Carbon-fiber indoor air purifier and preparation method thereof

An air purifier and indoor air technology, applied in the direction of chemical instruments and methods, separation methods, heating methods, etc., can solve the problems of urgent, incapable of PM2.5 adsorption, single purification function, etc., to achieve convenient disassembly and replacement, and efficient degradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

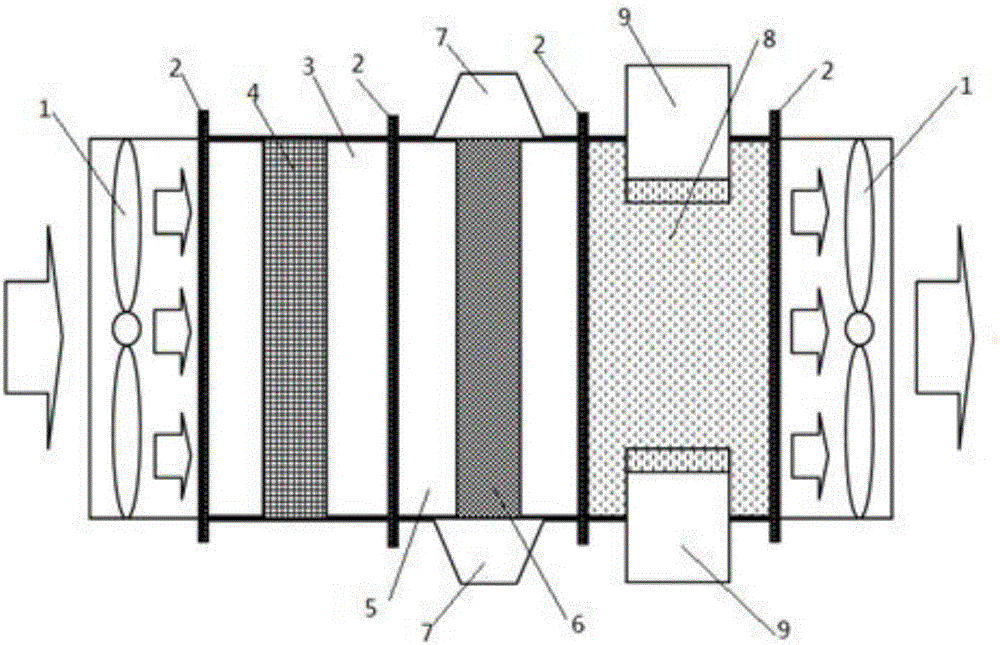

[0040] The carbon fiber indoor air purifier of the present invention includes a three-stage air purification device: a PM2.5 microparticle adsorption device, a formaldehyde photocatalytic degradation device, and an atomized air humidification device. The three-stage purification device is connected into a whole through the slot, and the indoor air driving force is provided by the exhaust fans on both sides to complete the rapid purification of the indoor air.

[0041] First, the preparation of PM2.5 microparticulate matter adsorption device. The non-woven fabric made of polyethylene fiber is prepared with a thickness of 0.1mm, 50 meshes, and an areal density of 10g / m 2 The surface filter layer is made of high-strength T300 carbon fiber and the specific surface area is 300m after high temperature activation. 2 / g of activated carbon fiber filament, the activated carbon fiber is woven into a non-woven structure microparticle pollutant adsorption layer, and the fabric surface density...

Embodiment 2

[0048] The carbon fiber indoor air purifier of the present invention includes a three-stage air purification device: a PM2.5 microparticle adsorption device, a formaldehyde photocatalytic degradation device, and an atomized air humidification device. The three-stage purification device is connected into a whole through the slot, and the indoor air driving force is provided by the exhaust fans on both sides to complete the rapid purification of the indoor air.

[0049] First, the preparation of PM2.5 microparticulate matter adsorption device. The mesh fabric woven fabric of polypropylene fiber is prepared with a thickness of 0.5mm, 200 meshes, and an areal density of 200g / m 2 The surface filter layer is made of high-strength T700 carbon fiber and the specific surface area is 1000m after high temperature activation. 2 / g of activated carbon fiber filaments, the activated carbon fiber is woven into a plain weave structure micro-particle pollutant adsorption layer, the fabric surface ...

Embodiment 3

[0059] The carbon fiber indoor air purifier of the present invention includes a three-stage air purification device: a PM2.5 microparticle adsorption device, a formaldehyde photocatalytic degradation device, and an atomized air humidification device. The three-stage purification device is connected into a whole through the slot, and the indoor air driving force is provided by the exhaust fans on both sides to complete the rapid purification of the indoor air.

[0060] First, the preparation of PM2.5 microparticulate matter adsorption device. The satin weave fabric made of polyester fiber has a thickness of 0.8mm, 130 meshes, and an areal density of 120g / m 2 The surface filter layer is made of high-strength T800 carbon fiber through high temperature activation and the specific surface area is 1300m 2 / g activated carbon fiber filament, the activated carbon fiber is woven into a mesh cloth structure micro-particle pollutant adsorption layer, the fabric surface density of the prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com