A kind of cellulose paper/bi2te3 thermoelectric film composite material and its preparation method

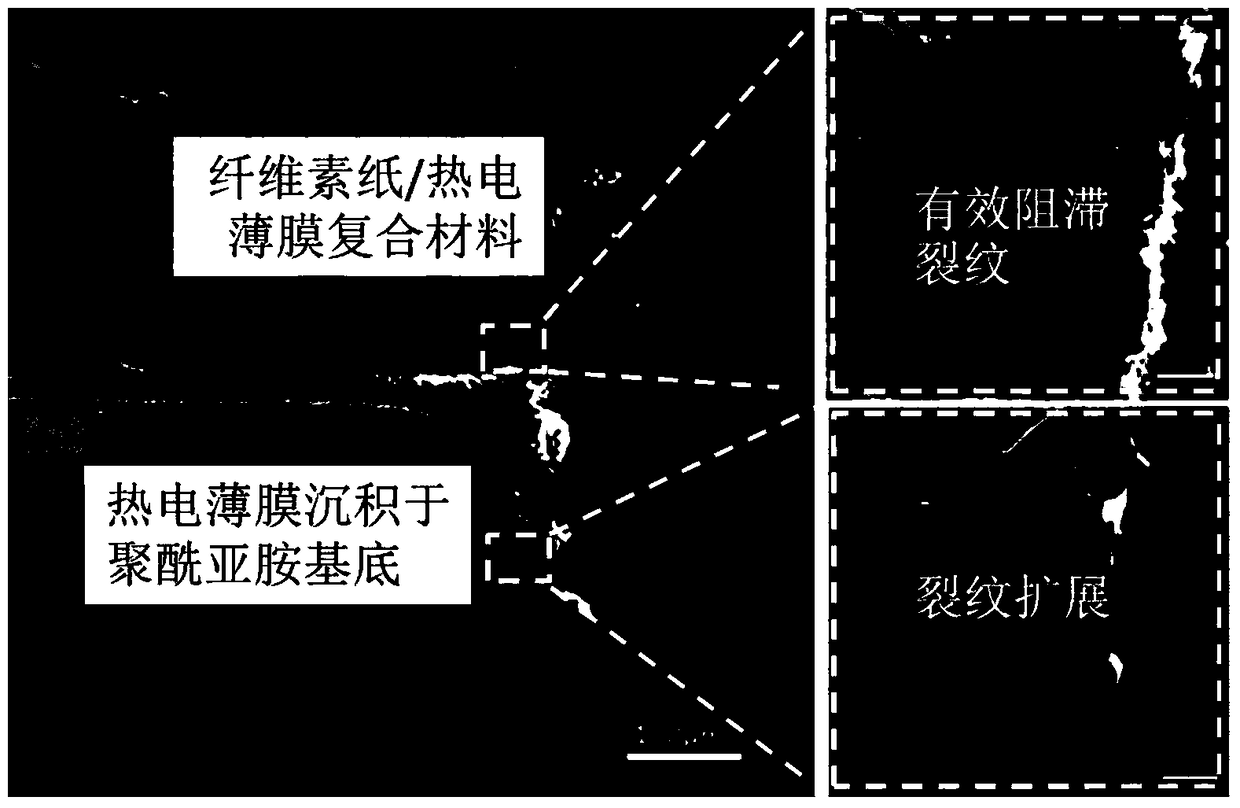

A technology of cellulose paper and thermoelectric film, which is applied in the field of composite materials, can solve the problems of low melting point and easy change of components, and achieve the effects of improving thermoelectric performance, good ability to retard crack propagation, and high compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

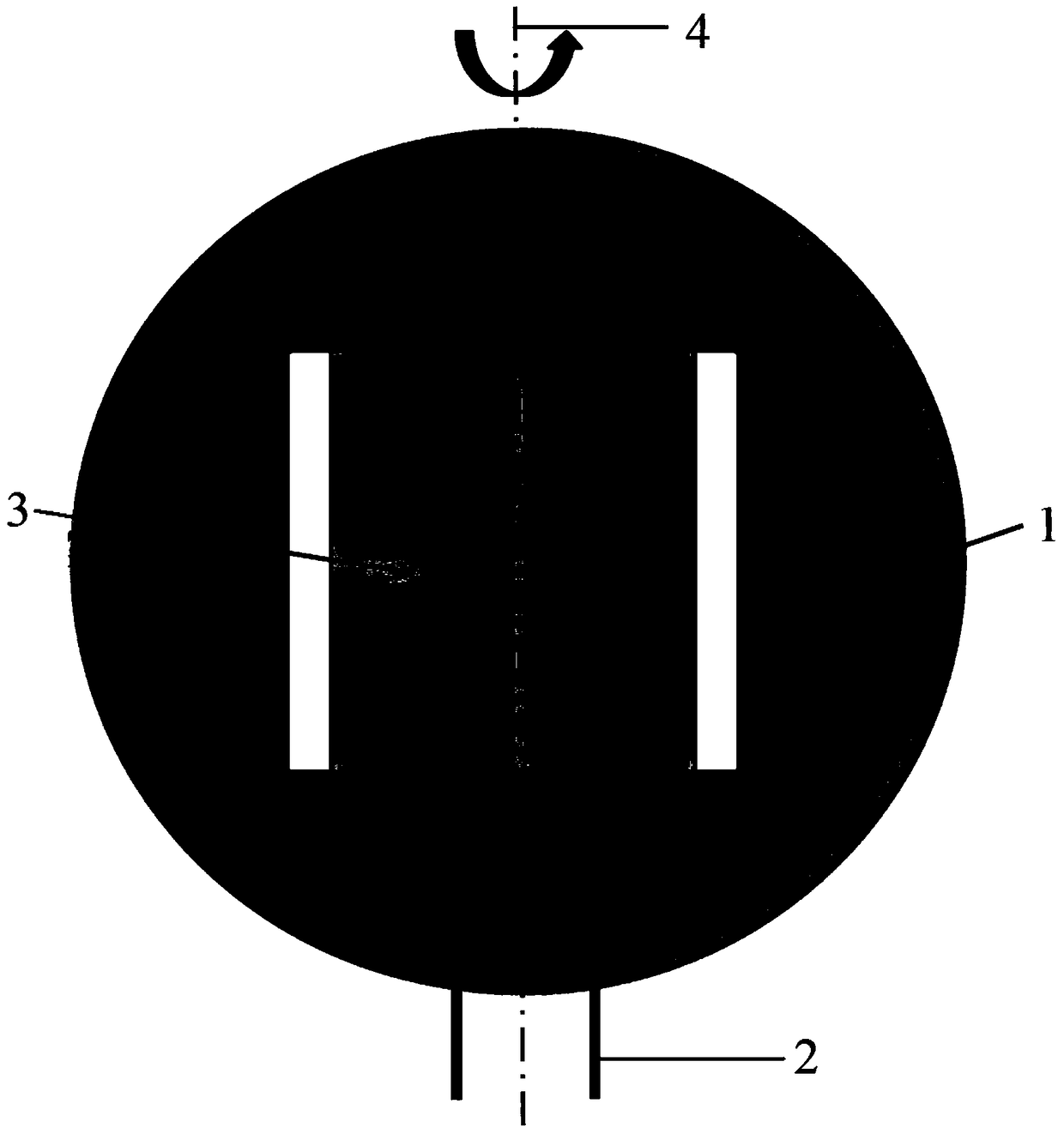

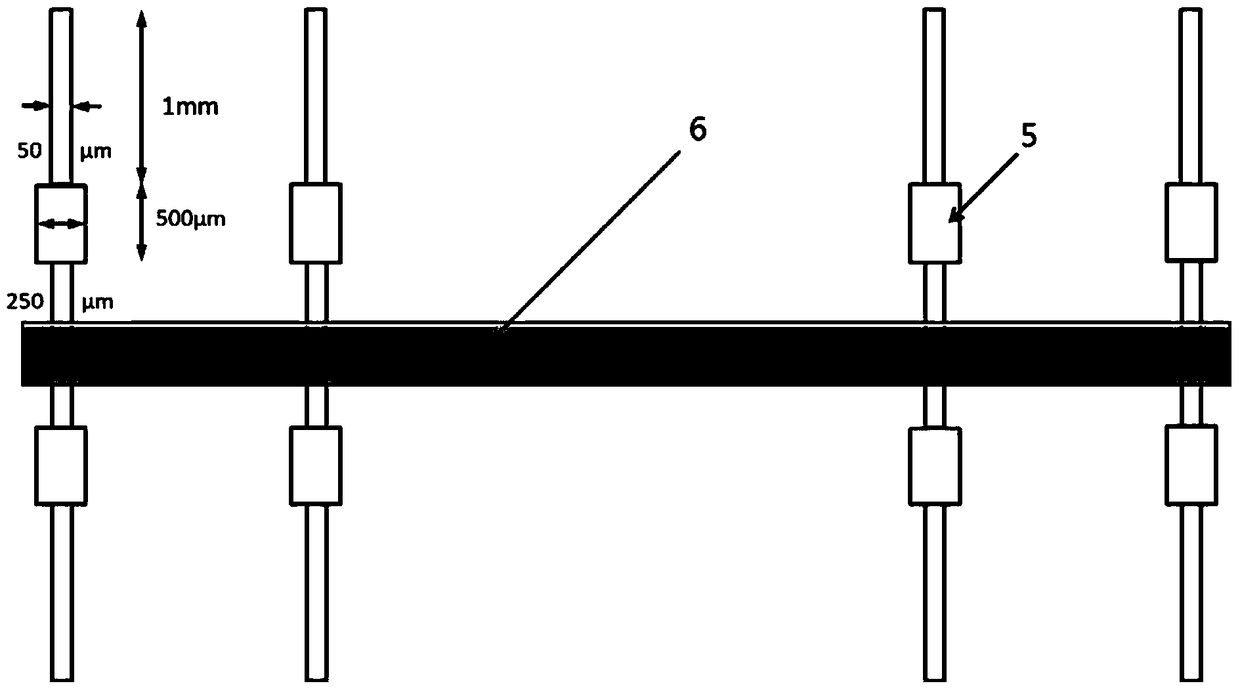

[0034] In the specific implementation process, the cellulose paper of the present invention / Bi 2 Te 3 Thermoelectric thin film composites comprising a cellulose paper substrate with Bi uniformly deposited on its surface 2 Te 3 Thermoelectric thin film layer, forming cellulose paper -Bi 2 Te 3 Thermoelectric thin film layer structure. Among them, the thickness of the cellulose paper is 50-100 μm, and the cellulose paper is composed of a large number of cellulose fibers with randomly distributed orientations and diameters ranging from hundreds of nanometers to 10 microns (generally 0.5-10 μm). The fiber length is 100-500 μm, and has good bending resistance and flexibility. The grain size of the film layer deposited on the cellulose paper can vary in the range of 90-520nm according to the deposition temperature, the crystal quality is high, there is no observable nano-hole structure and other defects, and the composition is uniform and adjustable. Bi 2 Te 3 The nominal th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com