Method for preparing high-fixed-carbon-content construction material product

A technology for building materials and carbon content, applied in the field of building materials, can solve the problems of low carbon sequestration, low strength, and large emissions in maintenance, and achieve the effects of excellent performance, increased strength, and reduced CO2 emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

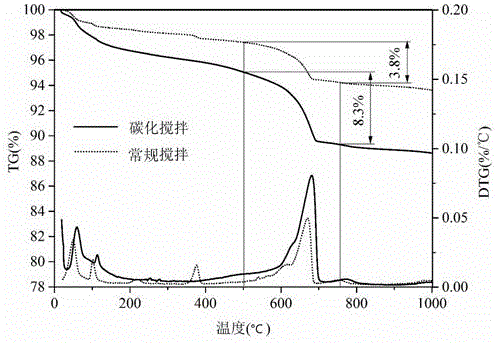

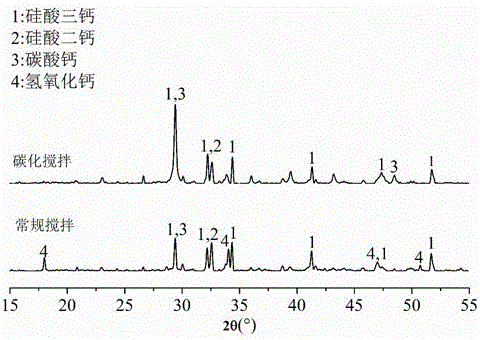

[0034] Select PO 42.5 cement, add water according to the water-cement ratio of 0.15, fully stir in a closed container in a carbon dioxide atmosphere for 1-1.5 minutes, press and shape it into a 40mm×40mm×20mm blank with a pressure of 8MPa, and standardize the obtained blank for 2 Hours, that's it. The carbon dioxide atmosphere is containing CO 2 industrial waste gas or high-purity CO 2 .

Embodiment 2

[0040] Select PO 42.5 cement, add water according to the water-cement ratio of 0.15, and adopt four methods of production, namely: (1) carbonization curing after carbonization stirring, (2) standard curing after carbonization stirring, (3) carbonization curing after conventional stirring , (4) Standard maintenance after conventional stirring. The pressure used for molding is 8MPa, the product size is 40mm×40mm×20mm, and the curing period is 2h.

[0041] The specific operation is as follows:

[0042] (1) Select PO 42.5 cement, add water according to the water-cement ratio of 0.15, fully stir in a closed container in a carbon dioxide atmosphere for 1-1.5 minutes, press and form a blank of 40mm×40mm×20mm with a pressure of 8MPa, and convert the previous step The obtained blank is carbonized and cured for 2 hours under the conditions of a carbon dioxide atmosphere, a curing pressure of 1 bar, and a temperature not lower than 5°C.

[0043] (2) Select PO 42.5 cement, add water acc...

Embodiment 3

[0049] Select P·O42.5 cement, respectively adopt (1) hydration and carbonization stirring for several times and (2) one-time carbonization stirring for stirring, press and form a 40mm×40mm×20mm specimen with a pressure of 8MPa, and carbonize and cure for 2 hours .

[0050] The specific operation is as follows:

[0051] (1) Select PO 42.5 cement, add water according to the water-cement ratio of 0.1, fully stir in a closed container in a carbon dioxide atmosphere for 1-1.5 minutes to obtain a carbonized and stirred mixture; mix the carbonized and stirred mixture obtained in the previous step The ratio of water-cement ratio is 0.15-0.2 for secondary water replenishment, and the mixture is stirred in the air for 1 minute to obtain the mixture stirred for the second time; the weight of ash in the water-cement ratio is the same as that of the gelling material calculate. Use 8MPa pressure to press and form a blank of 40mm×40mm×20mm, and carbonize and cure the blank obtained in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com