Preparation method of transparent superhydrophilic porous titanium dioxide film for solar thermal power generation mirror

A solar thermal power generation, porous titanium dioxide technology, applied in the direction of coating, etc., can solve the problem of not being retrieved, and achieve the effects of strong and easy cleaning ability, strong impact resistance, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

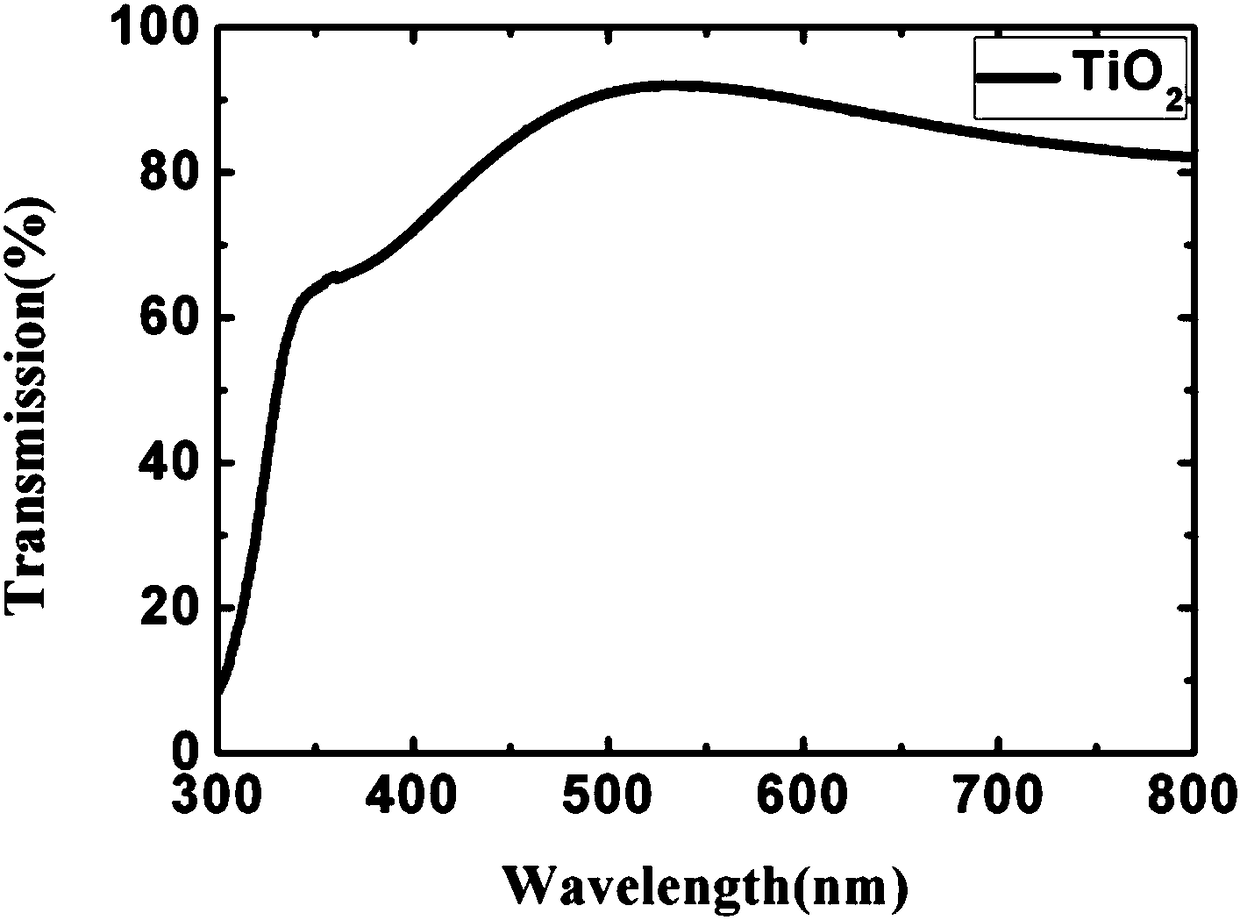

[0029] A method for preparing a transparent superhydrophilic porous titanium dioxide film for a solar thermoelectric mirror, comprising the following steps:

[0030] (1) Clean the glass substrate with washing liquid and deionized water, then ultrasonically clean it with acetone, absolute ethanol, and deionized water for 15 minutes, then wash it again with absolute ethanol, and dry it for later use;

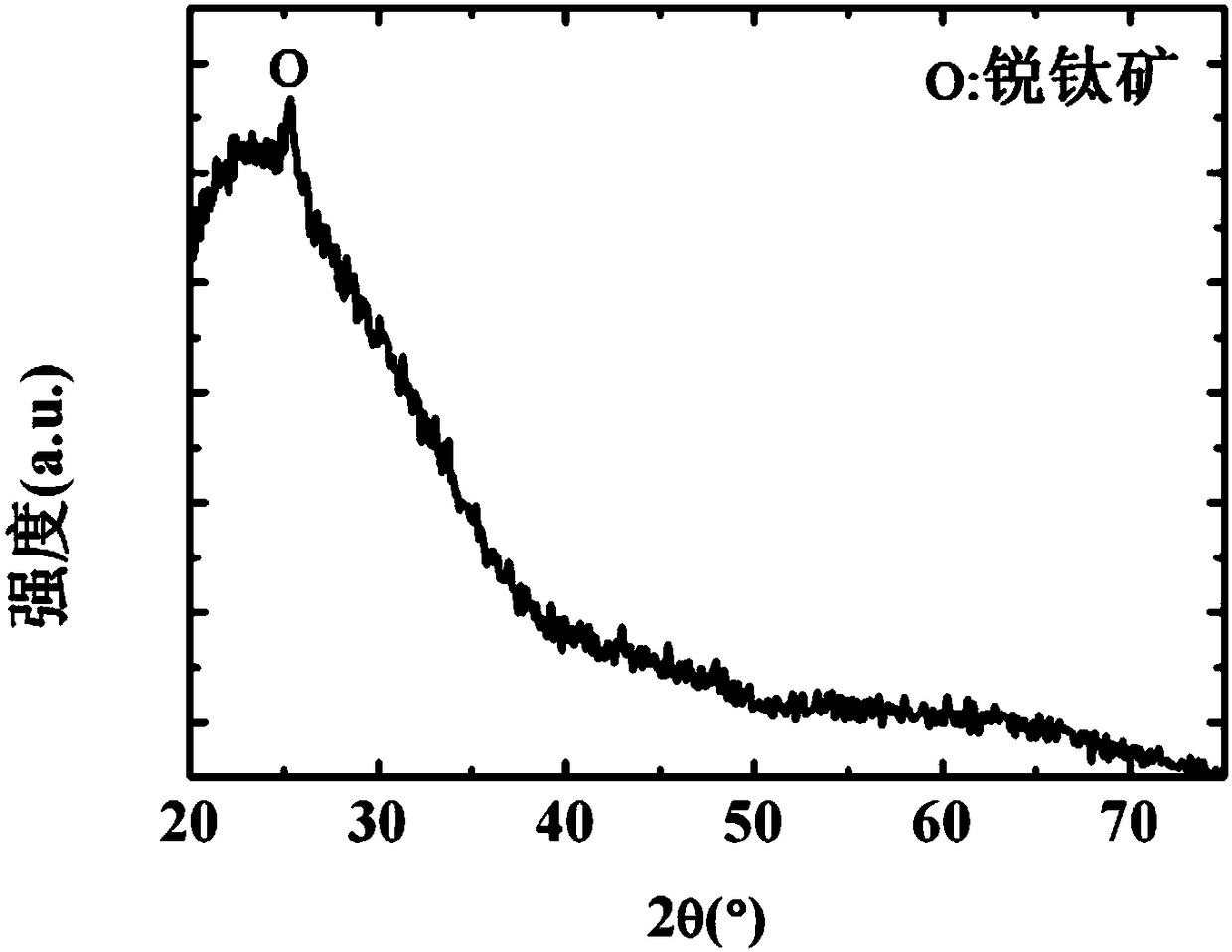

[0031] (2) Accurately measure 60ml of absolute ethanol, 10ml of butyl titanate, 2ml of acetylacetone, 0.7ml of ammonia water and stir at room temperature for 10min to form A solution; then measure 30ml of absolute ethanol, 10ml of deionized water and 1ml of concentrated hydrochloric acid Mix well to form B solution, add B solution dropwise to A solution, continue to stir at 20 °C for 1 h, and form a stable yellow transparent TiO 2 Sol.

[0032] (3) Using the spin coating method, the TiO that has not been aged in step (2) 2 Take 1 drop of sol on the center of the glass substrate ...

Embodiment 2

[0036] A method for preparing a transparent superhydrophilic porous titanium dioxide film for a solar thermoelectric mirror, comprising the following steps:

[0037] (1) Clean the glass substrate with washing liquid and deionized water, then ultrasonically clean it with acetone, absolute ethanol, and deionized water for 30 minutes respectively, then wash it with absolute ethanol again, and dry it for later use;

[0038] (2) Accurately measure 120ml of absolute ethanol, 10ml of butyl titanate, 2ml of acetylacetone, 0.7ml of ammonia water and stir for 30min at 25°C to form A solution; then measure 60ml of absolute ethanol, 10ml of deionized water and 1ml of concentrated Mix hydrochloric acid evenly to form B solution, add B solution to A solution drop by drop, continue to stir at 40°C for 2 hours, seal and darken for 24 hours, and form stable yellow transparent TiO 2 Sol.

[0039] (3) adopt spin-coating method, in step (2) TiO 2 Take 1 drop of the sol and drop it on the center...

Embodiment 3

[0048] A method for preparing a transparent superhydrophilic porous titanium dioxide film for a solar thermoelectric mirror, comprising the following steps:

[0049] (1) Clean the glass substrate with washing liquid and deionized water, then ultrasonically clean it with acetone, absolute ethanol, and deionized water for 20 minutes respectively, then wash it with absolute ethanol once, and dry it for later use;

[0050] (2) Accurately measure 180ml of absolute ethanol, 10ml of butyl titanate, 2ml of acetylacetone, 0.7ml of ammonia water and stir at 25°C for 60min to form A solution; then measure 90ml of absolute ethanol, 10ml of deionized water and 1ml of concentrated Mix hydrochloric acid evenly to form B solution, add B solution drop by drop to A solution, continue to stir at 60°C for 4 hours, seal and darken for 24 hours, and form stable yellow transparent TiO 2 Sol.

[0051] (3) adopt spin-coating method, in step (2) TiO 2 Take 1 drop of sol and drop it on the center of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

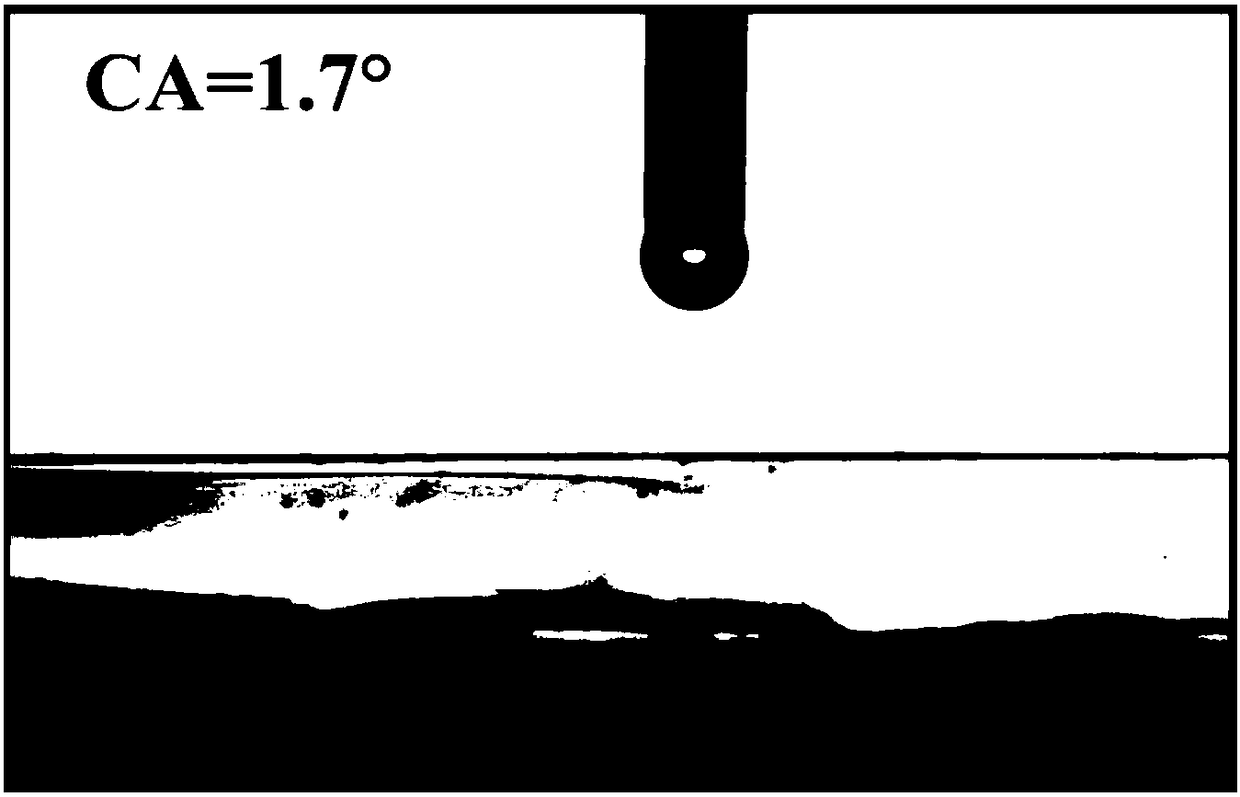

| water contact angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com