Carbon fiber composite plate

A composite board and carbon fiber technology, applied in the field of carbon fiber, can solve the problems of weight and corrosion resistance, and achieve the effect of widely popularizing, eliminating fatigue, and improving the body's immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

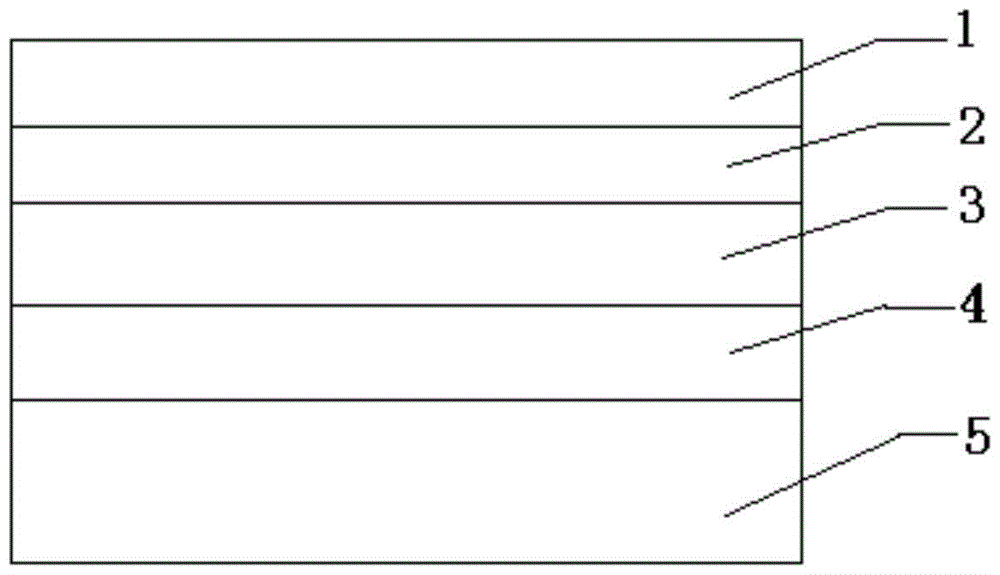

[0010] A carbon fiber composite board, comprising a carbon fiber layer, a reinforcement layer, a fireproof layer and a waterproof layer, characterized in that the upper and lower layers of the carbon fiber layer 3 are provided with reinforcement layers, the upper surface of the upper reinforcement layer 2 is a fireproof layer 1, and the lower reinforcement layer 4 The lower surface is a waterproof layer 5, and the layers are bonded together with an adhesive.

[0011] The carbon fiber layer 3 is made of graphite material obtained by carbonizing and graphitizing organic fibers, and its carbon content is above 80%.

[0012] The material of the upper reinforcement layer 2 is epoxy resin, the material of the lower reinforcement layer 4 is silicon dioxide, the material of the fireproof layer 1 is aluminum hydroxide with aluminum powder coated on the surface, and the material of the waterproof layer 5 is silica gel.

[0013] The invention provides a carbon fiber composite board, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com