A New Turning Method of Cylindrical Internal Gear

A gear car and cylinder technology, applied in the direction of belt/chain/gear, gear teeth, components with teeth, etc., can solve the problem of not being able to bear cutting force, reduce the bearing capacity of gears, life and reliability, internal gear teeth Low manufacturing precision and other problems, to achieve the requirements of reducing machine tool investment, low cost of machine tools and cutting tools, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

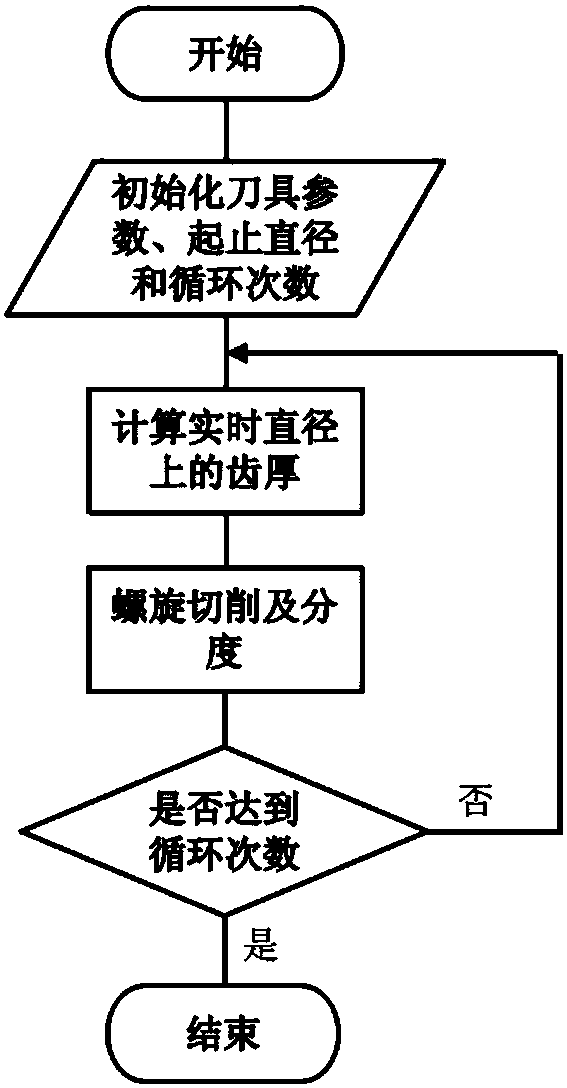

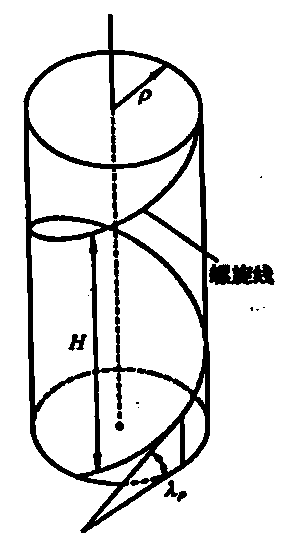

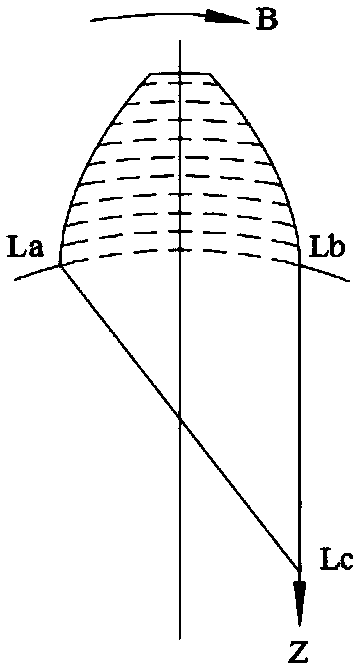

[0021] like Figure 1-2 , a new cylindrical gear turning method, which realizes the machining of involute tooth profile through the principle of plane multi-point NC forming method, which includes circumferential NC forming and radial NC forming. The workpiece axial linear axis Z-axis and the servo spindle B-axis are linked to complete the circular CNC forming action, and at the same time, the material removal in the tooth width direction is completed with a processing principle similar to slotting. The X-axis of the radial axis of the workpiece completes the radial numerical control forming of the plane multi-point numerical control forming method by numerical control. The multi-point compound motion of the Z-axis of the circular NC forming, the B-axis of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com