Coal low-temperature pyrolysis-combustion integrated gas tar preparation semi-coking system and method

A low-temperature pyrolysis and gas technology, which is applied in combustion methods, combustible gas purification, combustible gas purification/reconstruction, etc., can solve the problems of poor adjustment performance of pneumatic control valves, low flow rate of circulating materials, and complicated system operation, and achieves The effect of reducing internal ash concentration, reducing the rate of water wall wear, and sufficient heat recovery of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

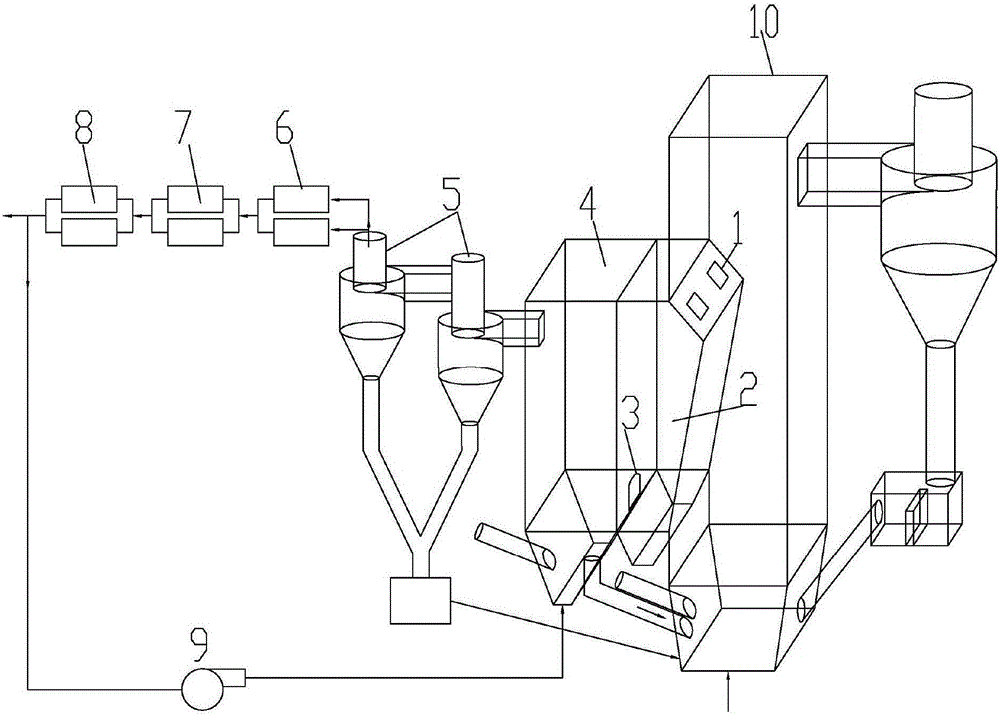

[0026] Such as figure 1 As shown, the coal low-temperature pyrolysis-combustion integrated system for producing gas tar and semi-coke includes: smokestack 1, moving bed 2, channel 3, coal low-temperature pyrolysis furnace 4, cyclone separator 5, ceramic filter 6, gas indirect Cooler 7, electric tar collector 8, gas recirculation fan 9, circulating fluidized bed combustion furnace 10.

[0027] The circulating fluidized bed combustion furnace 10 and coal low-temperature pyrolysis furnace 4 adopt an integrated design, and the circulating material in the circulating fluidized bed combustion furnace 10 enters the two smokestacks 1 on the upper part of the furnace through internal circulation, and then falls into the moving bed 2 Finally, it enters the low-temperature coal low-temperature pyrolysis furnace 4 after passing through a passage 3 at the lower part of the moving bed 2 . The coal enters the coal low-temperature pyrolysis furnace 4 through the feeder and is mixed with high...

Embodiment 2

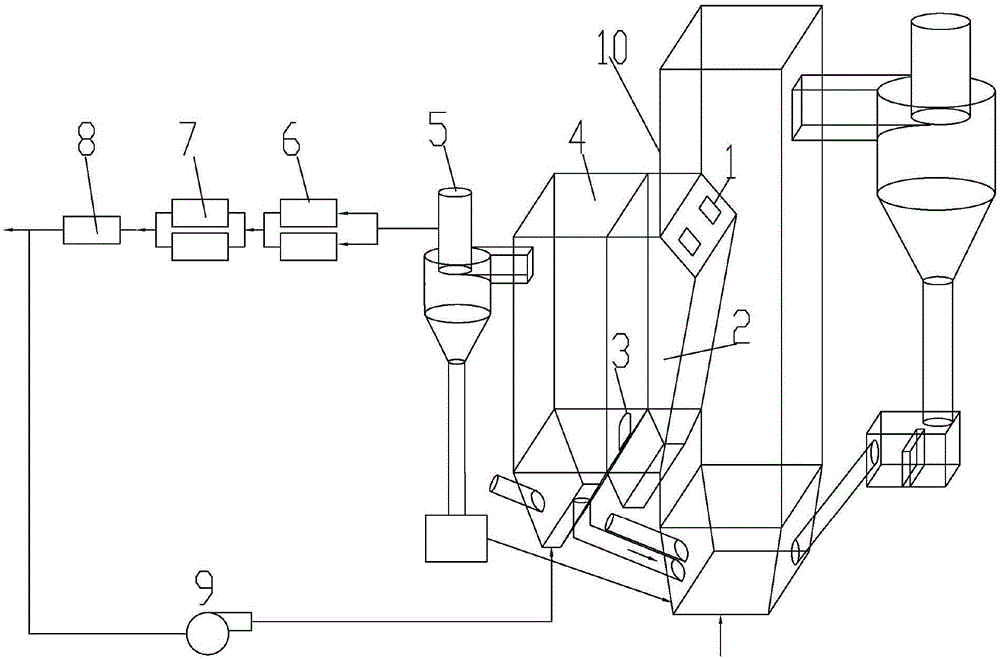

[0029] Such as figure 2 As shown, the coal low-temperature pyrolysis-combustion integrated system for producing gas tar and semi-coke includes: smokestack 1, moving bed 2, channel 3, coal low-temperature pyrolysis furnace 4, cyclone separator 5, ceramic filter 6, gas indirect Cooler 7, electric tar collector 8, gas recirculation fan 9, circulating fluidized bed combustion furnace 10.

[0030] The circulating fluidized bed combustion furnace 10 and the coal low-temperature pyrolysis furnace 4 adopt an integrated design, and the circulating material in the circulating fluidized bed combustion furnace 10 enters the two chimneys 1 in an internal circulation mode, falls into the moving bed 2, and passes through the moving bed. A channel 3 at the lower part of the bed 2 enters the low-temperature coal low-temperature pyrolysis furnace 4 . The coal enters the coal low-temperature pyrolysis furnace 4 through the feeder and mixes with the high-temperature circulating material to prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com