OCA optical adhesive tape

A technology of optical adhesive layer and adhesive tape, which is applied in the direction of adhesives, non-polymer adhesive additives, film/sheet adhesives, etc. It can solve the problems of poor heat resistance, rapid curing, difficult bonding, and difficult filling bonding and other problems, to achieve the effect of improving heat resistance, improving the brittleness of the adhesive layer, and increasing heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

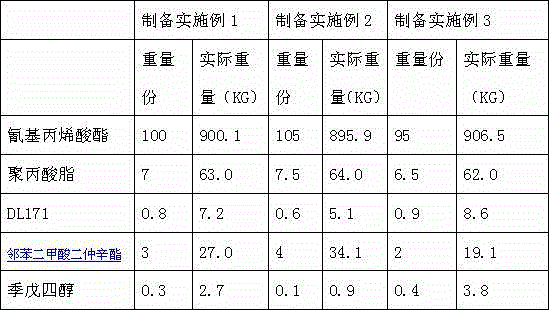

Method used

Image

Examples

experiment example

[0018]

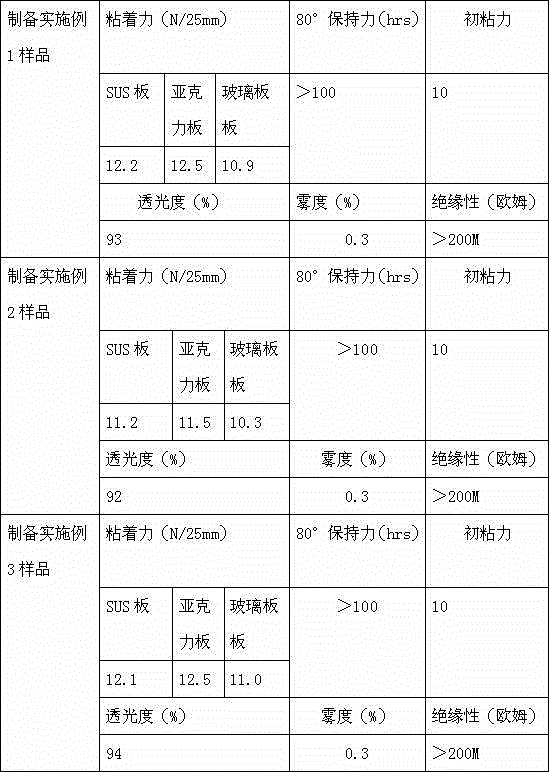

[0019] The OCA optical adhesive tape of the present invention has better bonding performance to various materials, such as SUS board, acrylic board, glass plate, etc., and the light transmission of the OCV optical adhesive tape is better, which solves the problem in the market. The existing liquid optical glue (LOCA), because the thickness is not easy to control, so the curing shrinkage is easy to generate bubbles. Moreover, it is easy to cause pollution and the technical problems of inconvenient operation, and it has better heat resistance, and the holding force is greater than 100 hours at a high temperature of 80°C, which solves the problem of poor heat resistance of ordinary acrylic optical adhesives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com