Polyurethane wall tiles and preparation method thereof

A technology of wall tiles and polyurethane, applied in the field of building materials, can solve the problems of easy dyeing, water absorption, brittleness, etc., and achieve the effects of simple molding process, guarantee of quality of life, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides a kind of preparation method of polyurethane wall tile, and this preparation method uses the composition material of polyurethane wall tile of the present invention as raw material, comprises:

[0034] Mix 100 parts of polyether polyol, 2 to 5 parts of crosslinking agent, 1 to 2 parts of amine catalyst, 3 to 5 parts of stabilizer, 30 to 50 parts of flame retardant and 10 to 30 parts of blowing agent to obtain Group A Minute;

[0035] Add component A and polyisocyanate to a high-pressure injection molding machine in a weight ratio of 10:12 to 10:15 to obtain a mixed material, and the temperature of the mixed material is 20 to 40 degrees Celsius;

[0036] The mixed material is poured into a mold, and the mixed material is solidified and formed by one-step foaming to obtain a polyurethane wall tile. The temperature in the mold is 30 to 60 degrees Celsius.

[0037] Concretely, in practical application, in order to make the appearance of the p...

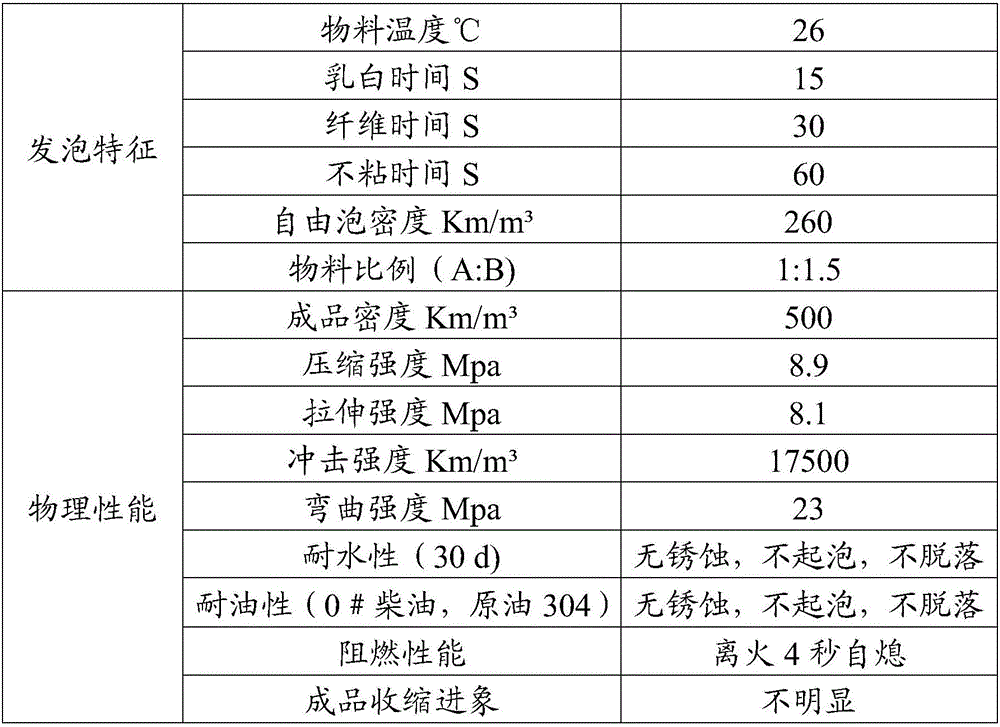

Embodiment 1

[0043] In this embodiment, the polyurethane wall tile can include component A and component B, in parts by weight, component A is 10 parts, and component B is 15 parts;

[0044] Among them, component A may include 70 parts by weight of polyether polyol GR-635C, 30 parts of polyether polyol GE-210, 5 parts of 1,4-butanediol, 2 parts of triethylene Diamine catalyst, 5 parts of organosilicon surfactant, 50 parts of dimethyl methylphosphonate and 10 parts of dichloro-fluoroethane;

[0045] The B component may be a polyisocyanate.

[0046] Using the above-mentioned component materials in parts by weight as raw materials, the specific preparation method can be as follows:

[0047] After the polyether polyol GR-635C and polyether polyol GE-210 are mixed evenly, mix the uniformly mixed polyether polyol, crosslinking agent, amine catalyst, stabilizer, flame retardant and blowing agent to obtain A components;

[0048] Add component A and polyisocyanate to a high-pressure injection mo...

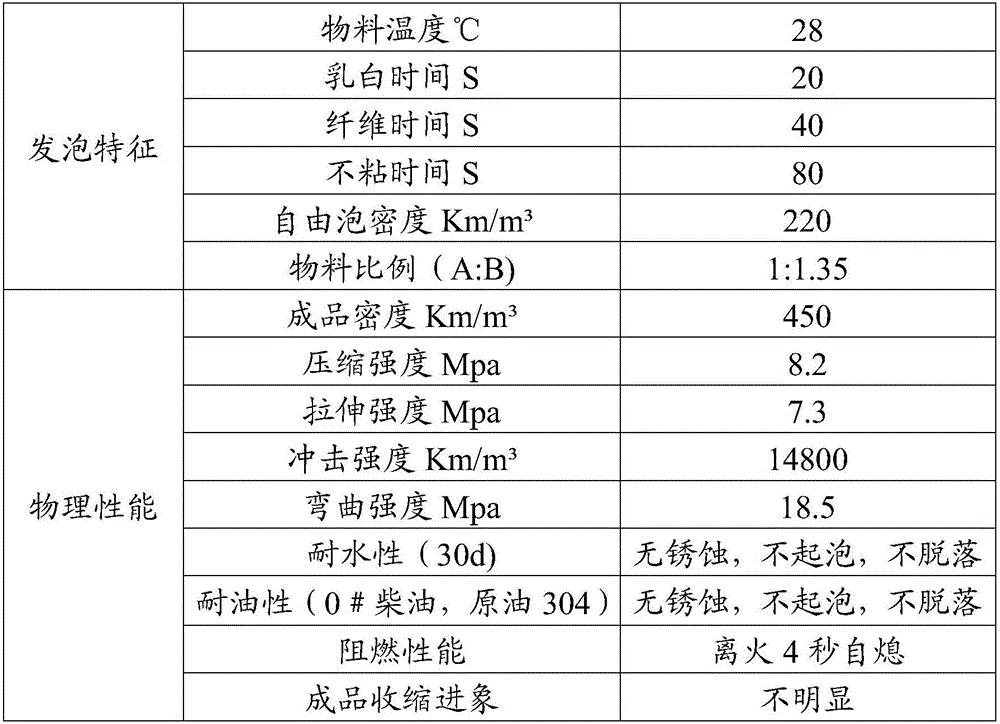

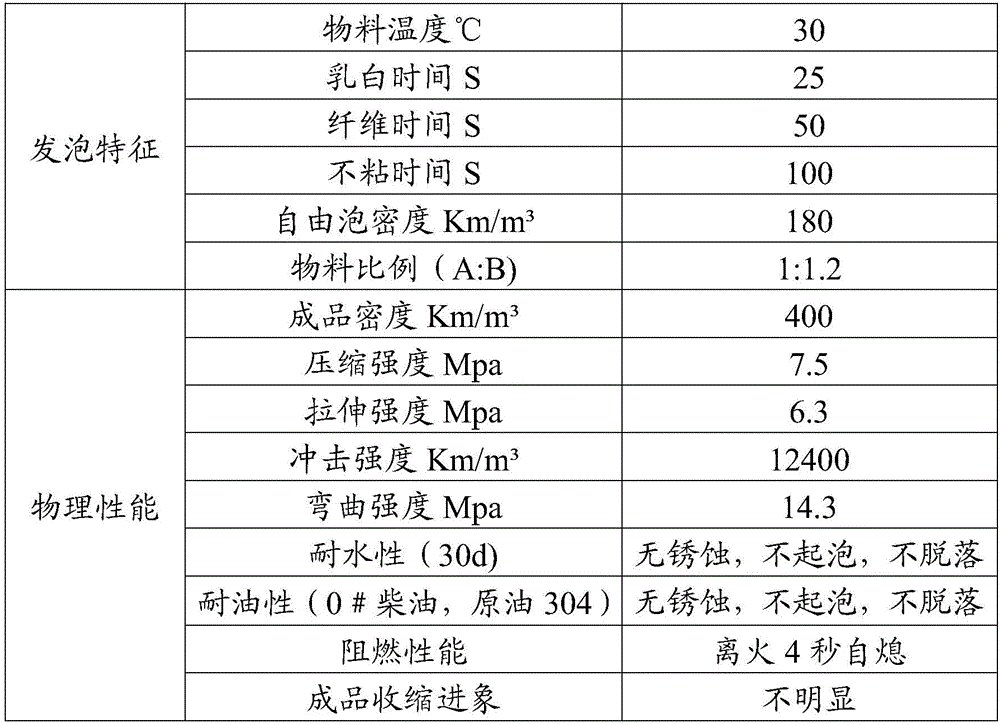

Embodiment 2

[0056] In the present embodiment, the polyurethane wall tile may include component A and component B, in parts by weight, component A is 10 parts, and component B is 13.5 parts;

[0057] Among them, component A can include 65 parts of polyether polyol GR-635C, 35 parts of polyether polyol GE-210, 3.5 parts of 1,4-butanediol, 1.5 parts of triethylene Diamine type catalyst, 4 parts of silicone surfactants, 40 parts of dimethyl methylphosphonate and 20 parts of dichlorofluoroethane;

[0058] The B component may be a polyisocyanate.

[0059] The preparation method of polyurethane wall tiles in this example is the same as the preparation method of polyurethane wall tiles in Example 1 except that the parts by weight of each component are different, and will not be repeated here.

[0060] Further, in order to understand the performance of the polyurethane wall tile in this embodiment, a performance test can be performed on the polyurethane wall tile, and the specific test results ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com