A kind of preparation method of low-grade niobium-titanium iron alloy

A ferroalloy, niobium-titanium technology, applied in the field of ferroalloy smelting, can solve the problems of unfavorable industrialization implementation, difficult operation, high equipment requirements, etc., and achieve the effect of facilitating industrialization implementation, reducing production costs and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

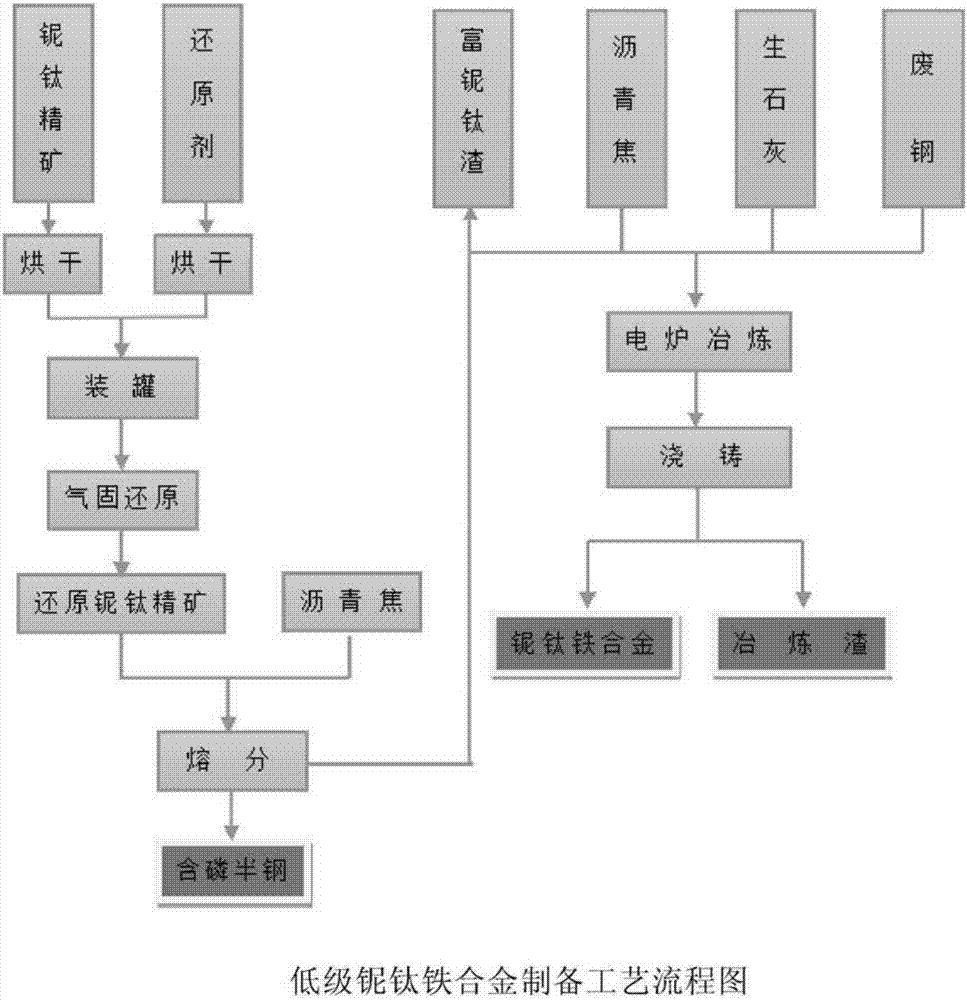

Image

Examples

Embodiment 1

[0069] (1) Gas-solid selective reduction

[0070] a. Weigh 4000kg of niobium-titanium concentrate and 2000kg of coke powder and dry them in a tunnel drying kiln with a moisture content of less than 2%;

[0071] b. Put the niobium-titanium concentrate into the middle ring of the silicon carbide reaction tank, lay a certain thickness of coke powder on the bottom of the tank, fill the inner and outer rings of the tank and all the remaining space with coke powder, and then cover and seal;

[0072] c. Carry out gas-solid selective reduction of the filled tank in a tunnel kiln at a temperature of 1000°C for 35 hours, and cool naturally after the reaction;

[0073] d. A total of 3200kg of reduced niobium-titanium concentrates were produced, with an average composition of Nb 2 o 5 Content 5.98wt%, FeO content 12.8wt%, TFe content 49.68wt%, TiO 2 Content 9.77wt%, SiO 2 The CaO content is 25.9wt%, the CaO content is 1.58wt%, and the F content is 0.99wt%.

[0074] (2) Furnace meltin...

Embodiment 2

[0089] (1) Selective reduction

[0090]a. Weigh 4000kg of niobium-titanium concentrate and 2000kg of coke powder and dry them in a tunnel drying kiln with a moisture content of less than 2%;

[0091] b. Put the niobium-titanium concentrate into the middle ring of the silicon carbide reaction tank, lay a certain thickness of coke powder on the bottom of the tank, fill the inner and outer rings of the tank and all the remaining space with coke powder, and then cover and seal;

[0092] c. Carry out gas-solid selective reduction of the filled tank in a tunnel kiln at a temperature of 1050°C for 30 hours, and cool naturally after the reaction;

[0093] d. A total of 3180kg of reduced niobium-titanium concentrates were produced, with an average composition of Nb 2 o 5 Content 6.1wt%, FeO content 12.67wt%, TFe content 49.54wt%, TiO 2 Content 9.8wt%, SiO 2 The CaO content is 25.7wt%, the CaO content is 1.57wt%, and the F content is 0.97wt%.

[0094] (2) Furnace melting

[0095] ...

Embodiment 3

[0109] (1) Selective reduction

[0110] a. Weigh 4000kg of niobium-titanium concentrate and 2000kg of coke powder and dry them in a tunnel drying kiln with a moisture content of less than 2%;

[0111] b. Put the niobium-titanium concentrate into the middle ring of the silicon carbide reaction tank, lay a certain thickness of coke powder on the bottom of the tank, fill the inner and outer rings of the tank and all the remaining space with coke powder, and then cover and seal;

[0112] c. Carry out gas-solid selective reduction of the filled tank in a tunnel kiln at a temperature of 1150°C for 30 hours, and cool naturally after the reaction;

[0113] d. A total of 3206kg of reduced niobium-titanium concentrates were produced, with an average composition of Nb 2 o 5 Content 6.21wt%, FeO content 12.72wt%, TFe content 49.6wt%, TiO 2 Content 9.82wt%, SiO 2 The CaO content is 25.6wt%, the CaO content is 1.57wt%, and the F content is 0.98wt%.

[0114] (2) Furnace melting

[0115...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com