Valve with filtering function

A valve and function technology, applied in the direction of filtration separation, sliding valve, valve device, etc., can solve the problems of short service life, easy valve blockage, increased operation, etc., to achieve uniform utilization and loss, improve filtration efficiency, and reduce cleaning costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

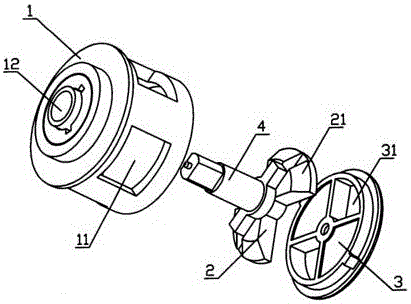

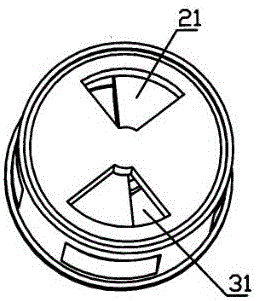

[0022] Such as figure 1 and 2 , the inner cavity of the shell 1 of the valve with filtering function is cylindrical, and four water inlets 11 are distributed on the side wall of the shell 1, and the water volume control mechanism is located at the end of the inner cavity of the shell 1. The water volume control mechanism is mainly composed of a valve stator 3 and a valve rotor 2. The valve stator 3 is installed in cooperation with the annular step at the end of the inner cavity of the casing 1. Two fan-shaped liquid flow ports 31 are symmetrically distributed on both sides of the valve stator 3 axis. One end face of the valve rotor 2 fits with the valve stator 3 and can rotate relative to the valve stator 3. The valve rotor 2 is two blocks 21 distributed symmetrically to its axis. When the flow port 31 is used, the liquid flow port 31 can be blocked to prev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com