Preparation method of super-soft and highly-hygroscopic silk fibers

A silk fiber, high hygroscopic technology, applied in the direction of improved hand fiber, ultrasonic/sonic fiber treatment, fiber treatment, etc., can solve the problems of complicated preparation process, low technical content, green environmental protection pure natural fiber, etc. The method is simple, the effect of improving the hygroscopicity and retaining the gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

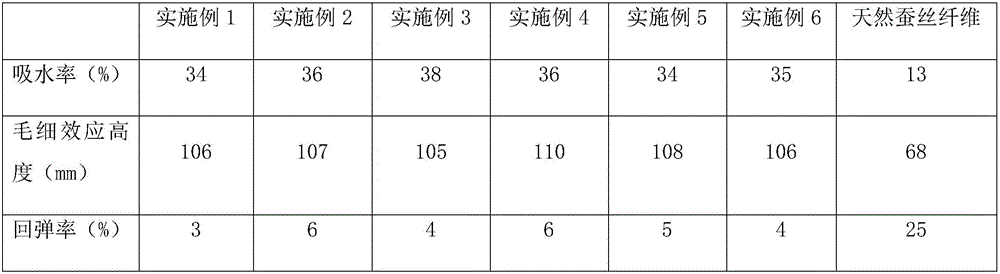

Examples

Embodiment 1

[0027] (1) After the silk fibers were boiled and degummed, they were immersed in warm water at 30°C for swelling treatment for 30 minutes, and then rubbed and rubbed at a frequency of 30 times / min for 1 minute at a strength of 1 N to obtain pretreated silk fibers.

[0028] (2) The pretreated silk fiber prepared in step (1) is immersed in a solution containing 10nm nano-hydrogel particles of 20g / ml, ultrasonically oscillated for 20min at a frequency of 100W, taken out, and dried to obtain a water content of 8 % of highly hygroscopic silk fibers.

[0029] (3) Add the highly hygroscopic silk fiber prepared in step (2) into ice water with a bath ratio of 1:40, heat and stir slowly, add S114 alkaline protease at 40 activity units / ml, and take it out after reacting at 35°C for 30 minutes. Fully wash, dry naturally to get super soft and highly hygroscopic silk fibers.

Embodiment 2

[0031] (1) After the silk fibers were boiled and degummed, they were immersed in warm water at 40°C for swelling treatment for 50 minutes, and then rubbed and rubbed at a frequency of 30 times / min for 10 minutes under a strength of 3N to obtain pretreated silk fibers.

[0032] (2) The pretreated silk fiber prepared by step (1) is immersed in the solution containing 100nm nano-hydrogel particles of 40g / ml, ultrasonically oscillated for 60min at a frequency of 150W, taken out, and dried to obtain a water content of 15 % of highly hygroscopic silk fibers.

[0033] (3) Add the highly hygroscopic silk fiber prepared in step (2) into ice water with a bath ratio of 1:40, heat and stir slowly, add 60 activity units / ml of 2709 alkaline protease, and take it out after reacting at 40°C for 90 minutes. Fully wash, dry naturally to get super soft and highly hygroscopic silk fibers.

Embodiment 3

[0035] (1) After the silk fibers were boiled and degummed, they were immersed in warm water at 35°C for swelling treatment for 40 minutes, and then rubbed and rubbed at a frequency of 30 times / min for 5 minutes at a strength of 2N to obtain pretreated silk fibers.

[0036] (2) The pretreated silk fiber prepared by step (1) is immersed in the solution containing 50nm nano-hydrogel particles of 30g / ml, ultrasonically oscillated for 30min at a frequency of 120W, taken out, and dried to obtain a water content of 10 % of highly hygroscopic silk fibers.

[0037] (3) Add the highly hygroscopic silk fiber prepared in step (2) into ice water with a bath ratio of 1:40, heat and stir slowly, add S114 alkaline protease at 50 activity units / ml, and take it out after reacting at 40°C for 60 minutes. Fully wash, dry naturally to get super soft and highly hygroscopic silk fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com