Predictive fuzzy control optimized control method for waste plastic oil refining cracking furnace chamber pressure

A fuzzy control and pressure control technology, applied in the field of automation, can solve the problems of poor control performance, danger, and inability to meet the control accuracy and product quality requirements of coking oven temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Take the furnace pressure process control of waste plastic refining cracking furnace as an example:

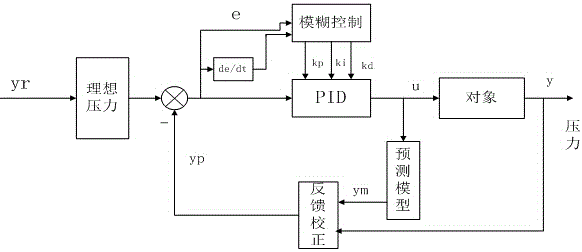

[0053] The furnace pressure of the cracking furnace is an important parameter in the cracking process of the cracking furnace, and the adjustment method adopts the opening of the flue baffle, see figure 1 .

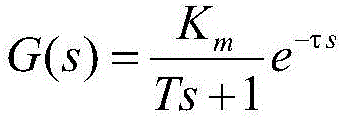

[0054] Step 1. Establish the model of the controlled object through the real-time step response data of the cracking furnace furnace pressure object. The specific method is:

[0055] 1.1 Keep the proportional integral differential controller of the process in the manual operation state, operate the dial to make the output have a step change, record the output value of the actual process of the instrument, and record the actual process output value specifically is:

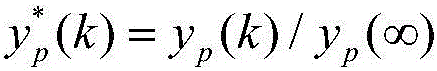

[0056] y p * ( k ) = y p ( k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com