Stable vildagliptin compound

A compound and composition technology, applied in the field of medicine, can solve the problems of high total amount of impurities, large number of vildagliptin impurities, difficult to repeat the crystal form, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

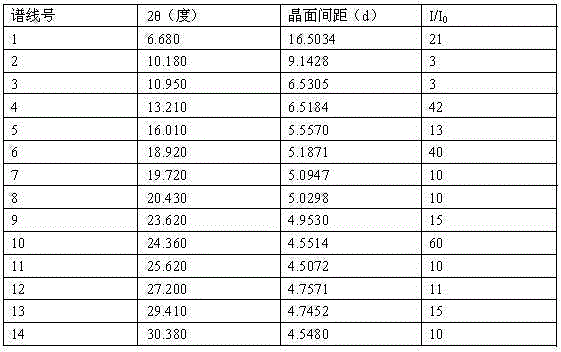

Image

Examples

Embodiment 1

[0035] In a 100L reaction kettle, add 6 kg of vildagliptin (purity 98.06%, HPLC) and 36L of acetone-acetonitrile-ammonia water = 3:1:0.5 mixture, heat to 60°C, keep warm for 30 minutes, while hot filter. The filtrate was kept at 30°C for 1.5 hours; then naturally cooled to room temperature and kept for 2.5 hours, the precipitated crystals were filtered and dried naturally at room temperature to obtain 5.71 kg of white crystals with a purity of 99.91%, and the solvent residue test met the requirements.

Embodiment 2

[0037] In a 100L reaction kettle, add 6 kg of vildagliptin (purity 98.06%, HPLC) and 48L of acetone-acetonitrile-ammonia = 3:2:1 mixture, heat to 70°C, keep warm for 30 minutes, while hot filter. The filtrate was kept at 35°C for 1 hour; then naturally cooled to room temperature and kept for 2 hours, the precipitated crystals were filtered and dried naturally at room temperature to obtain 5.56 kg of white crystals with a purity of 99.92%, and the solvent residue test met the requirements.

[0038] Microparticles or microspheres are prepared by combining the compounds of the present invention with a pharmaceutically acceptable solid or liquid carrier, and optionally with pharmaceutically acceptable adjuvants and vehicles, using standard and conventional techniques. The composition is used for the preparation of oral preparations. It is given by way of example only and in no way is it intended to limit the scope of the invention in any way.

Embodiment 3

[0040] Tablets containing vildagliptin

[0041] Prescription: 20 grams of vildagliptin, 10 grams of N-methylglucosamine, 21 grams of polyvinylpyrrolidone, 200 grams of microcrystalline cellulose, 150 grams of sodium carboxymethyl starch, 15 grams of magnesium stearate, appropriate amount of distilled water, Made in 10000 pieces.

[0042] Process: Dissolve vildagliptin and excipients in distilled water at 80°C, add 5% of microcrystalline cellulose, mix well, dry in vacuum, pulverize, pass through a 100-mesh sieve, mix well with other materials and press piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com