Early strength polycarboxylic high performance water-reducing agent and preparation method thereof

A polycarboxylic acid, high-performance technology, applied in the field of concrete admixtures, can solve the problems of complex reaction, high reaction temperature, long reaction time, etc., and achieve the effects of simple operation, convenient preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: a kind of early-strength type polycarboxylate high-performance water reducer, it is made up of the raw material of following weight part:

[0032] Methallyl polyoxyethylene ether: 200; demineralized water: 200; A liquid: 115; B liquid: 86;

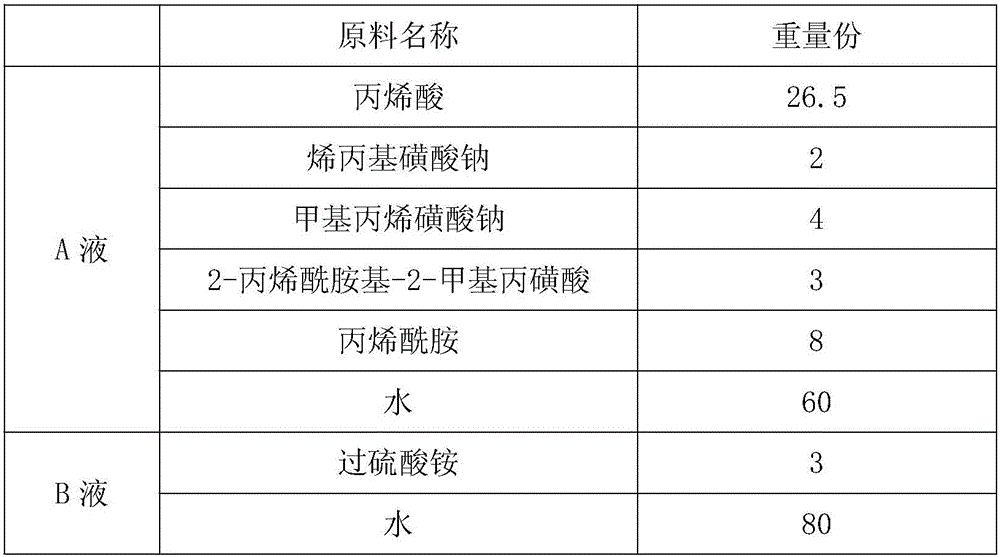

[0033] Wherein, the composition of A liquid and B liquid is as shown in table 1:

[0034] Table 1: Composition of A liquid and B liquid in embodiment 1

[0035]

[0036] The preparation method of the above-mentioned early-strength polycarboxylate high-performance water reducer comprises the following steps;

[0037] S1: Weigh each raw material according to the above weight parts, and prepare A solution and B solution, and set aside;

[0038] S2: Slowly add methallyl polyoxyethylene ether into demineralized water, stir, and continue to stir for 0.5h after the addition, so that methallyl polyoxyethylene ether is fully dissolved, and then formulated to a mass percentage of 55% After heating up to 63°C, add solution ...

Embodiment 2

[0041] Embodiment 2: a kind of early-strength type polycarboxylate high-performance water reducing agent, it is made up of the raw material of following weight part:

[0042] Methallyl polyoxyethylene ether: 400; demineralized water: 300; A liquid: 164; B liquid: 137;

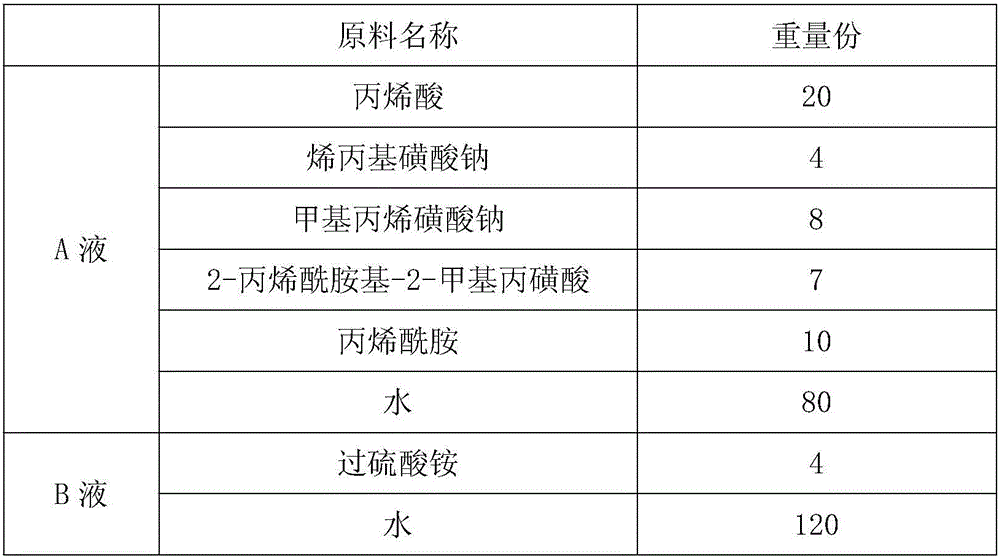

[0043] Wherein, the composition of A liquid and B liquid is as shown in table 2:

[0044] Table 2: Composition of A liquid and B liquid in embodiment 2

[0045]

[0046] The preparation method of the above-mentioned early-strength polycarboxylate high-performance water reducer comprises the following steps;

[0047] S1: Weigh each raw material according to the above weight parts, and prepare A solution and B solution, and set aside;

[0048] S2: Slowly add methallyl polyoxyethylene ether into demineralized water, stir, and continue to stir for 0.5h after the addition, so that methallyl polyoxyethylene ether is fully dissolved, and then formulated to a mass percentage of 60% After heating up to 67°C, add s...

Embodiment 3

[0051] Embodiment 3: a kind of early-strength type polycarboxylate high-performance water reducing agent, it is made up of the raw material of following weight part:

[0052] Methallyl polyoxyethylene ether: 300; demineralized water: 240; A liquid: 121.8; B liquid: 103.6;

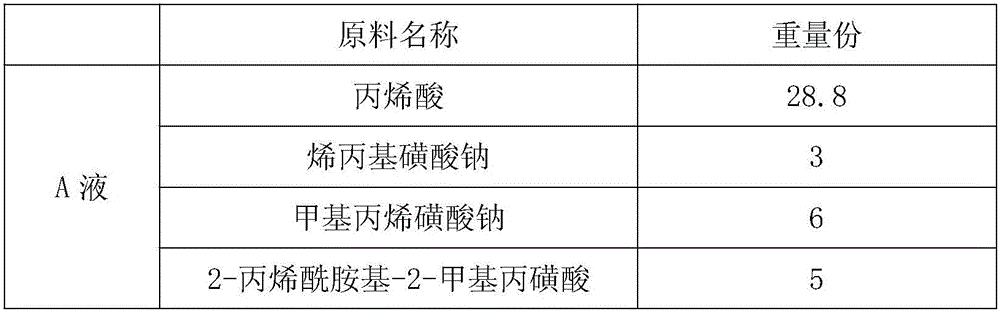

[0053] Wherein, the composition of A liquid and B liquid is as shown in table 3:

[0054] Table 3: Composition of A liquid and B liquid in embodiment 3

[0055]

[0056]

[0057] The preparation method of the above-mentioned early-strength polycarboxylate high-performance water reducer comprises the following steps;

[0058] S1: Weigh each raw material according to the above weight parts, and prepare A solution and B solution, and set aside;

[0059]S2: Slowly add methallyl polyoxyethylene ether to demineralized water, stir, and continue to stir for 0.5h after the addition, so that methallyl polyoxyethylene ether is fully dissolved, and then formulated to a mass percentage of 50% After heating up t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com