On-site processing method for summer vegetable leaf and vegetable waste

A treatment method and waste technology, applied in the direction of microbial treatment, fertilizer mixture, application, etc., can solve the problems of increased treatment links, high treatment costs, and difficulty in turning piles, so as to alleviate labor tension, simple workflow, and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

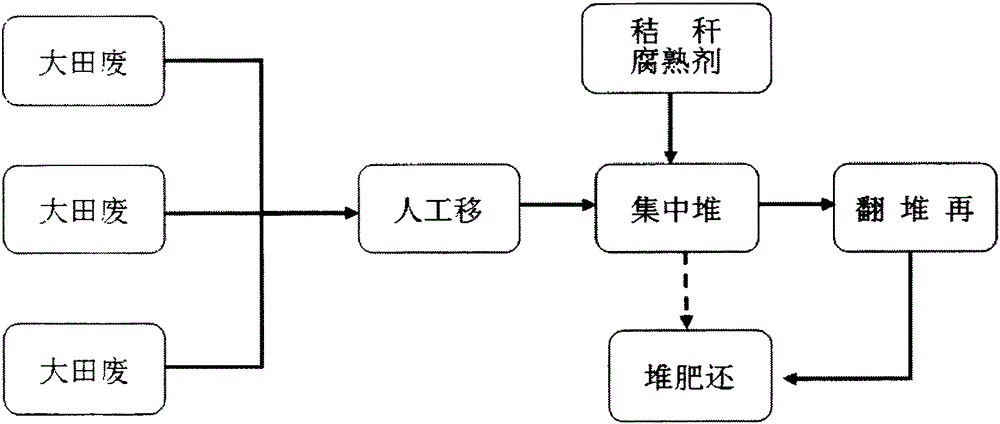

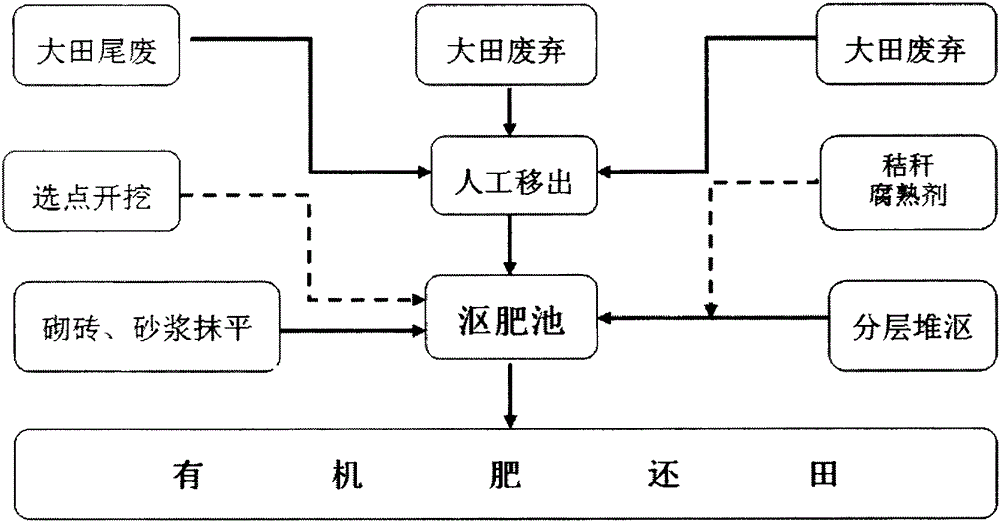

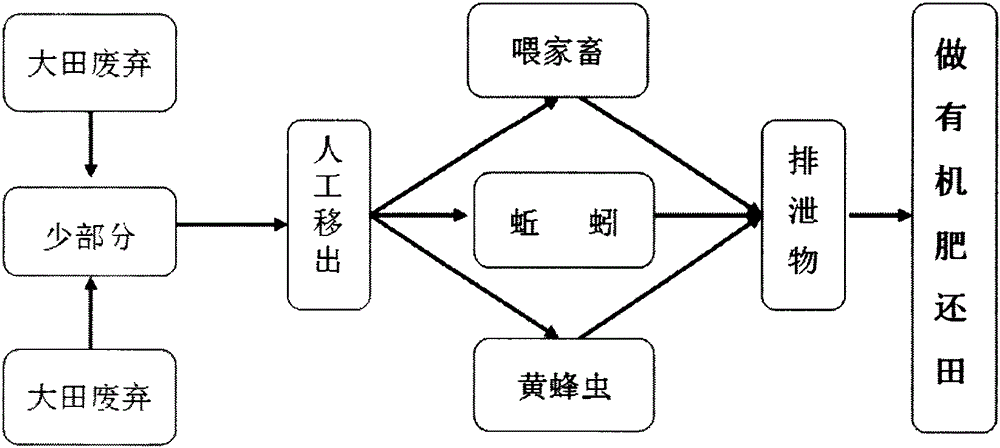

[0025] Below in conjunction with accompanying drawing, the present invention will be further described.

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

[0027] Such as Figure 5 Shown, this embodiment adopts following technical scheme: its processing method is:

[0028] 1. In areas where there are two consecutive crops, the harvest period of the first crop coincides with the high temperature and rainy season. After the commercial vegetables are harvested, the waste is kept in the field without any movement, and left to the wind and sun on the planting ridge. And rain, play a role in protecting the mulch. After a wee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com