Preparing and regenerating methods of hydrophobic coating activated carbon capable of improving adsorption to water-containing organic gas

A technology of gas adsorption and activated carbon, which is applied in the field of environmental pollutant treatment, can solve the problems of weakening the adsorption of activated carbon and weakening the adsorption of target substances, and achieve the effects of increasing adsorption capacity, simple preparation and regeneration methods, and easy operation and promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 activated carbon modification and modified activated carbon characterization

[0027] The present embodiment provides the preparation method of hydrophobic modified activated carbon of the present invention, and its steps are as follows:

[0028] Step 1: Take 200ml of the prepared PDMS and put it into a stainless steel container, and place a wire mesh (aperture about 200 mesh) at 5cm above the liquid surface.

[0029] Step 2: Weigh 2.00g of activated carbon that has been pretreated (heated at 250°C for one hour) and evenly spread it on the surface of the wire mesh.

[0030] Step 3: After sealing the stainless steel container, put it into a muffle furnace for heating, heat at 250°C for 1 hour, seal it at room temperature and cool naturally to obtain hydrophobic modified activated carbon.

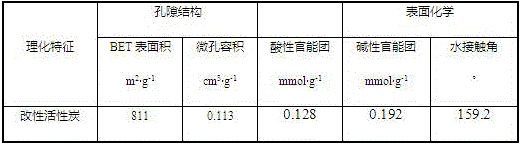

[0031] The results of characterization of activated carbon by BET, Boehm titration and other methods are listed in Table 1.

[0032] Table 1 Physical and chemical charac...

Embodiment 2

[0034] Embodiment 2. Modified active carbon is to toluene, the saturated adsorption of benzene

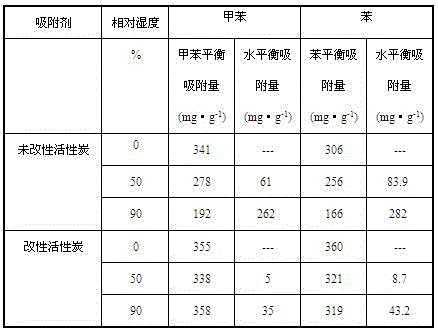

[0035] Table 2 lists the equilibrium adsorption capacity and equilibrium water vapor adsorption capacity of modified activated carbon for adsorption of aqueous VOCs. It shows the selective adsorption capacity of modified activated carbon to toluene and benzene molecules in the presence of water vapor.

[0036] Table 2 Equilibrium adsorption capacity and equilibrium water vapor adsorption capacity of modified activated carbon for adsorption of water-containing VOCs

[0037]

Embodiment 3

[0038] Embodiment 3 modified activated carbon regeneration

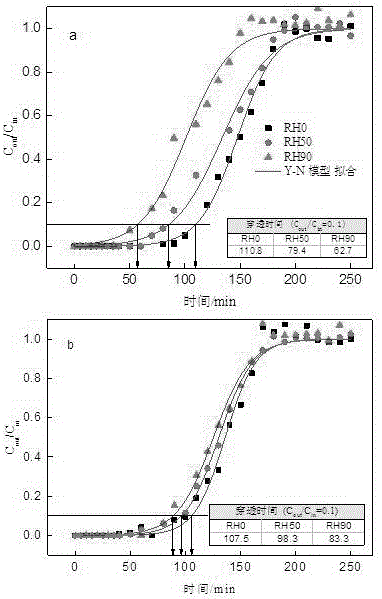

[0039] Take about 2.0g of VOCs (toluene, benzene) adsorption saturated activated carbon (activated carbon before modification and modified activated carbon in Example 1), spread evenly on the aluminum foil paper, and put it into the tube furnace. Nitrogen gas was introduced into the tube furnace at room temperature, and after the nitrogen gas filled the tube furnace, the tube furnace was turned on, the temperature was adjusted to 200°C, and nitrogen protection was continuously supplied, and heated for 8 hours. The adsorption breakthrough curve of regenerated activated carbon for benzene vapor is as follows: figure 1Shown; The equilibrium adsorption capacity of water vapor and benzene vapor of regenerated activated carbon is listed in Table 3. Adsorption of water-containing benzene vapor saturated modified activated carbon (unmodified) after regeneration, the benzene vapor adsorption capacity decreased very little. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com