Product detection method based on machine vision

A detection method and machine vision technology, which is applied in the field of control of mechanical arm grasping and machine vision detection, can solve the problems of poor applicability and low product detection accuracy, and achieve the effects of applicability, high precision and improved detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

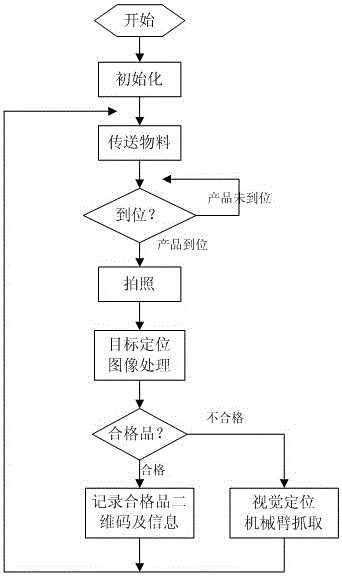

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

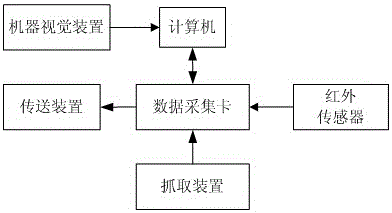

[0050] figure 1It is the overall structure diagram of the system of the present invention. The system mainly includes a computer, a data acquisition card (ELVISII), a machine vision device, a transmission device, a grabbing device and an infrared photoelectric sensor (E18-D80NK). The computer is the core of the whole system. Through the pre-installed LabVIEW software, NI-DAQ device driver and NIVisionDevelopmentsModule (VDM) vision development kit, the programming control of conveying devices, machine vision devices and other devices can be realized.

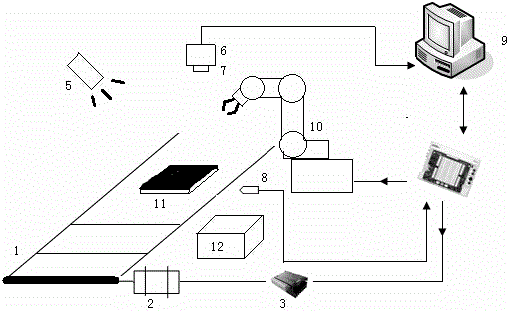

[0051] figure 2 It is an overall schematic diagram of the system of the present invention, in which the machine vision device includes a light source, an industrial camera (Basler, acA1300-30um), a lens (ComputarM0814-MP) and an infrared photoelectric sensor. The transmission device includes a conveyor belt,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com