Novel disc roller-type crusher

A roll crusher, a new type of technology, is applied in the direction of grain processing, etc., which can solve the problems of short equipment life, high cost, economic consumption and energy waste, and achieve the effects of improving work efficiency, crushing quickly, and ensuring safety and sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

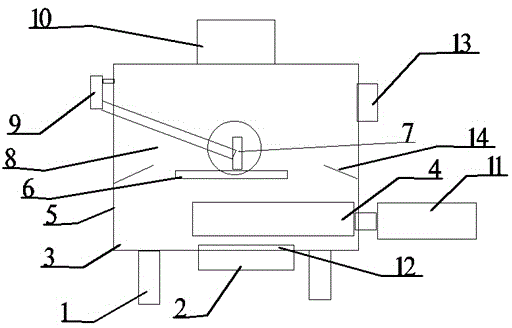

[0020] Example 2 as figure 1 As shown, it is improved on the basis of Embodiment 1. Its power disc 6 is driven to rotate by the main motor 11 through the speed reducer 4, and the speed reducer 4 bears the crushing force as the supporting part of the power disc 6 simultaneously. The power plate bears a large crushing force, and at the same time, the reducer adjusts the gear speed, so that the high speed becomes a large stress power, so that the power of the crusher is greater. The high speed and low stress of the motor is converted by the reducer into low speed and high stress, which is applied to the crushed material.

Embodiment 3

[0022] Example 3 as figure 1 As shown, it is improved on the basis of Embodiment 1, and its base 3 top is provided with screen 12, and screen 12 is made of stainless steel, and the aperture of screen is 7mm. Through the sieve, the smaller qualified granular material products can pass through the sieve, and the larger particles continue to go through a crushing process until the particle size meets the requirements, the material will all pass through, ensuring the quality of work.

Embodiment 4

[0024] Example 4 as figure 1 As shown, it is improved on the basis of Example 1. Its shell 5 is provided with a back pressure dust collector 13 on one side, and the back pressure dust collector 13 is a closed dust collector, and the dust accumulation pipeline leads to the slag ditch . Use a dust collector to remove dust to ensure a safe and hygienic working environment. At the same time, the dust is safely discharged through the pipeline without causing pollution, which is safe and environmentally friendly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com