Method for preparing sodium thiocyanate from ammonia desulphurization waste liquid and sodium carbonate as raw material

A technology for ammonia desulfurization and desulfurization waste liquid, applied in thiocyanic acid and other directions, can solve the problems of low efficiency, pollution and low price of ammonium thiocyanate treatment, and achieve the effects of low cost, simple process and high income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

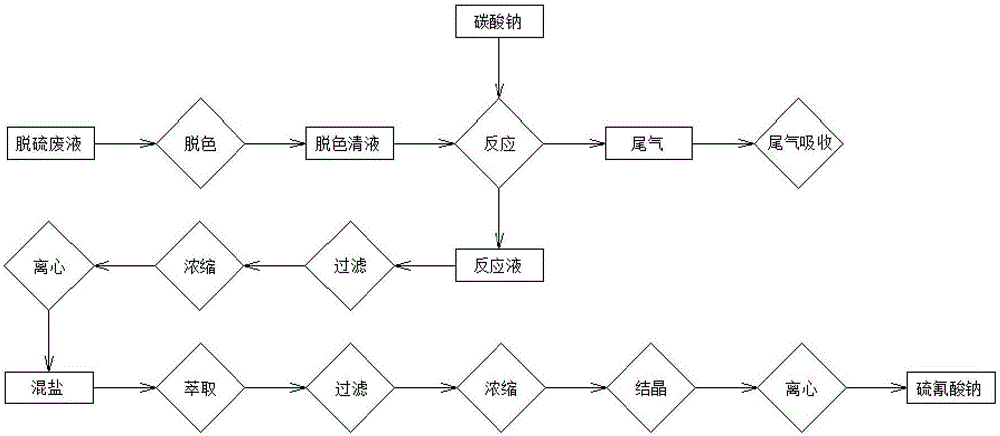

[0025] In this embodiment, sodium thiocyanate is prepared from ammonia desulfurization waste liquid and sodium carbonate, and the overall process route is as follows: figure 1 As shown, the desulfurization waste liquid is first decolorized, the decolorized clear liquid and sodium carbonate are heated and reacted in the reactor, the tail gas is absorbed and treated, the reaction liquid is filtered, concentrated, and centrifuged to obtain mixed salt, and the mixed salt is extracted, filtered, concentrated, and centrifuged. Sodium thiocyanate is obtained.

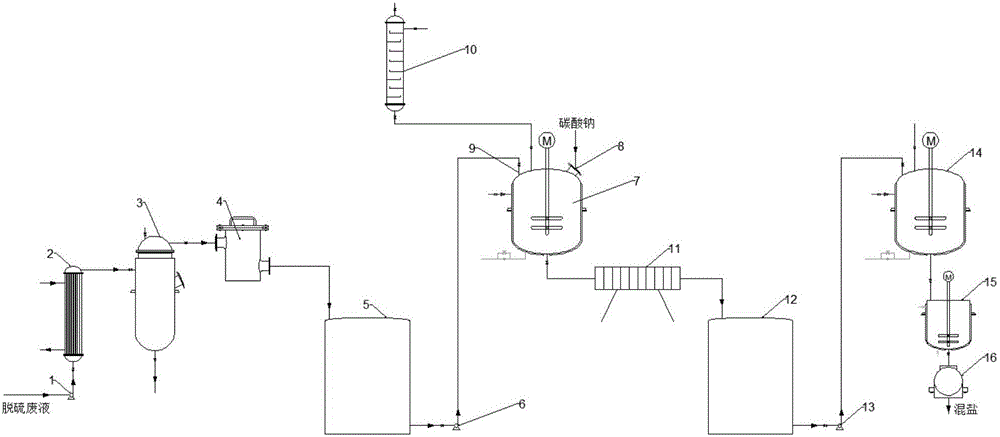

[0026] Specific as figure 2 As shown, the desulfurization waste liquid is pumped into the preheater 2 by the decolorization feeding pump 1 for heat exchange, the temperature is controlled at 85±5°C, and then put into the decolorization tower 3 for decolorization, and then passed through the single cylinder upper and lower basket filter 4 Filter and enter the decolorized clear liquid tank 5; the decolorized clear liquid is pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com