Membrane material for vacuum compressed bag and preparation method thereof

A technology for vacuum compression bags and film materials, applied in the field of packaging materials, can solve the problems of aging and rupture of vacuum compression bags, insufficient mechanical strength and hardening, and achieve the effects of good weather resistance, excellent flexibility and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

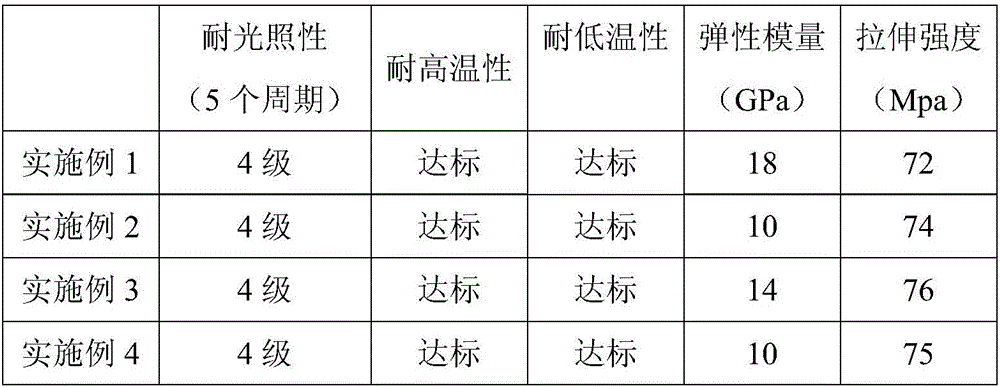

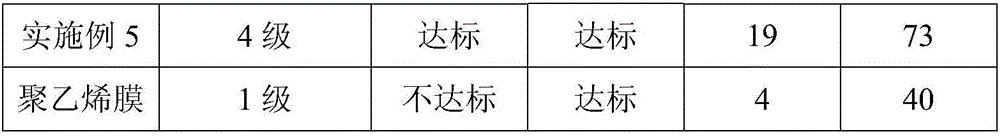

Examples

Embodiment 1

[0019] A film material for a vacuum compression bag, comprising the following components in parts by weight: 15 parts of polyethylene, 4 parts of 2,2-dimethylol propionic acid, 20 parts of polyethylene terephthalate, formaldehyde 9 parts of trichlorosilane, 4 parts of acrylonitrile, 3 parts of butadiene, 10 parts of styrene, 3 parts of diphenyldichlorosilane, 1 part of monoalkoxy pyrophosphate, 1.2 parts of dicumyl peroxide .

[0020] Preparation:

[0021] (1) by weight, each component is weighed;

[0022] (2) Put each component into a high-speed mixer and mix evenly;

[0023] (3) The raw materials mixed in step (2) are extruded at high temperature with a twin-screw extruder. During twin-screw extrusion, the length-to-diameter ratio of the screw is 25:1, and the extrusion temperature of the twin-screw extruder is: the first zone The temperature is 172°C, the temperature in the second zone is 180°C, the temperature in the third zone is 200°C, and the temperature in the fourt...

Embodiment 2

[0026] A film material for a vacuum compression bag, comprising the following components in parts by weight: 17 parts of polyethylene, 5 parts of 2,2-dimethylolpropionic acid, 22 parts of polyethylene terephthalate, formaldehyde 9 parts of trichlorosilane, 4 parts of acrylonitrile, 3 parts of butadiene, 11 parts of styrene, 3 parts of diphenyldichlorosilane, 1.2 parts of monoalkoxy pyrophosphate, 1.3 parts of dicumyl peroxide .

[0027] Preparation:

[0028] (1) by weight, each component is weighed;

[0029] (2) Put each component into a high-speed mixer and mix evenly;

[0030] (3) The raw materials mixed in step (2) are extruded at high temperature with a twin-screw extruder. During twin-screw extrusion, the length-to-diameter ratio of the screw is 28:1, and the extrusion temperature of the twin-screw extruder is: the first zone The temperature is 172°C, the temperature in the second zone is 183°C, the temperature in the third zone is 202°C, and the temperature in the fou...

Embodiment 3

[0033] A film material for a vacuum compression bag, comprising the following components in parts by weight: 18 parts of polyethylene, 5 parts of 2,2-dimethylolpropionic acid, 23 parts of polyethylene terephthalate, formaldehyde 10 parts of trichlorosilane, 4 parts of acrylonitrile, 4 parts of butadiene, 11 parts of styrene, 3 parts of diphenyldichlorosilane, 1.3 parts of monoalkoxy pyrophosphate, 1.3 parts of dicumyl peroxide .

[0034] Preparation:

[0035] (1) by weight, each component is weighed;

[0036] (2) Put each component into a high-speed mixer and mix evenly;

[0037] (3) The raw materials mixed in step (2) are extruded at high temperature by a twin-screw extruder. During twin-screw extrusion, the length-to-diameter ratio of the screw is 30:1, and the extrusion temperature of the twin-screw extruder is: the first zone The temperature is 174°C, the temperature in the second zone is 186°C, the temperature in the third zone is 204°C, and the temperature in the four...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com