Preparation method for alvimopan capsule

A capsule, polyethylene glycol technology, applied in the directions of capsule delivery, digestive system, active ingredients of heterocyclic compounds, etc., can solve problems such as poor content uniformity, and achieve suitable for large-scale industrial production, good dissolution gradient, and excellent uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

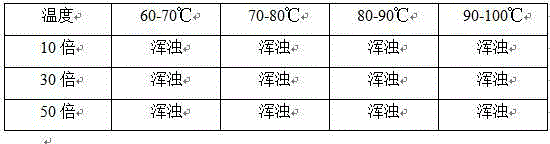

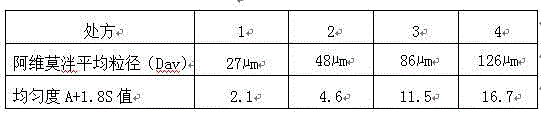

Method used

Image

Examples

Embodiment 1

[0074] prescription:

[0075] Avimopan 12g main medicine

[0076] Monoethanolamine 6g cosolvent

[0077] Polyethylene glycol (3350) 600g dispersion medium

[0078]

[0079] 618g

[0080] Process: Melt polyethylene glycol, lower the temperature to about 70±2℃, add 12g of monoethanolamine, then add the prescription amount of aviemopan raw materials, stir evenly and clarify, reduce the temperature to about 60℃, and fill it into hard Gelatin capsules.

Embodiment 2

[0082] prescription:

[0083] Avimopan 12g main medicine

[0084] Monoethanolamine 24g cosolvent

[0085] Polyethylene glycol (4000) 480g dispersion medium

[0086]

[0087] 516g

[0088] Process: Melt polyethylene glycol, lower the temperature to about 70±2°C, add monoethanolamine, then add the prescription amount of aviemopan raw materials, stir until it is clear, and lower the temperature to about 60°C, then add hard gelatin capsule.

Embodiment 3

[0090] prescription:

[0091] Avimopan 6g main medicine

[0092] Triethanolamine 30g cosolvent

[0093] Polyethylene glycol (6000) 420g dispersion medium

[0094]

[0095] 456g

[0096] Process: Melt polyethylene glycol, lower the temperature to about 70±2°C, add triethanolamine, then add the prescription amount of aviemopan raw material, stir until it is clear, and lower the temperature to about 60°C, then add hard gelatin capsule.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com