Non-woven fabric winding device

A technology of non-woven fabrics and fabric guides, applied in the field of non-woven fabric collection devices, can solve the problems of mopping and knotting of non-woven fabrics, hidden dangers of product quality, and sometimes loose and tight non-woven fabrics, so as to improve the yield of finished products. , Reduce production costs and ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

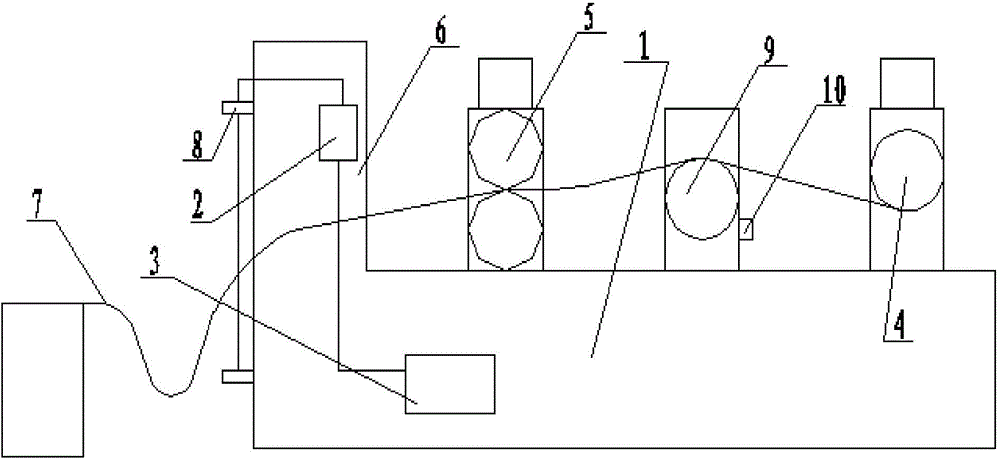

[0015] With reference to illustration 1, a non-woven cloth receiving device of the present invention includes a frame 1, a collector 2 arranged on the frame 1, a controller 3 and a motor driven by an adjustable speed motor arranged at the tail end of the frame 1 The front end of the frame 1 is provided with a cloth guide arm 5, and there are two cloth guide arms 5, and the frame 1 is provided with a gantry 6 at the front end of the cloth guide arm 5, without The woven fabric 7 passes through the middle of the gantry frame 6, and is guided on the frame 1 in the middle of the two cloth guide arms 5. The top of the gantry frame 6 is provided with a vertical photoelectric switch 8. The vertical photoelectric switch 8 passes through the collector 2, and then is electrically connected to the adjustable speed motor through the controller 3; the vertical photoelectric switch 8 monitors the vertical distance between the non-woven fabric 7 and the top of the gantry frame 6, and sends the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com