Method, processing system and collecting system for processing various structure colors through femtosecond laser

A femtosecond laser processing and processing system technology, applied in the field of micro-processing, can solve the problems of low direct processing efficiency, hindering the industrialization of structural color, and lack of database for structural color processing, and achieve the effect of meeting various industrial needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

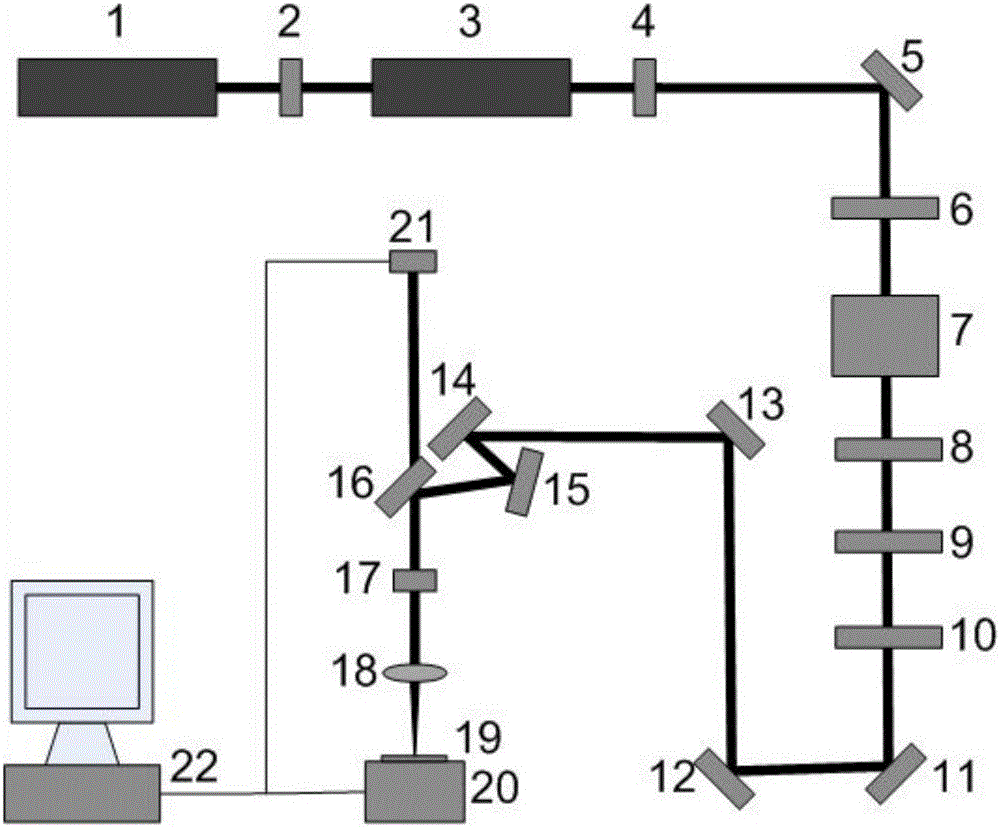

[0037] The multi-color laser micro-nano structure processing system includes laser light source 1, first and second apertures 2 and 4, optical parameter amplifier 3, first, second, third, fourth and fifth mirrors 5, 11, 12, 13, 14. Half wave plate 6, prism 7, 1 / 4 wave plate 8, shutter 9, beam quality analyzer 10, phase plate 15, half mirror 16, energy meter 17, focusing mirror 18, mobile platform 20, CCD camera 21, computer 22, such as figure 1 shown. Among them, the optical parametric amplifier is used to modulate the beam with a center wavelength of 800nm to form a beam of 260-2600nm; 1 / 2 glass and prism are used to control the energy and polarization state of the beam; 1 / 4 glass is used to convert the linearly polarized beam Modulated into circularly polarized light or elliptically polarized light; the phase plate is used to focus the laser beam into a linear focus; the precision mobile platform is used to position and move the sample; the CCD camera is used to monitor t...

Embodiment 2

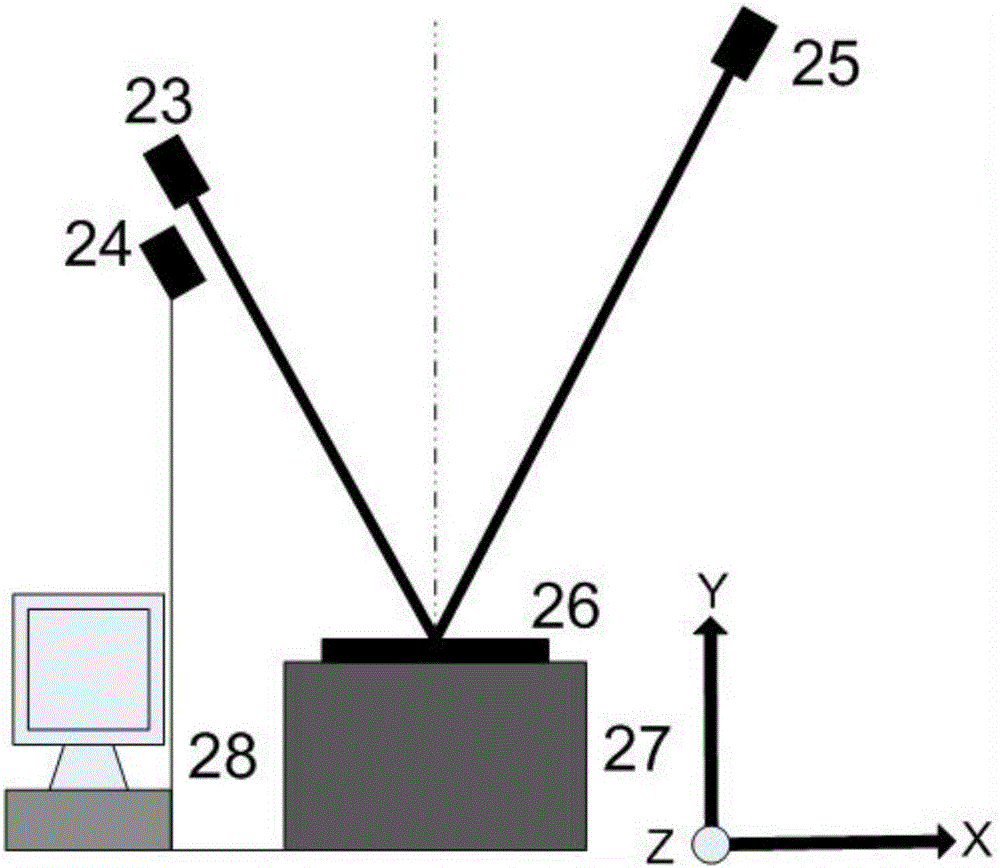

[0039] Using Example 1 to prepare micro-nano structures of various colors on different materials, a collection system for various structural colors is established. The system is mainly composed of an optical camera 23 , a spectrometer 24 , an illumination source 25 , a rotating platform 27 and a computer 28 . The illuminating light source 23 illuminates the sample 26 placed on the rotating platform 27 . The structural color produced by the diffraction and reflection of micro-nano structures on the sample surface is recorded by the optical camera 23 and the spectrometer 24 . By changing the angle between the optical camera 23, the spectrometer 24, the illumination source 25, the rotating platform 27 and the Z-axis in the coordinate system within the range of 0-180° to determine the change of the structural color spectrum, thereby establishing a structural color collection system ( image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com