Aventurine metallic luster glaze and preparation method thereof

A technique for metallic luster and Venus glaze, applied in the field of Venus metallic luster glaze and its preparation, can solve the problems of unstable firing effect of the firing process, and achieve the effects of moderate size of Venus, few pinholes on the glaze surface and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

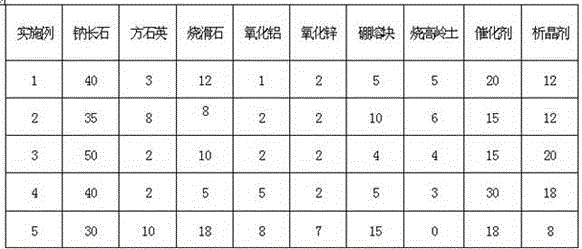

[0026] A kind of Venus metallic luster glaze, raw material is composed in Table 1 by weight, SiO in the cristobalite 2 The content is 99.5%.

[0027] The catalyst is a P-Al-based mixture, and its chemical composition is as follows in terms of mass percentage: loss on ignition: 18.5%, SiO 2 : 5.5%, Al 2 o 3 : 18%, P 2 o 5 : 51%, Na 2 O: 1.0%, ZnO: 5.5%, does not contain lead and chromium elements, and the balance is other unavoidable impurity elements; the crystallization agent is a P-Fe system mixture, and its chemical composition is as follows in terms of mass percentage: loss on ignition : 22.2%, Fe 2 o 3 : 40.5%, P 2 o 5 : 37%, without lead and chromium, and the balance is other unavoidable impurity elements.

[0028] The production and application method of Jinxing metallic luster glaze, the specific steps are as follows:

[0029] 1) Prepare glaze slurry

[0030] The raw materials are mixed evenly according to the proportion to obtain the total dry material, an...

Embodiment 2

[0036] A kind of Venus metallic luster glaze, raw material is composed in Table 1 by weight, SiO in the cristobalite 2 The content is 99.5%.

[0037] The catalyst is a P-Al-based mixture, and its chemical composition is as follows in terms of mass percentage: loss on ignition: 18.5%, SiO 2 : 5.5%, Al 2 o 3 : 18%, P 2 o 5 : 51%, Na 2 O: 1.0%, ZnO: 5.5%, does not contain lead and chromium elements, and the balance is other unavoidable impurity elements; the crystallization agent is a P-Fe system mixture, and its chemical composition is as follows in terms of mass percentage: loss on ignition : 22.2%, Fe 2 o 3 : 40.5%, P 2 o 5 : 37%, without lead and chromium, and the balance is other unavoidable impurity elements.

[0038] The production and application method of Jinxing metallic luster glaze, the specific steps are as follows:

[0039] 1) Prepare glaze slurry

[0040] The raw materials are mixed evenly according to the proportion to obtain the total dry material, an...

Embodiment 3

[0046] A kind of Venus metallic luster glaze, raw material is composed in Table 1 by weight, SiO in the cristobalite 2 The content is 99.5%.

[0047] The catalyst is a P-Al-based mixture, and its chemical composition is as follows in terms of mass percentage: loss on ignition: 18.5%, SiO 2 : 5.5%, Al 2 o 3 : 18%, P 2 o 5 : 51%, Na 2 O: 1.0%, ZnO: 5.5%, does not contain lead and chromium elements, and the balance is other unavoidable impurity elements; the crystallization agent is a P-Fe system mixture, and its chemical composition is as follows in terms of mass percentage: loss on ignition : 22.2%, Fe 2 o 3 : 40.5%, P 2 o 5 : 37%, without lead and chromium, and the balance is other unavoidable impurity elements.

[0048] The production and application method of Jinxing metallic luster glaze, the specific steps are as follows:

[0049] 1) Prepare glaze slurry

[0050] The raw materials are mixed evenly according to the proportion to obtain the total dry material, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com