Semiconductor laser based on anisotropic substrate

An anisotropy and laser technology, applied to semiconductor lasers, structural details of semiconductor lasers, lasers, etc., can solve problems such as low heat conduction efficiency and complex packaging process, and achieve simplified manufacturing process steps, improved heat dissipation efficiency, and improved products performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

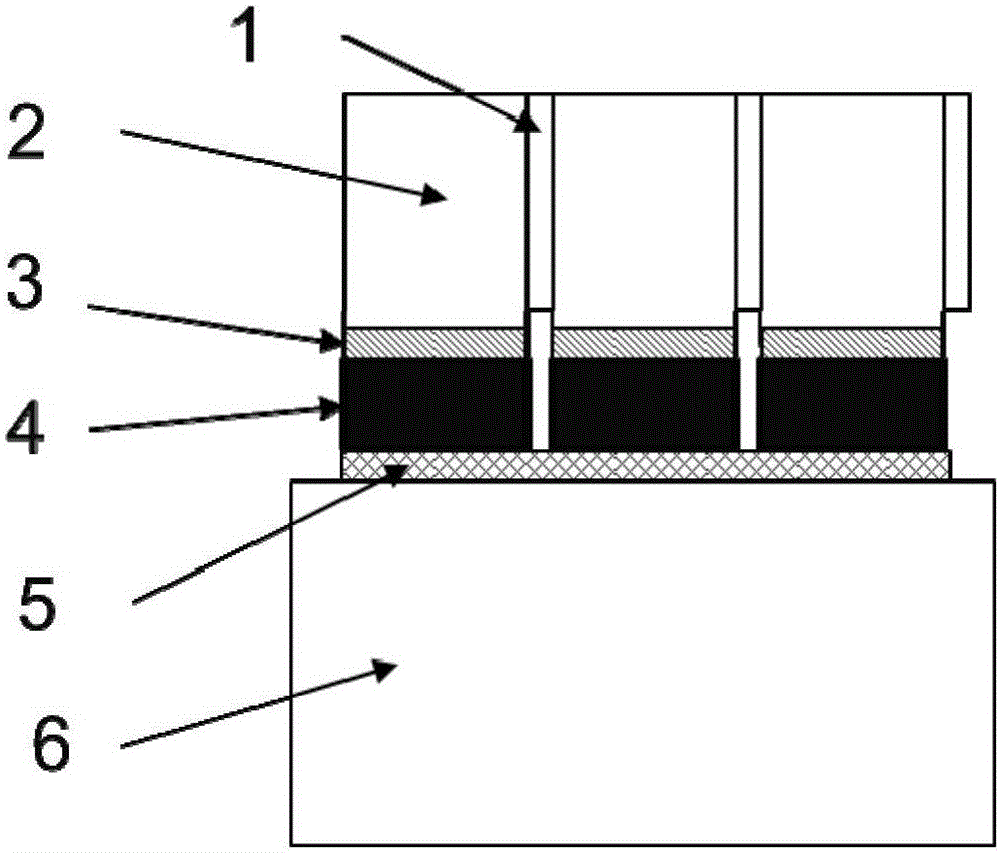

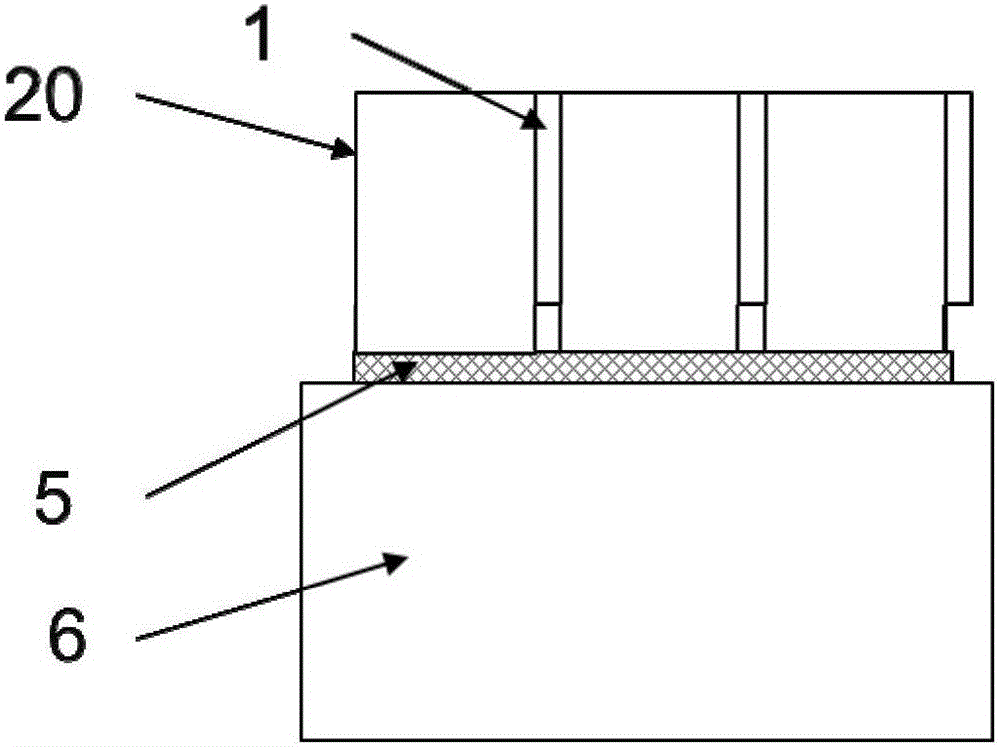

[0037] Such as figure 2 As shown, the laser chip 1 is assembled on a substrate 20 with high thermal conductivity and CTE matching, and one or more laser chips and the corresponding substrate are assembled and bonded to the radiator 6 through solder 5 to form a semiconductor laser. The substrate has conductivity in the chip stacking direction (the conductive area covers at least the chip bonding area), and has insulation in the direction perpendicular to the surface of the heat sink.

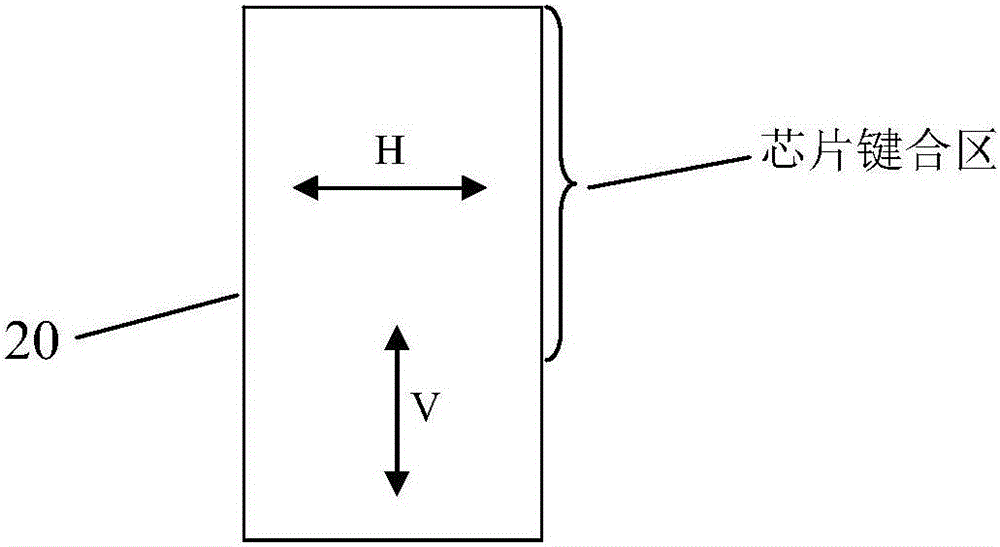

[0038] Such as image 3 , the substrate 20 is a composite body composed of insulating materials and conductive materials. The insulating material and the conductive material are closely combined. Such an integrated substrate realizes both conduction and insulation. Compared with the existing conductive substrate plus insulating block bonding The combination of two bonded interfaces and a solder layer (5 to 10 microns thick) are reduced. The layout of the insulating material and the conductive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com