A kind of addition type liquid fluorosilicone rubber base glue and preparation method thereof

A technology of liquid fluorosilicone and base rubber, which is applied in the field of addition-type liquid fluorosilicone rubber base rubber and its preparation. It can solve problems such as affecting vinyl crosslinking activity, product turbidity, and damage to the oil resistance of fluorosilicone rubber, and achieve space reduction. Effect of steric hindrance, guarantee of cross-linking activity, effect of reducing shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

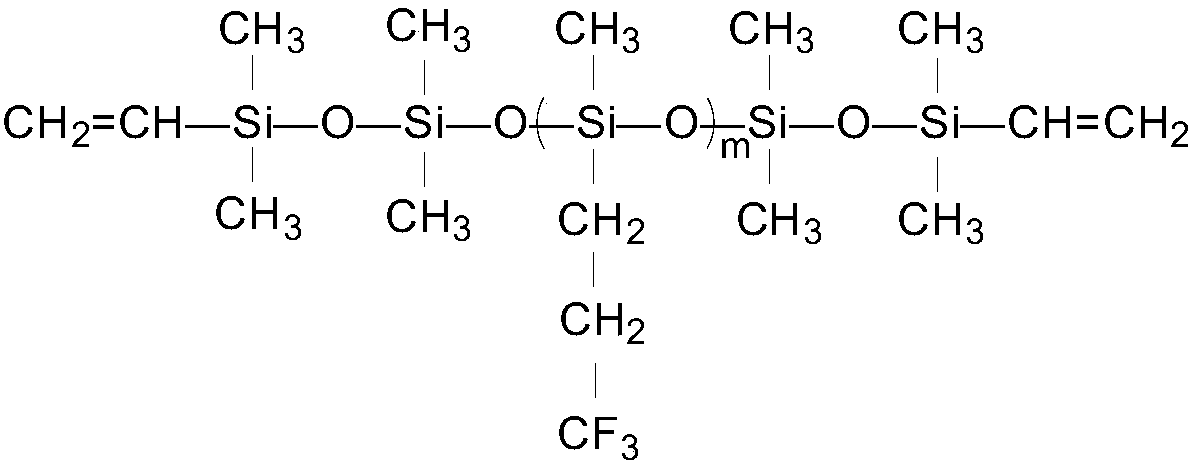

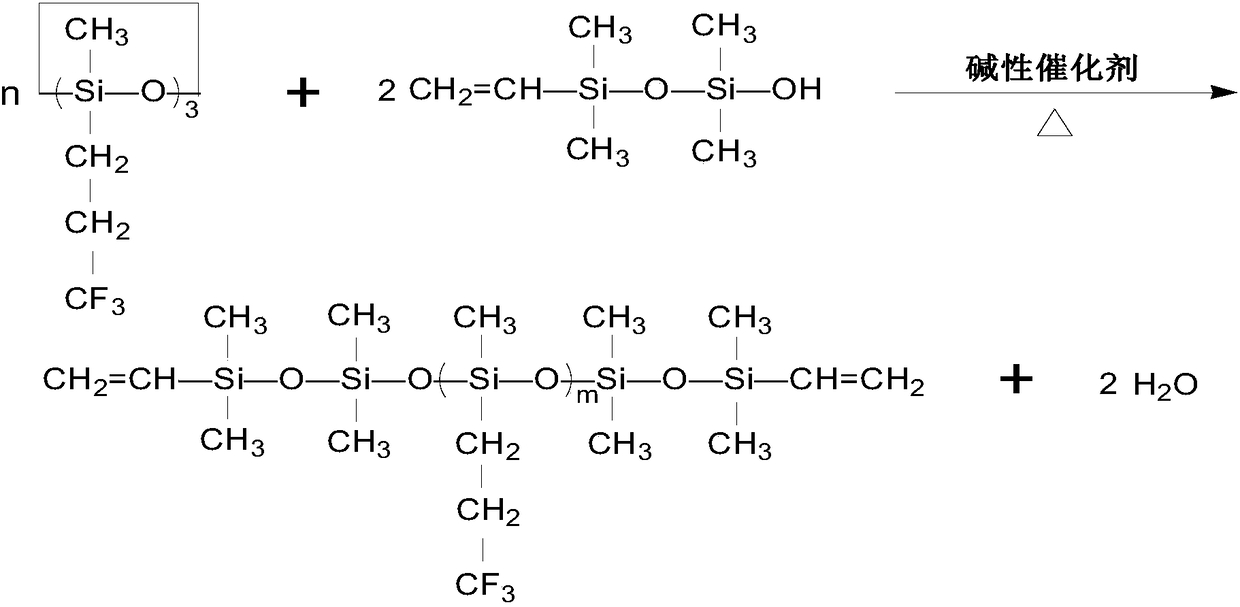

[0039] An addition-type liquid fluorosilicone rubber base rubber has the following structural formula:

[0040] Vi(Me) 2 SiO-Si(Me) 2 O-[Si(Rf)(Me)O] 35 -Si(Me) 2 O-Si(Me) 2 Vi

[0041] The preparation steps are as follows:

[0042] (1) Add 600g trifluoropropylmethylcyclotrisiloxane (D 3 F), 37.5g 1-vinyl-3-hydroxyl-1,1,3,3-tetramethyldisiloxane (purity 96%) and 0.5g sodium hydroxide silicon alkoxide (NaOH content 4.05%), stirring Uniform;

[0043] (2) At room temperature, evacuate the reactor to -0.04MPa, turn on the heating, raise the temperature to 120-130°C to initiate the reaction of the system and maintain it for 2.5h, maintain the pressure of -0.04MPa to -0.08MPa throughout the reaction, and the water vapor generated by the polymerization, As the reaction proceeds, it is continuously sucked away by negative pressure;

[0044](3) After the reaction is complete, add silicon-based phosphate to neutralize the catalyst and keep it for 0.5h;

[0045] (4) Under the p...

Embodiment 2

[0048] An addition-type liquid fluorosilicone rubber base rubber has the following structural formula:

[0049] Vi(Me) 2 SiO-Si(Me) 2 O-[Si(Rf)(Me)O] 68 -Si(Me) 2 O-Si(Me) 2 Vi

[0050] The preparation steps are as follows:

[0051] (1) Add 600g trifluoropropylmethylcyclotrisiloxane (D 3 F), 20g 1-vinyl-3-hydroxyl-1,1,3,3-tetramethyldisiloxane (purity 96%) and 0.48g sodium hydroxide silicon alkoxide (NaOH content 4.05%), stir well ;

[0052] (2) At room temperature, vacuumize the reactor to -0.04MPa, turn on the heating, raise the temperature to 120-130°C to initiate the reaction of the system and maintain it for 2.5h, maintain the pressure of -0.04MPa to -0.08MPa throughout the reaction, and the water vapor generated by the polymerization, As the reaction proceeds, it is continuously sucked away by negative pressure;

[0053] (3) After the reaction is complete, add silicon-based phosphate to neutralize the catalyst and keep it for 0.5h;

[0054] (4) Under the pressu...

Embodiment 3

[0057] An addition-type liquid fluorosilicone rubber base rubber has the following structural formula:

[0058] Vi(Me) 2 SiO-Si(Me) 2 O-[Si(Rf)(Me)O] 170 -Si(Me) 2 O-Si(Me) 2 Vi

[0059] The preparation steps are as follows:

[0060] (1) Add 600g trifluoropropylmethylcyclotrisiloxane (D 3 F), 9g 1-vinyl-3-hydroxyl-1,1,3,3-tetramethyldisiloxane (purity 96%) and 0.49g sodium hydroxide silicon alkoxide (NaOH content 4.05%), stir well ;

[0061] (2) At room temperature, vacuumize the reactor to -0.04MPa, turn on the heating, raise the temperature to 120-130°C to initiate the reaction of the system and maintain it for 2.5h, maintain the pressure of -0.04MPa to -0.08MPa throughout the reaction, and the water vapor generated by the polymerization, As the reaction proceeds, it is continuously sucked away by negative pressure;

[0062] (3) After the reaction is complete, add silicon-based phosphate to neutralize the catalyst and keep it for 0.5h;

[0063] (4) Under the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com