Pixel unit, production method thereof, array substrate and display device

A pixel unit and array substrate technology, applied in the field of technical display, can solve the problems of affecting the display effect, limited light-emitting area, and affecting the light-emitting effect, so as to achieve the effects of improving the light-emitting effect, increasing the light-emitting area, and shortening the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

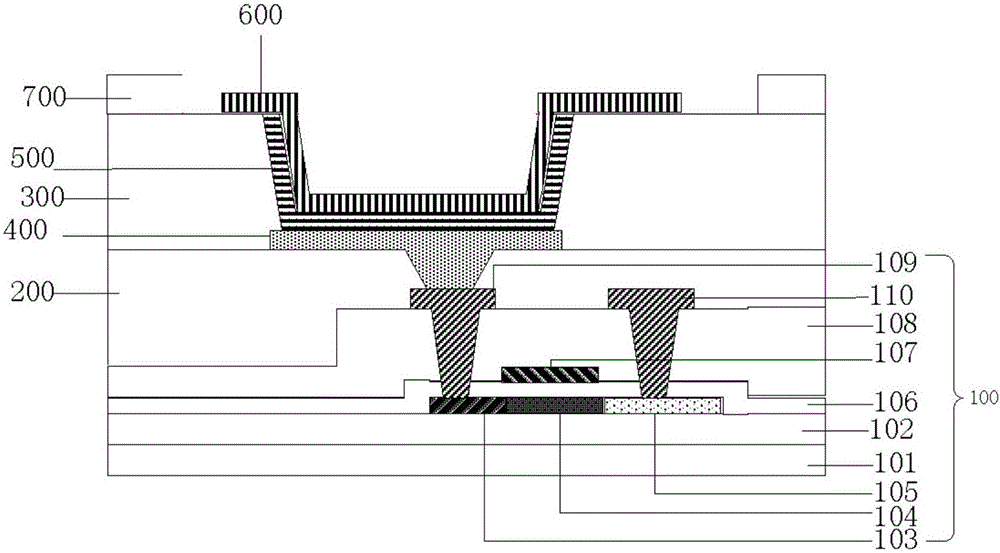

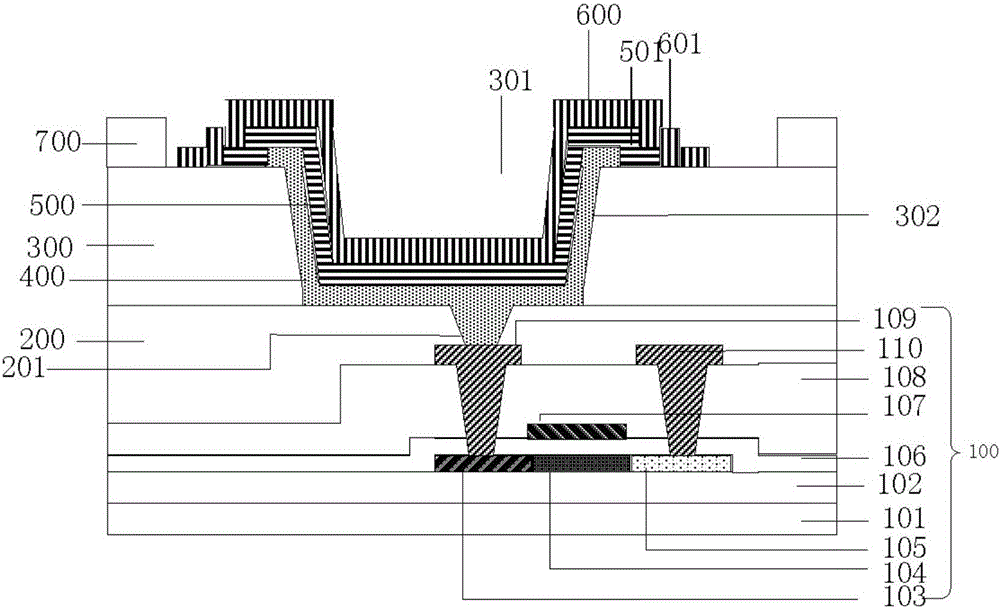

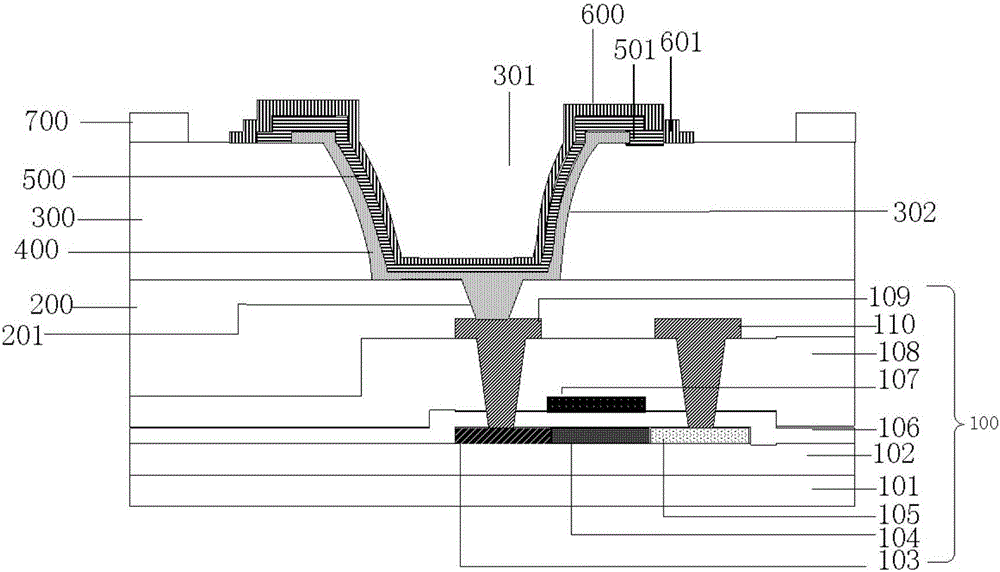

[0045] see figure 2 , figure 2 Shows the pixel unit of the first embodiment of the present invention, the pixel unit is formed on the driving thin film transistor, including: a planarization layer (PLN layer) 200, a pixel definition layer (PDL layer) 300, a pixel electrode 400, a light emitting layer 500 and common electrode 600,

[0046] Wherein, the driving thin film transistor may be a low-temperature polysilicon thin film transistor, including a substrate 101, a buffer layer 101 formed on the substrate 101, an output electrode 103-channel 104-input electrode 105 formed on the buffer layer 101, and an output electrode 103-channel 104-input electrode 105 formed on the buffer layer 101. Layer 102 and the gate insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com