rotary piston engine

A technology of rotary piston and engine, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problems of many vulnerable parts, low mechanical efficiency and high manufacturing cost, achieve low vibration and noise, and save production costs , the effect of high mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

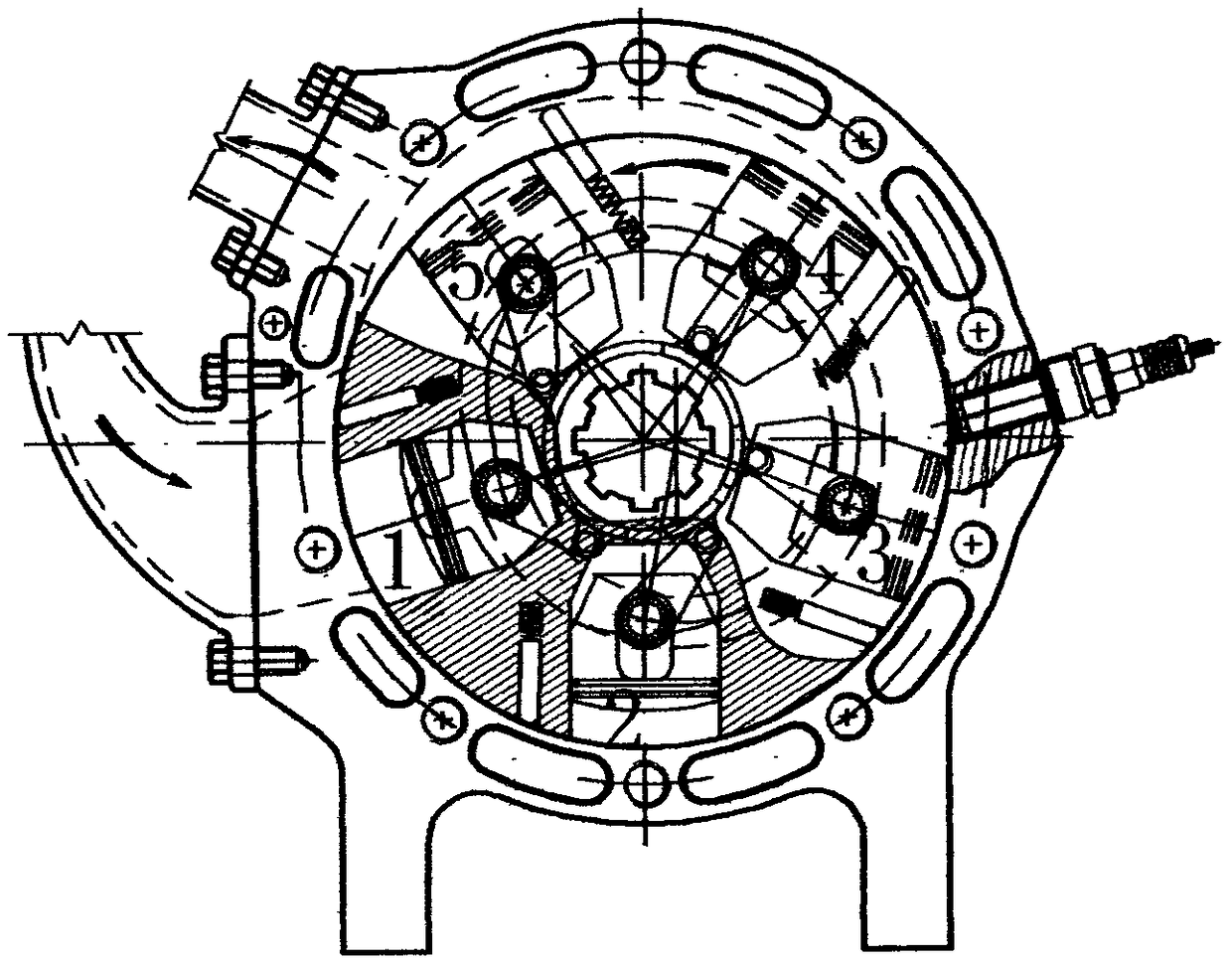

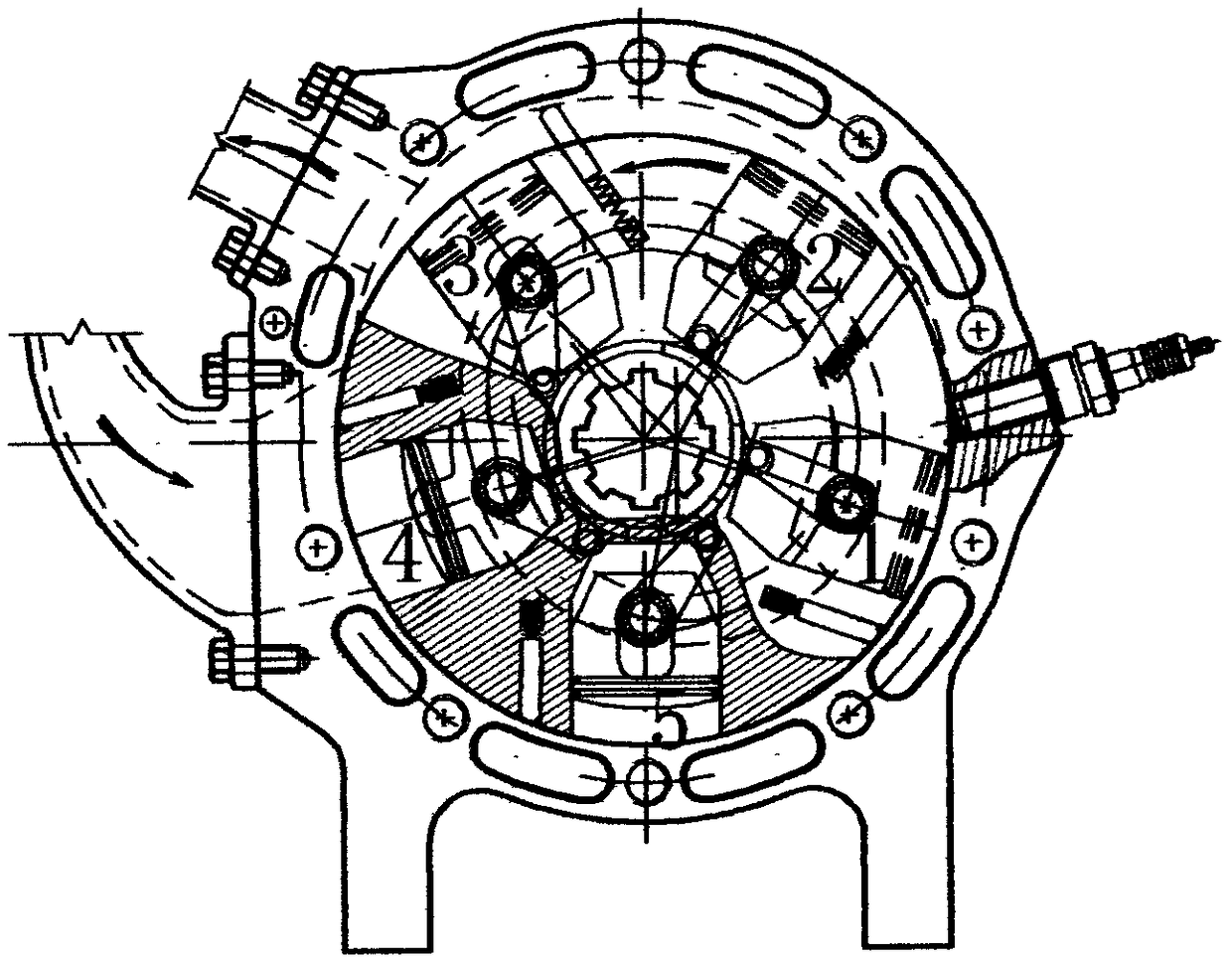

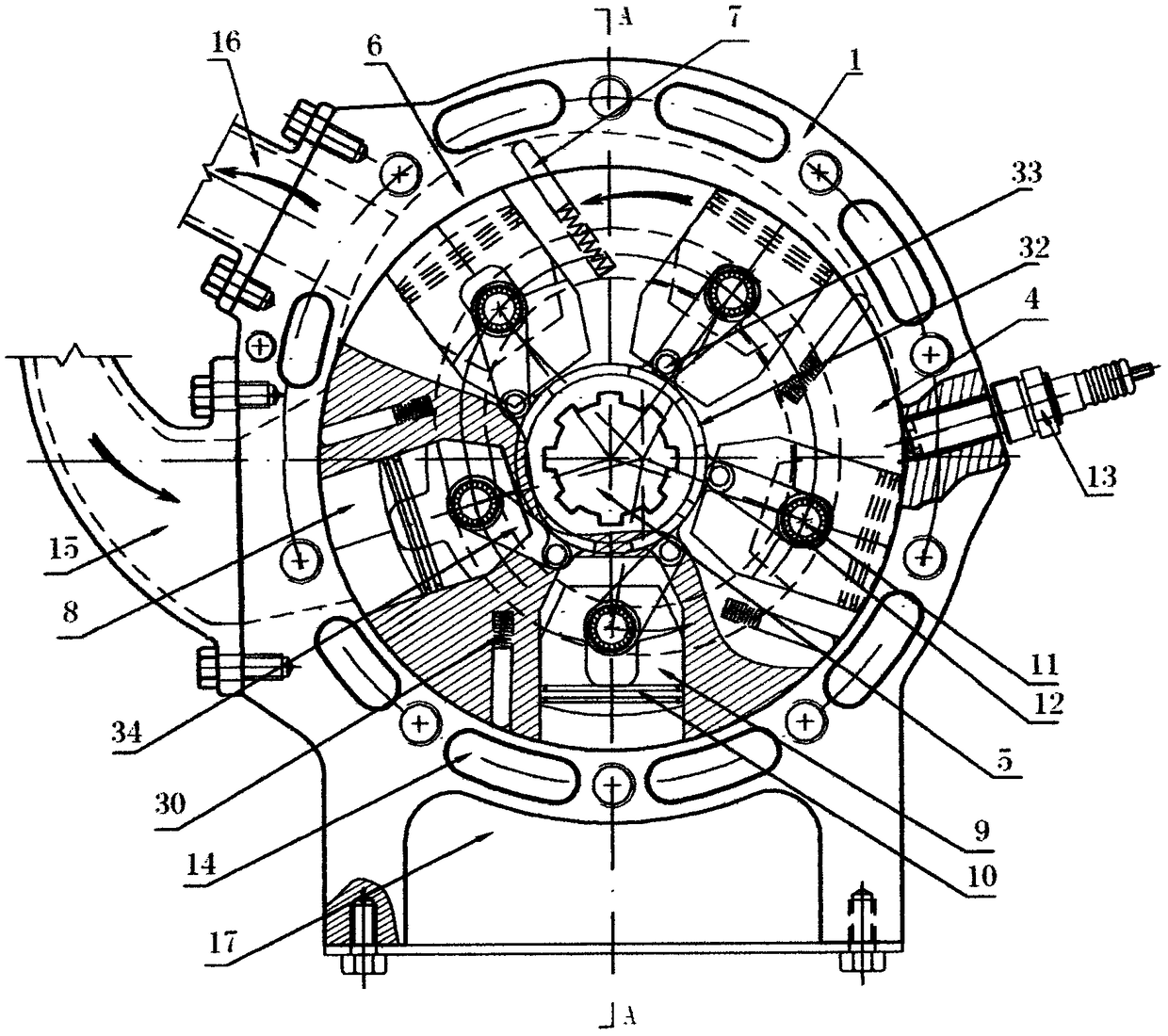

[0027]With reference to above-mentioned accompanying drawing, a kind of rotary piston engine comprises cylinder body 1, front and rear end cover 2,3 synthetic housing; Proper position on cylinder body is respectively provided with intake and exhaust channel 15,16, spark plug 13, cooling cycle Waterway 14 and oil tank 17, the cooling circulation waterway 14 is provided with inlet 27 and outlet 28; rear end cover 3 is equipped with oil pump 21, driven gear shaft 22, driven gear 24 and rear end cover main bearing 25, front end cover 2 The main bearing 26 of the front end cover is installed, and the front end cover 2 is provided with a cooling circulation channel rotor 4 and a driving gear 23 mounted on the engine main shaft 5; it is characterized in that there are no N pistons 9 and N piston pins 11 in the rotary piston engine The two ends of the piston pin are fitted with a connecting rod 34, the other end of which is connected to the thrust head 33, and the thrust head 33 is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com