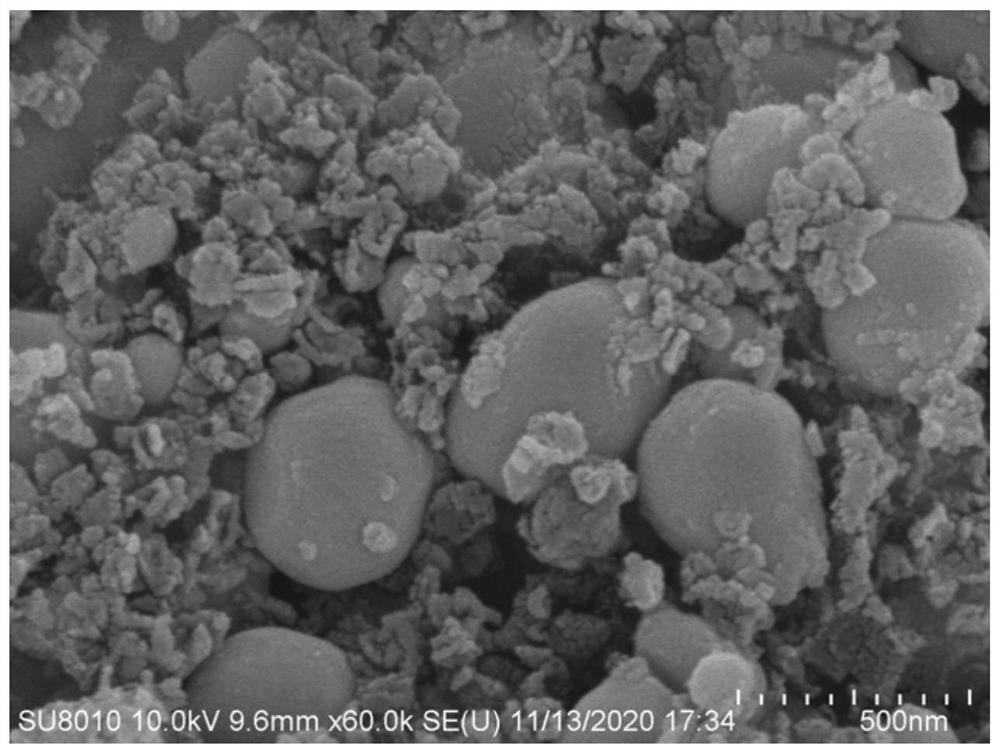

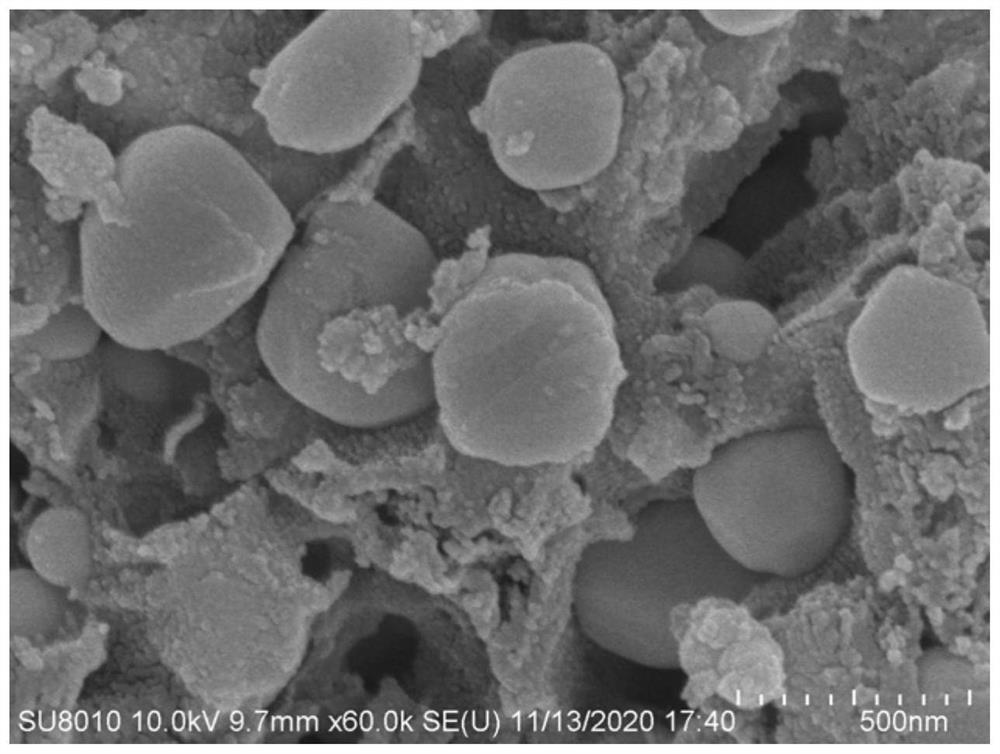

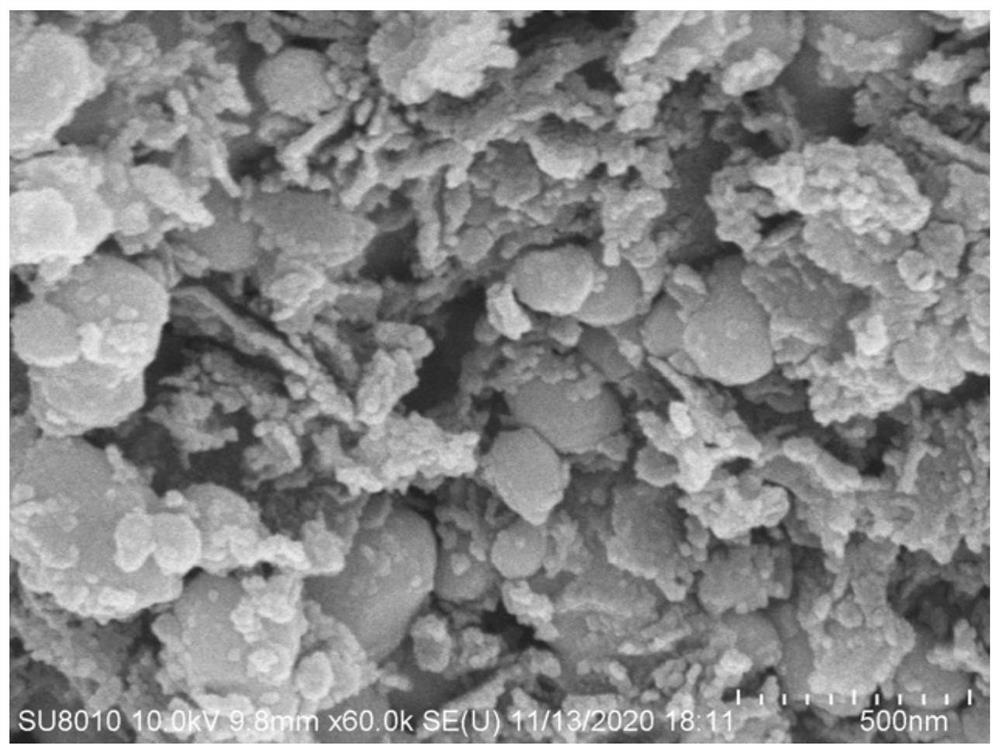

Preparation method and application of MOF-derived CuAl/N-C catalyst

A catalyst and cual-mofs technology, which is applied in the preparation and application of MOF-derived CuAl/N-C catalysts, can solve the problems of precise control or substitution of bimetallic difficult atoms, low current density, and poor Faraday efficiency, etc., to improve the product selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0034] Specific embodiment one: present embodiment a kind of preparation method of CuAl / N-C catalyst derived from MOF, it is finished according to the following steps:

[0035] 1. Weighing:

[0036] Weighing deprotonating reagent, organic solvent, ligand, copper salt and aluminum salt;

[0037] The volume ratio of the amount of the substance of the deprotonating reagent to the organic solvent is (1.2~7.2)mmol:35mL; the volume ratio of the amount of the substance of the ligand to the organic solvent is (0.3~1.2)mmol: 35mL; the mol ratio of the copper salt and the aluminum salt is (0.1~99):1; the volume ratio of the sum of the amount of the copper salt and the aluminum salt to the organic solvent is (1.2~2.4)mmol: 35mL;

[0038] 2. Preparation of precursor salt solution:

[0039] Dissolving the ligand, copper salt and aluminum salt weighed in step 1 in an organic solvent to obtain a precursor salt solution;

[0040] 3. Preparation of CuAl-MOFs:

[0041] Adding the deprotona...

specific Embodiment approach 2

[0050] Embodiment 2: This embodiment differs from Embodiment 1 in that the deprotonating reagent described in step 1 is sodium hydroxide, triethylamine or sodium methoxide. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0051] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the copper salt described in step one is Cu(CH 3 COO) 2 , CuCl 2 2H 2 O or Cu(NO 3 ) 2 ·3H 2 O. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com