Oil composition replacing beef tallow and preparation method thereof

A technology of oil composition and tallow, which is applied in the field of oil production and can solve problems such as less research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

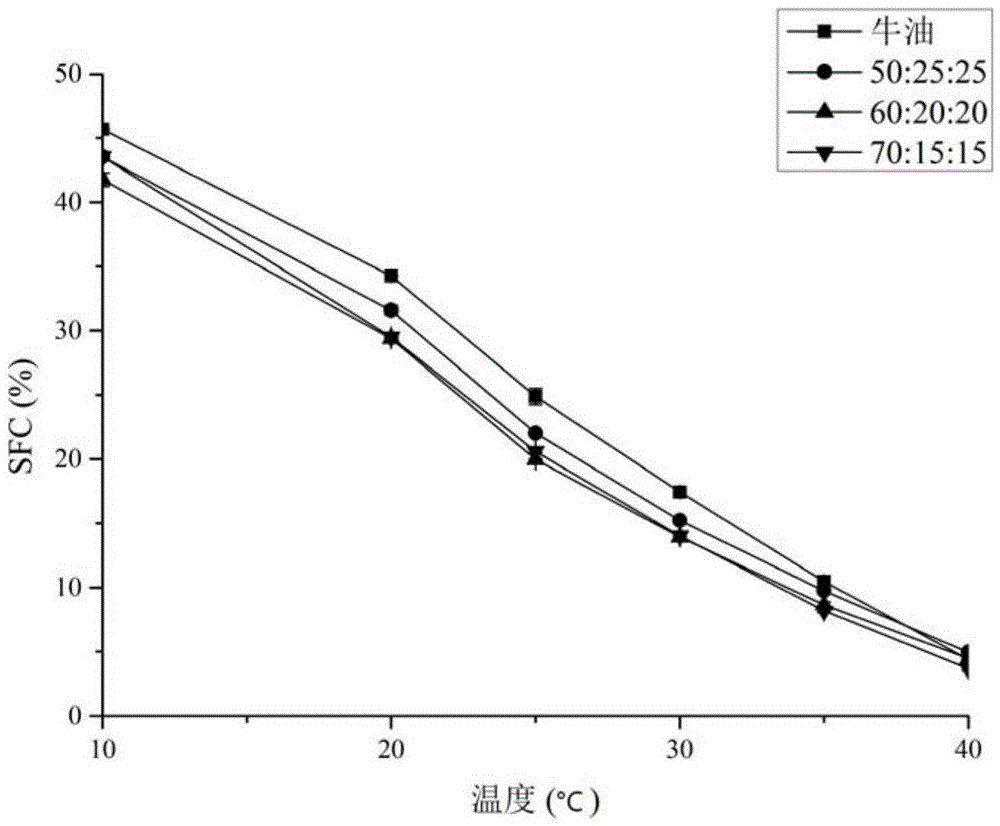

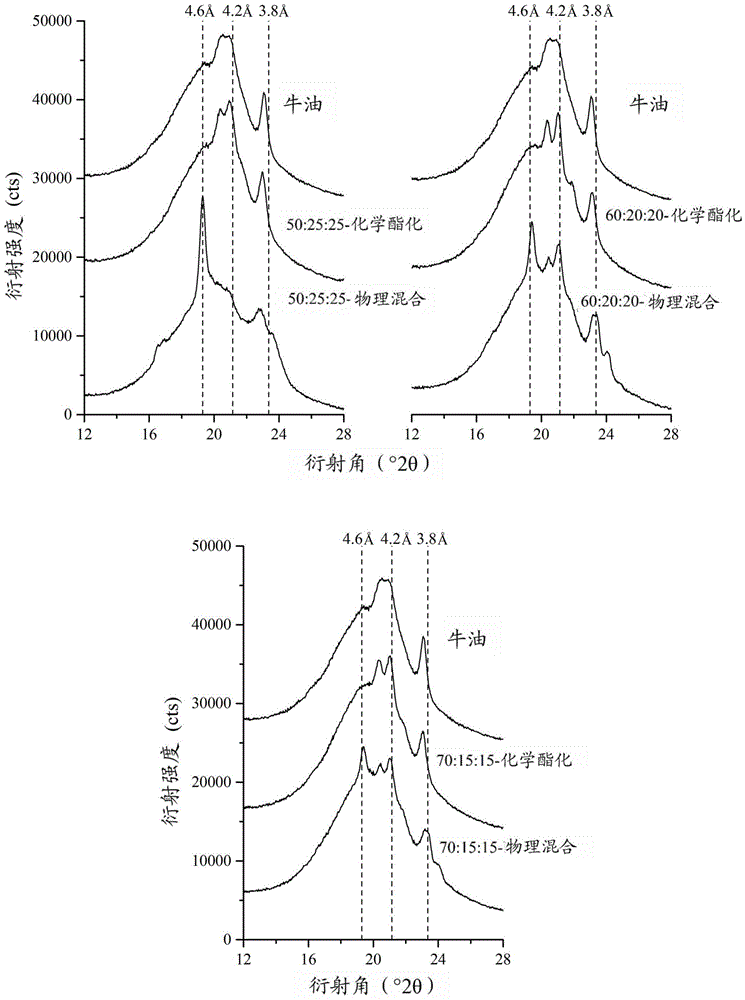

[0142] Example 1: Oil and fat mixing ratio design and property analysis of chemical transesterification products

[0143] The acid value (AV) and the peroxide value (PV) of raw material oil and fat used in the following examples palm olein (OL), fully hydrogenated soybean oil (FHSBO), canola oil (canola), tallow and peroxide value (PV) are as in table 1 Shown:

[0144] Table 1. Physical and chemical indicators of raw oils and fats

[0145]

[0146] According to the fatty acid composition of three selected vegetable oils OL, FHSBO and Canola and tallow, the mixing ratio of vegetable oil with fatty acid composition close to that of tallow was designed. In this embodiment, three kinds of proportioning are selected:

[0147] Sample 1 - OL:FHSBO:Canola = 50:25:25,

[0148] Sample 2 - OL:FHSBO:Canola = 60:20:20,

[0149] Sample 3-OL:FHSBO:Canola=70:15:15.

[0150] The specific results are shown in Table 2.

[0151] The range of the fatty acid relative content of table 2 oil a...

Embodiment 2

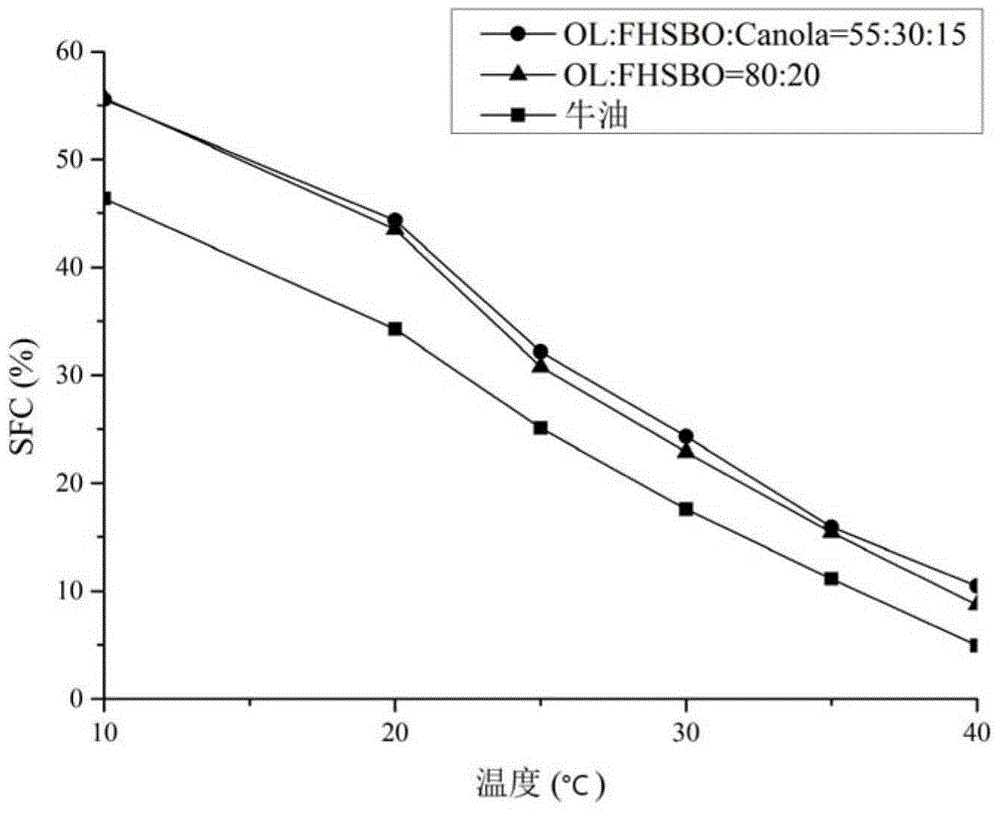

[0167] Embodiment 2. Utilize three kinds of vegetable oil mixtures and two kinds of vegetable oil mixtures with fatty acid composition similar to tallow to prepare transesterified oil

[0168] In this example, another ratio of palm olein, fully hydrogenated soybean oil and canola oil with fatty acid composition similar to that of tallow was designed, namely OL:FHSBO:Canola=55:30:15 (sample 4). In addition, the present application also designed a scheme of only palm olein and fully hydrogenated soybean oil raw materials whose fatty acid composition is similar to tallow, and its proportion is OL:FHSBO=80:20 (sample 5). The above two schemes and the fatty acid composition of tallow are shown in Table 5.

[0169] The fatty acid relative content of table 5 oil and the scope of the fatty acid relative content of tallow [15] (unit:%)

[0170]

[0171]

[0172] Note: a means not detected; b means lack of relevant data.

[0173] It can be seen from Table 5 that the fatty acid ...

Embodiment 3

[0183] Example 3. Proportion optimization of palm olein, fully hydrogenated soybean oil and canola oil and property analysis of transesterification products

[0184] The results of samples 1-3 in Example 1 were analyzed and optimized in detail. Further optimization was carried out according to the ratio of samples 2 and 3, and scheme 1 was obtained: OL:FHSBO:Canola=62:22:16. In addition, the proportion of sample 1 was retained as scheme 2: OL:FHSBO:Canola=50:25:25.

[0185] The chemical transesterification reaction was carried out according to the above mixing ratio and the chemical transesterification reaction described in the "Materials and Methods" section involved in Example 1 to obtain transesterification products.

[0186] Figure 4 The SFC curves of the transesterified oil products of schemes 1 and 2 are shown and compared with the SFC curves of beef tallow.

[0187] Such as Figure 4 As shown, the SFC curves of the transesterified oil products of schemes 1 and 2 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com