A film material for molding

A film material and transparent film technology, applied in polyester coatings, adhesive types, polyurea/polyurethane coatings, etc., can solve the problems of too soft, hardened films are not impact resistant, low stiffness, etc., to achieve soft and effective surface Elastic, not easy to stick to dust, convenient for storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

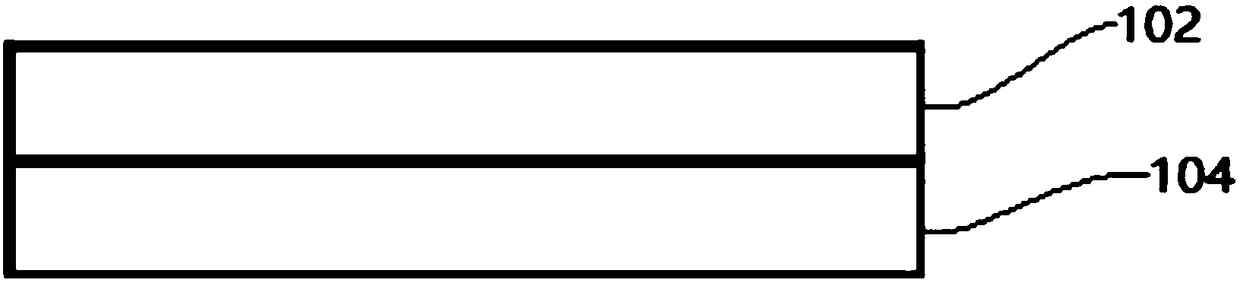

[0021] Such as figure 1 As shown, the transparent film layer 102 of the PET film with a thickness of 0.15mm and a width of 1000mm is coated with an addition molding silicone material as the glue layer 104. The other composition of the glue layer is as follows: 50-60 parts of vinyl silicone rubber, 20 -30 parts of nano silicon dioxide, 10-20 parts of silicone oil, 1-5 parts of conductive ionic liquid, 0.5-2.5 parts of platinum catalyst, 0.5-2.5 parts of hydrogen-containing silicone oil, 1-3 parts of trifluoroacetic acid . The coating thickness is 0.1mm, and the coated PET film undergoes cross-linking and curing reaction at high temperature and then is wound to obtain the final molding film material.

Embodiment 2

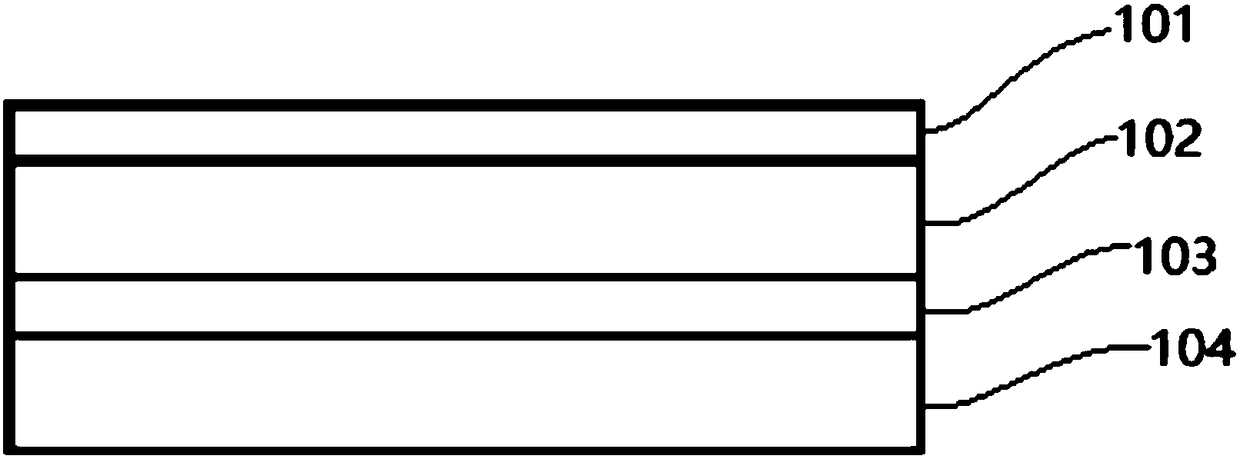

[0023] Such as figure 2 As shown, the transparent film layer 102 of PET film with a thickness of 0.15mm and a width of 1000mm is coated with a water-based polyurethane coating on both sides. The coating thickness is 1μm. This coating can be used as both the ink easy adhesion layer 101 and the adhesive layer Easy-adhesive layer 103, on either side of the PET film with ink and adhesive layer. The easy-adhesive layer is coated with an addition-molded silicone material as the adhesive layer 104. The other composition of the adhesive layer is as follows: 50-60 parts of vinyl silicone rubber, 20 -30 parts of nano silicon dioxide, 10-20 parts of silicone oil, 1-5 parts of conductive ionic liquid, 0.5-2.5 parts of platinum catalyst, 0.5-2.5 parts of hydrogen-containing silicone oil, 1-3 parts of trifluoroacetic acid . The coating thickness is 0.1mm, and the coated PET film undergoes cross-linking and curing reaction at high temperature and then is wound to obtain the final forming fil...

Embodiment 3

[0025] Such as figure 2 As shown, the transparent film layer 102 of PC film with a thickness of 10μm and a width of 1000mm is coated with water-based polyester paint on one side, and the coating thickness is 0.1μm. This coating serves as the ink easy adhesion layer 101, and the other side is coated with modified Organosilicon paint, the thickness of the coating is 0.2μm. This coating is used as the easy-adhesive layer 103, and the side with the easy-adhesive layer is coated with peroxide-initiated organic silicon material as the adhesive layer 104. Other adhesive layers The composition is as follows: 50-60 parts of methyl silicone rubber, 20-30 parts of nano silica, 10-20 parts of silicone oil, 1-5 parts of quaternary ammonium salt, 0.5-2.5 parts of BPO (peroxide Dibenzoyl), 1-3 parts of a mixture of trifluoroacetic acid and titanium dioxide nanoparticles. The coating thickness is 3μm, and the coated PET film is vulcanized at high temperature and then rolled to obtain the fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com