Preparation method of silver nanoparticles

A technology of silver nanoparticles and preparation steps, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve the problems of difficult large-scale production, complicated preparation process, high preparation cost, etc., achieve low cost, simple preparation process, The effect of short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

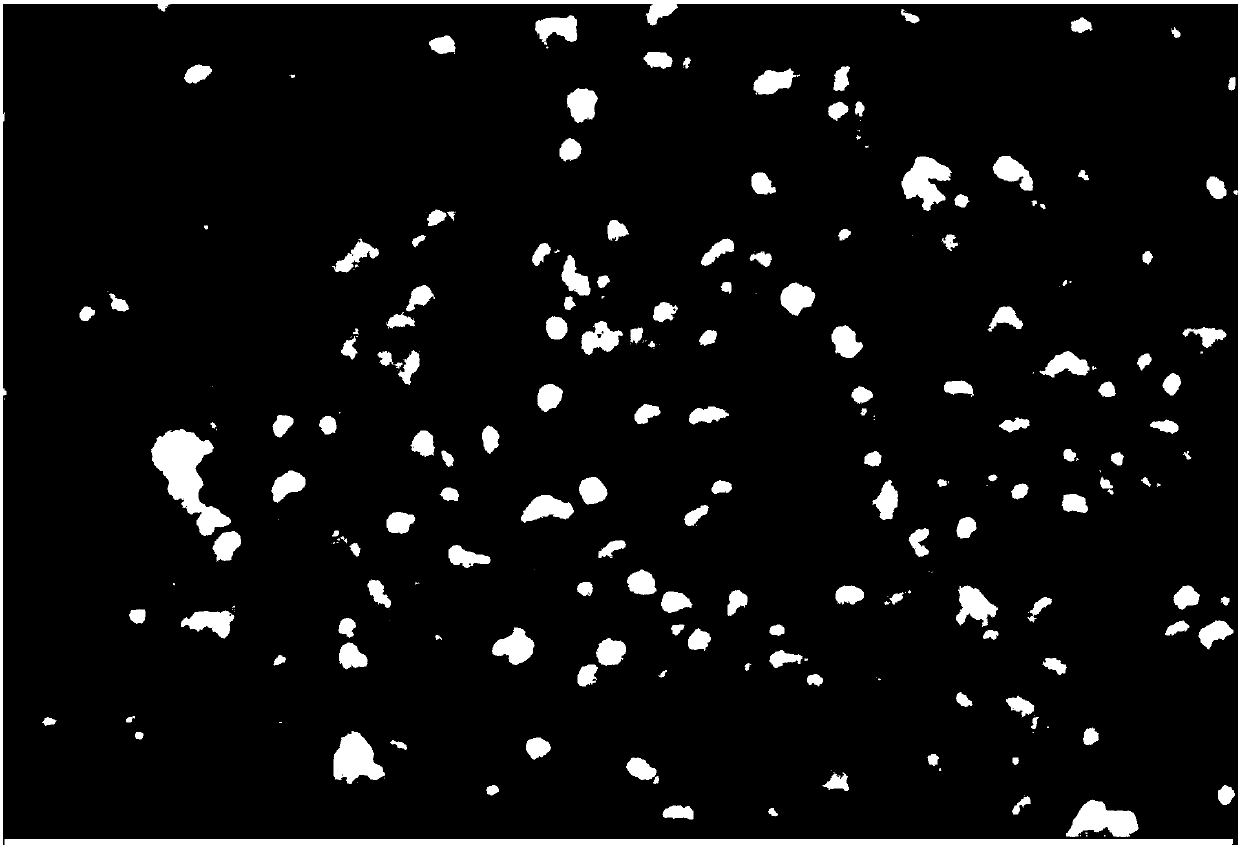

[0029] refer to figure 1 Shown is a preferred embodiment provided by the present invention.

[0030] The preparation method of the silver nanoparticles provided by the present embodiment comprises the following steps:

[0031] 1), weigh silver nitrate (AgNO3) and water-soluble stabilizer, and place silver nitrate (AgNO3) and stabilizer in reaction container, as beaker etc.;

[0032] 2), add water in reaction vessel;

[0033] 3), at room temperature and normal pressure and in an environment with light, electromagnetically stir the solution in the reaction vessel until the color of the solution turns red, that is, silver nanoparticles are formed in the solution;

[0034] 4) After the reaction of the solution in the reaction vessel in step 3) is completed, store the solution in the reaction vessel containing the solution in the dark, and then extract the silver nanoparticles in the solution.

[0035] In the preparation method of silver nanoparticles provided above, only water ...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is:

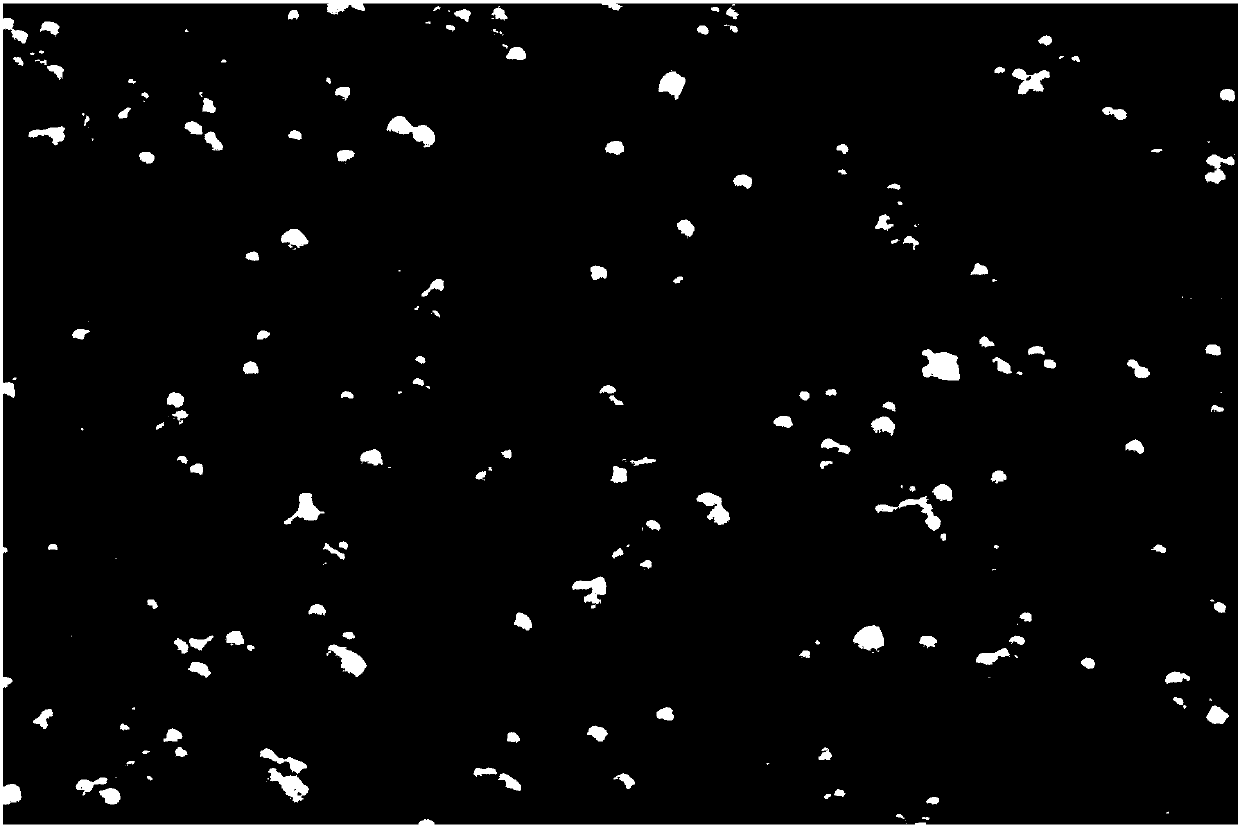

[0053] refer to figure 2 Shown is a schematic diagram of the silver nanoparticles obtained in this example.

[0054] Weigh 17.4mg of silver nitrate, then weigh 55.4mg of polyvinylpyrrolidone (Mr~10000), the molar ratio of silver nitrate to polyvinylpyrrolidone is about 1:5, add 20ml of water, and fully dissolve under electromagnetic stirring in an environment with natural light. Silver nitrate and polyvinylpyrrolidone were dissolved in water to form a transparent solution. After a few minutes of reaction, the solution began to turn light red. With the prolongation of stirring time, the color gradually deepened. After 1.5 hours of reaction, a solution of silver nanoparticles was obtained. The resulting solution was stored protected from light.

Embodiment 3

[0056] The difference between this embodiment and Embodiment 1 is:

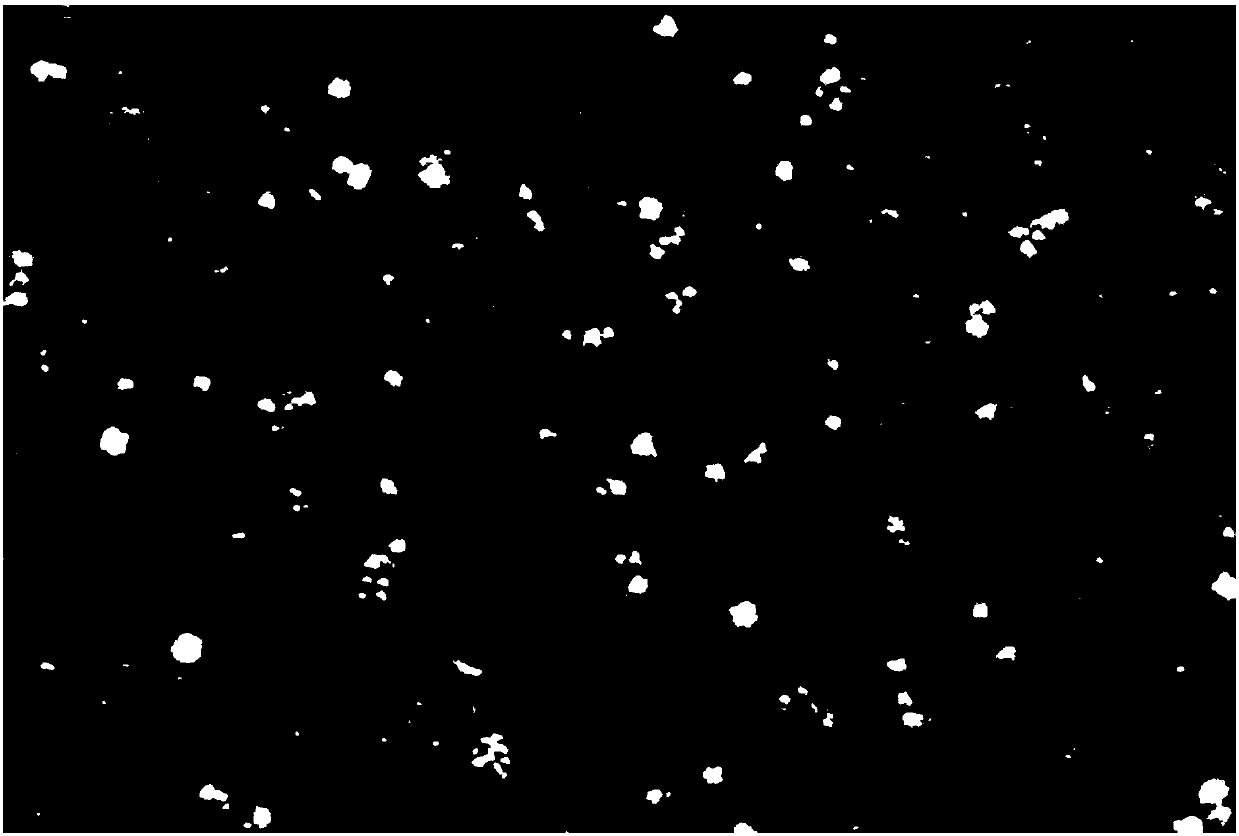

[0057] refer to image 3 Shown is a schematic diagram of the silver nanoparticles obtained in this example.

[0058] Weigh 17.2mg of silver nitrate, then weigh 77.8mg of polyvinylpyrrolidone (Mr ~ 10000), the molar ratio of silver nitrate to polyvinylpyrrolidone is about 1:7, and add them into the reaction vessel at the same time, then add 20ml of water, place in In an environment with natural light, stir the solution well to form a transparent solution. After a few minutes of reaction, a light red transparent solution was formed, and the reaction time was controlled to be 30 minutes to obtain a solution of silver nanoparticles, which was stored away from light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com