Optical system for precise control of hollow beam size

A hollow beam and optical system technology, applied in the optical field, can solve the problems of inability to flexibly capture particles, difficult to control and limit the size of the hollow beam, and achieve the effects of simple structure, simple operation and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further explain the technical solution of the system of the present invention, the system of the present invention will be described in detail below through specific examples.

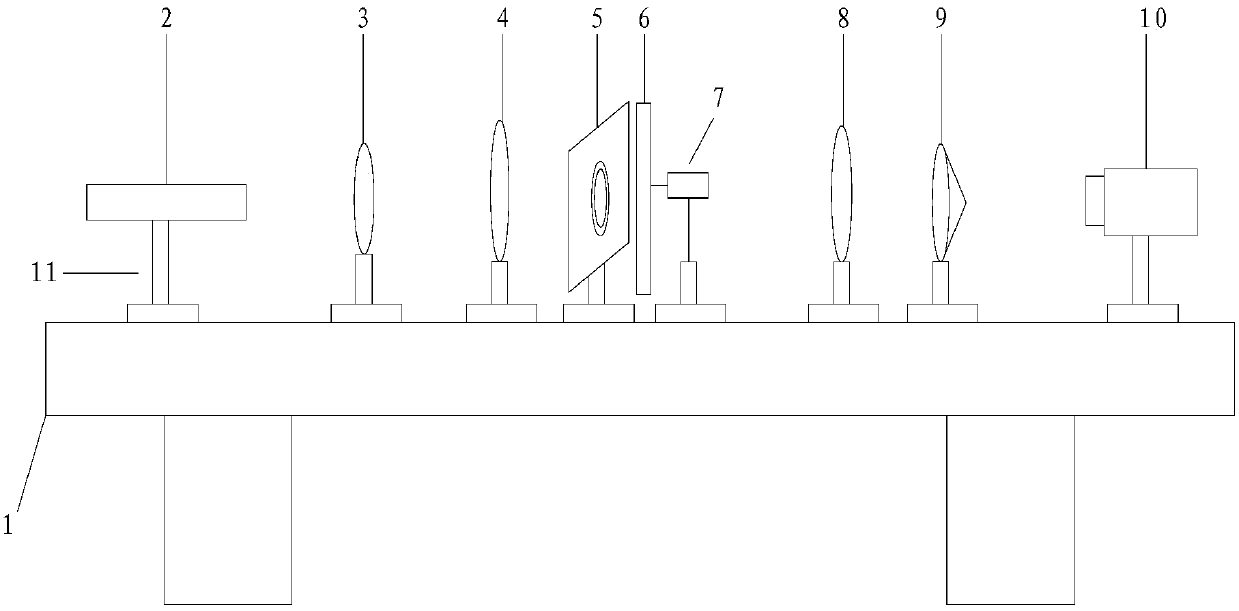

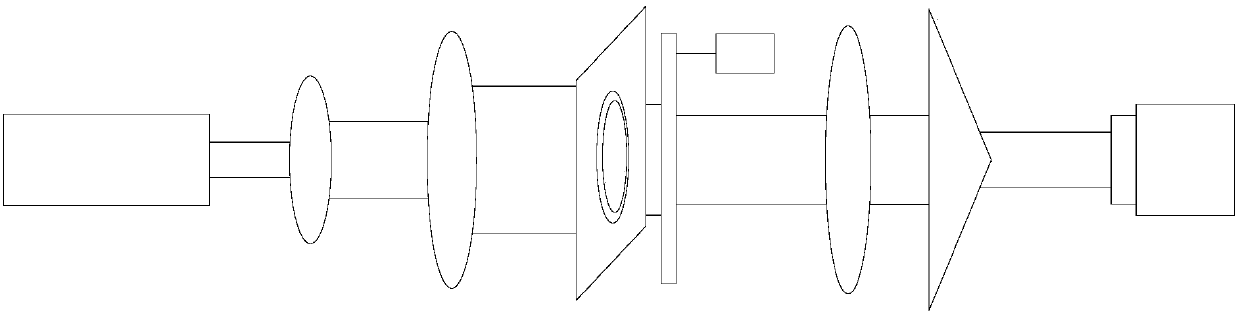

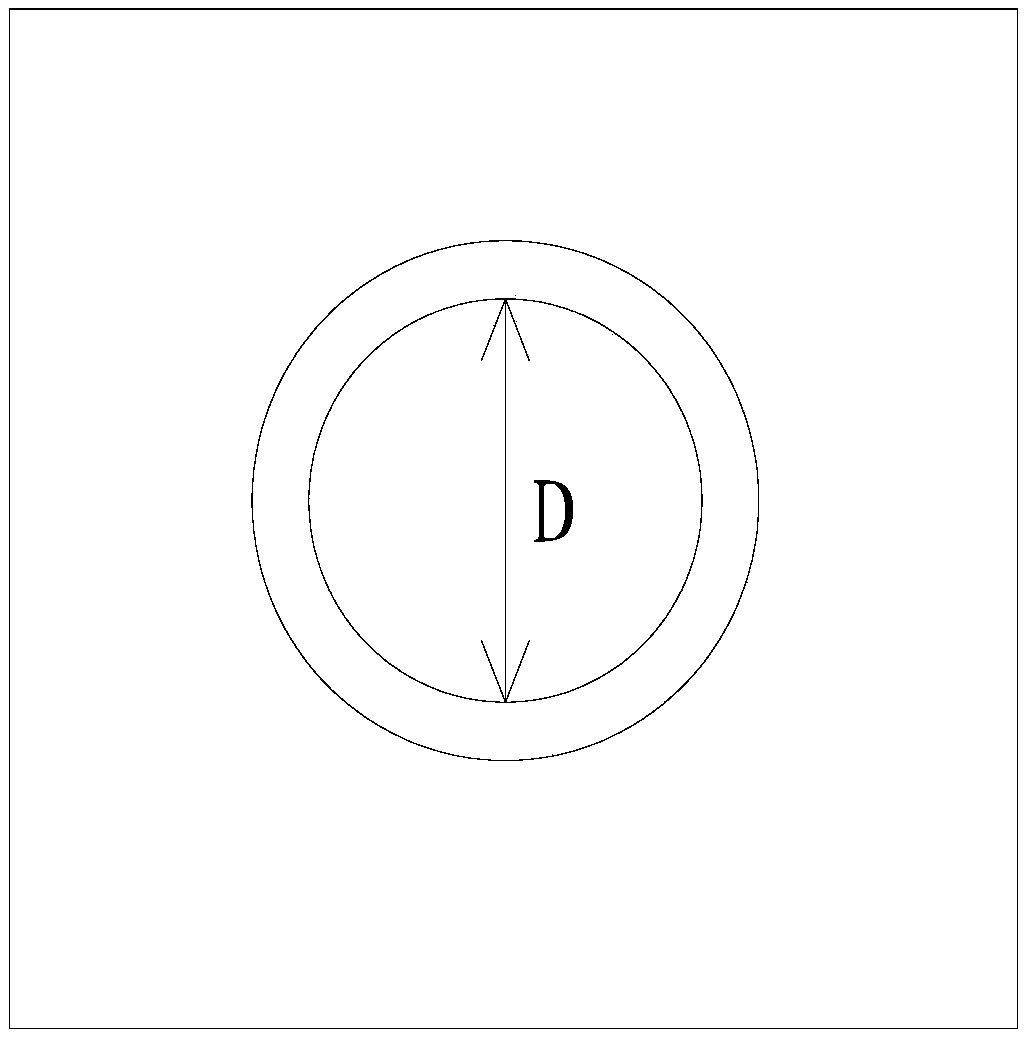

[0013] The optical system for precisely regulating the size of the hollow beam of the present invention, such as figure 1 As shown, it includes an optical table 1, on which a He-Ne laser 2 is arranged, and along the optical path of the He-Ne laser 2, a short focal length lens 3, a long focal length lens 4, an annular seam 5 with adjustable diameter, ground glass 6, Thin lens 8 and axicon 9. A small motor 7 for driving the ground glass 6 to rotate is arranged between the ground glass 6 and the thin lens 8 , and a CCD imaging system 10 for measuring the diameter of the generated hollow beam is arranged behind the axicon 9 .

[0014] The laser 2, the short focal length lens 3, the long focal length lens 4, the circular slit 5 with adjustable diameter, the frosted glass 6, the small mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com