Method for evaluating elasticity of oil well cement stone

A technology for oil well cement and cement stone, which is applied in the preparation of test samples, the application of stable tension/pressure to test the strength of materials, sampling, etc. , the effect of simple experiment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

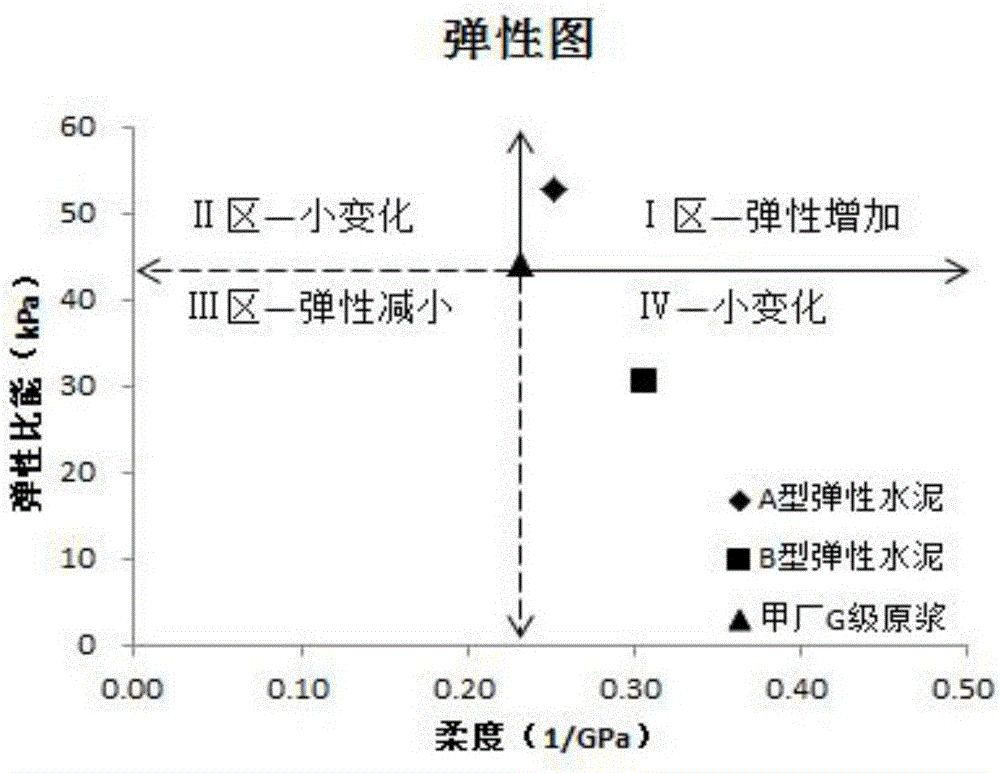

Embodiment 1

[0039] The G-grade cement of factory A has undergone two kinds of elastic toughness transformations, A and B, and formed A-type elastic cement and B-type elastic cement. The A and B elastic cements are used to prepare 1.45g / cm 3 The cement slurry system was tested at a temperature of 60°C and a pressure of 20.7MPa to evaluate the effect of elastic modification. With the evaluation method of the present invention, 3 curing times of 2 days, 7 days and 14 days are designed, and the uniaxial compression experiment of cement stone is done with the high-temperature and high-pressure rock triaxial instrument RTR1000 of U.S. GCTS company without enclosing. The elasticity of the two modified cements was compared with the original slurry, the experimental data are shown in Table 1, and the comparison conclusions are as follows image 3 .

[0040] Table 1. Experimental data for evaluating the elastic transformation effect of Grade G cement in Plant A (the density of cement slurry is 1.4...

Embodiment 2

[0043] The G-grade cement of Plant B has undergone two elastic toughness transformations of C and D to form C-type elastic cement and D-type elastic cement, and the C and D elastic cements are used to prepare 1.90g / cm 3 The cement slurry system was tested at a temperature of 60°C and a pressure of 20.7MPa to evaluate the effect of elastic modification. With the evaluation method of the present invention, 3 curing times of 2 days, 7 days and 14 days are designed, and the uniaxial compression experiment of cement is done with the high-temperature and high-pressure rock triaxial instrument RTR1000 of U.S. GCTS company without enclosure, and C, D The elasticity of the two modified cements was compared with the original slurry, the experimental data are shown in Table 2, and the comparison conclusions are as follows Figure 4 .

[0044] Table 2 The experimental data of the evaluation of the elastic transformation effect of G grade cement in Plant B (the density of cement slurry is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com