High temperature-resistant and high-insulation sealing glass and preparation method thereof

A technology of sealing glass and high insulation, which is applied in the field of glass preparation, can solve the problems of not being able to meet the production requirements, not being used, not being achieved, etc., and achieve the effects of improving glass fluidity, improving chemical stability, and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing a high-temperature-resistant high-insulation sealing glass, the specific steps are as follows:

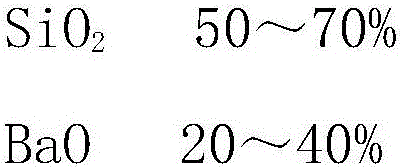

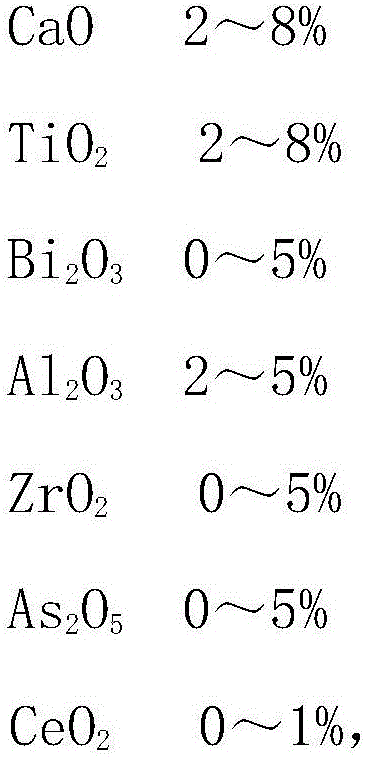

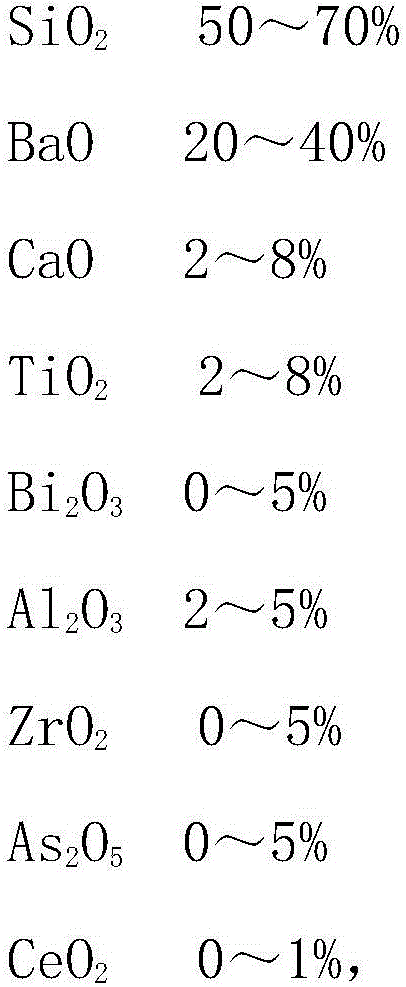

[0023] 1), get the raw material in molar percentage,

[0024]

[0025] 2), uniformly mix the raw materials selected in step 1) to form a batch, and then heat the batch at 200-300°C for 4 hours for pretreatment;

[0026] 3) Put the pretreated batch material into a platinum crucible, and then put the platinum crucible into a silicon-molybdenum high-temperature furnace to melt to obtain a clarified glass liquid. The melting process is as follows: from room temperature to 5-8°C / min Speed up to 1400-1550°C, keep warm at 1400-1550°C for 30min-90min;

[0027] 4) Then pour the melted glass liquid into the mold to prepare samples according to the requirements, and cool naturally to obtain the required sealing glass.

[0028] Wherein, in step 2), the batch material is put into a high-temperature furnace and kept at 200-300° C. for 4 hours for pretreatment...

Embodiment 1

[0034] 1), mix the prepared glass raw materials according to the following mole percentages to form a batch, SiO 2 :BaO:CaO:TiO 2 : Bi 2 o 3 :Al 2 o 3 : ZrO 2 :As 2 o 5 : CeO 2 is 50:30:4:7:2:2:1:3:1,

[0035] 2), uniformly mix the raw materials selected in step 1) into a batch, and then put the batch into a high-temperature furnace and heat it at 200-300°C for 4 hours for pretreatment;

[0036] 3) Put the pretreated batch material into a platinum crucible, and then put the platinum crucible into a silicon-molybdenum high-temperature furnace to melt to obtain a clarified glass liquid. The specific melting process is: heating up from room temperature at a rate of 5-8°C / min to 1434°C, then keep at 1434°C for 60 minutes;

[0037] 4) Then pour the melted glass liquid into the mold to prepare samples according to the requirements, and cool naturally to obtain the required sealing glass.

[0038] Through testing, the obtained high-temperature-resistant and high-insulation...

Embodiment 2

[0041] 1), mix the prepared glass raw materials according to the following mole percentages to form a batch, SiO 2 :BaO:CaO:TiO 2 : Bi 2 o 3 :Al 2 o 3 : ZrO 2 :As 2 o 5 : CeO 2 is 53:27:7:4:3:3:1:2:1,

[0042] 2), uniformly mix the raw materials selected in step 1) into a batch, and then put the batch into a high-temperature furnace and heat it at 200-300°C for 4 hours for pretreatment;

[0043] 3) Put the pretreated batch material into a platinum crucible, and then put the platinum crucible into a silicon-molybdenum high-temperature furnace to melt to obtain a clarified glass liquid. The specific melting process is: heating up from room temperature at a rate of 5-8°C / min To 1464°C, hold at 1464°C for 60min;

[0044] 4) Then pour the melted glass liquid into the mold to prepare samples according to the requirements, and cool naturally to obtain the required sealing glass.

[0045] Through testing, the obtained high-temperature-resistant and high-insulation sealing g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sealing temperature | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Sealing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com