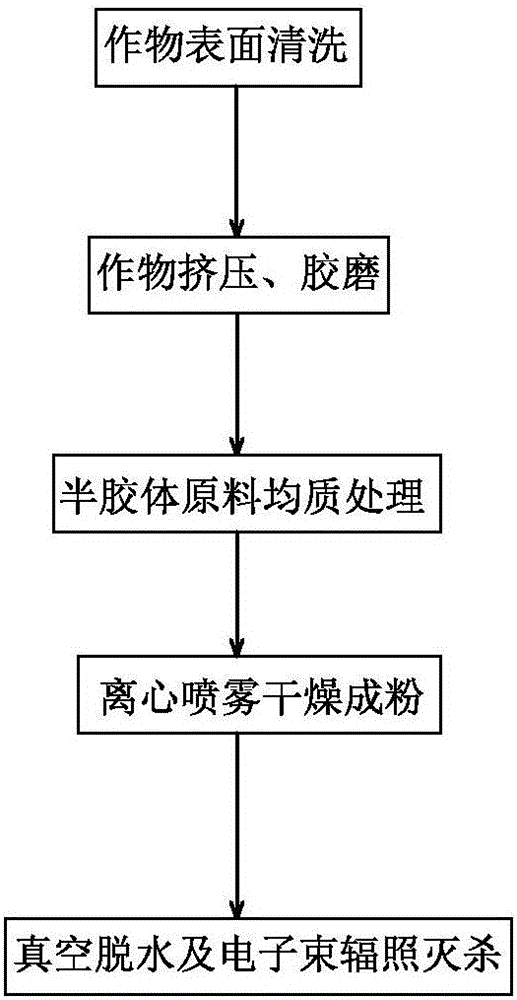

[0016] refer to figure 1 , the present invention will be described in detail below with specific embodiments, and the method of the present invention is used to process the potato of a certain variety:

[0017] a. Crop surface cleaning: First, a tilting, shaking and rolling cone and cylinder body is used as the main container, and a stepless frequency conversion automatic control method is used to remove the epidermis and dust impurities with hard quartz sand, and water is used as the solid-liquid The mixture is used to purify the surface of the potato in one step, and then the potato mixed with dust, skin and quartz sand is placed under the pressurized spray device by using a sliding stainless steel mesh, and the stainless steel mesh is continuously shaken to continuously spray clean water. to completely purify the potatoes;

[0018] b. Crop extrusion and rubber grinding: the clean potatoes are sent into a concave-convex powerful crusher to be squeezed into a mixed shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com