A kind of magnesium phosphate cement with good water resistance and its application method

A magnesium phosphate cement, high-performance technology, applied in the field of building materials, can solve the problem of low overall utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

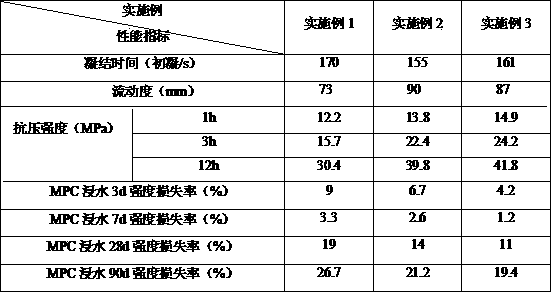

[0042]Embodiment 1, a kind of magnesium phosphate cement with good water resistance performance, according to overburned magnesium oxide 100, potassium dihydrogen phosphate 31.8, coagulation regulator 2, desulfurization gypsum 6.0, fly ash 45, steel slag powder 20, limestone powder 0, reduce The weight ratio of water agent 0.15 and defoamer 0.10 is prepared. According to the water-cement ratio of 0.30, add water and stir evenly before forming. The performance test results are shown in Table 1.

Embodiment 2

[0043] Embodiment 2, a kind of magnesium phosphate cement with good water resistance performance, according to overburned magnesium oxide 100, potassium dihydrogen phosphate 15.8, coagulation regulator 12, desulfurization gypsum 4.0, fly ash 20, steel slag powder 10, limestone powder 8.0, reduce The weight ratio of water agent 0.25 and defoamer 0.30 is prepared. According to the water-cement ratio of 0.30, add water and stir evenly before forming. The performance test results are shown in Table 1.

Embodiment 3

[0044] Embodiment 3, a kind of magnesium phosphate cement with good water resistance performance, according to overburned magnesium oxide 100, potassium dihydrogen phosphate 23.8, coagulation regulator 5, desulfurization gypsum 5.0, fly ash 30, steel slag powder 10.5, limestone powder 7.1, reduce The water agent is 0.22, and the weight ratio of the defoamer is 0.15. According to the water-cement ratio of 0.30, add water and stir evenly before forming. The performance test results are shown in Table 1.

[0045] Table 1 Example performance test results

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com