Decoupling film rigidity-variable semi-active suspension

A technology of semi-active suspension and decoupling membrane, which is applied in the direction of power plant, jet propulsion device, internal combustion propulsion device, etc. It can solve the problems of difficulty in mass production, high price, and small controllable range of damping, so as to solve the problems of stiffness and Damping requirements, reducing high-frequency dynamic hardening, and improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the present invention will be described in detail below with reference to the accompanying drawings and in combination with the embodiments.

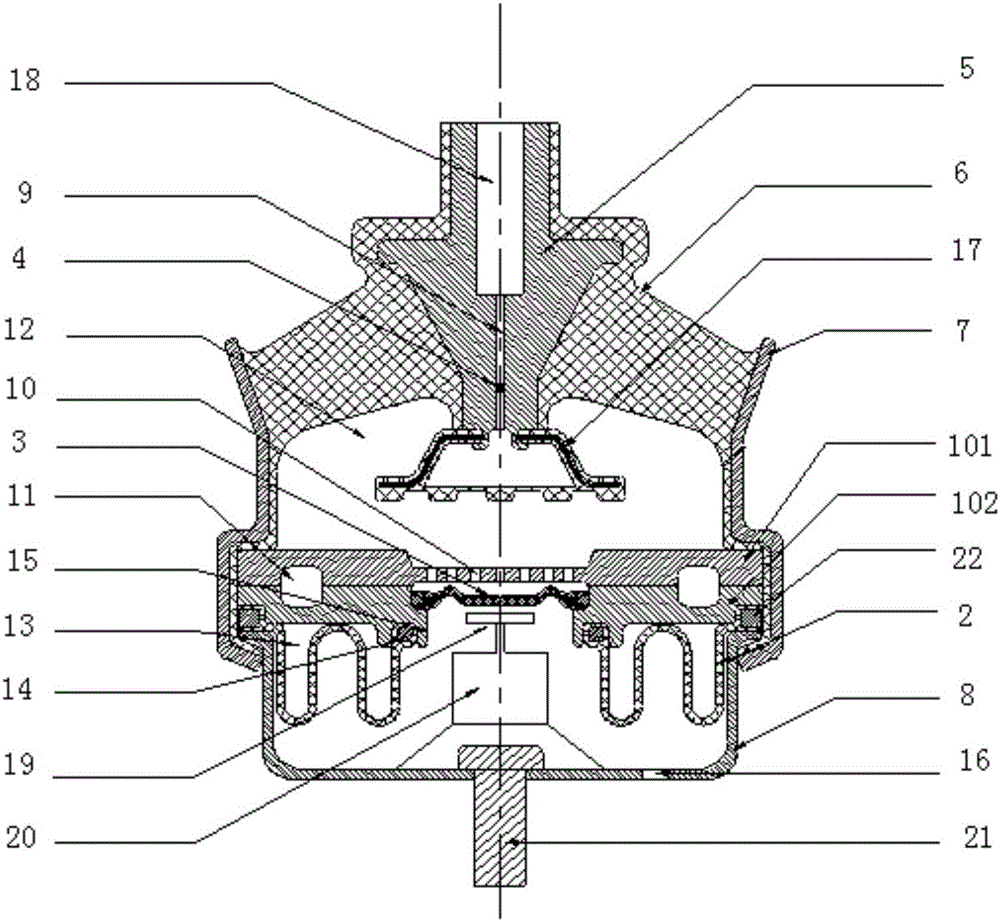

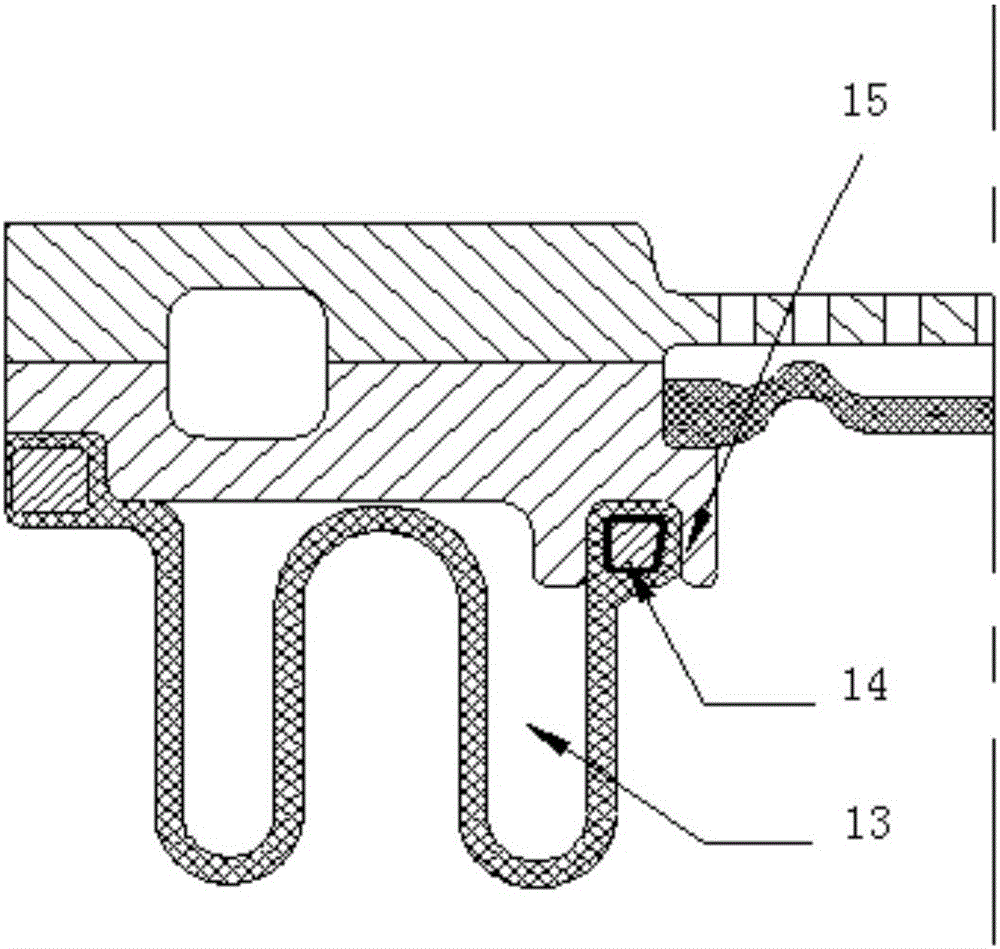

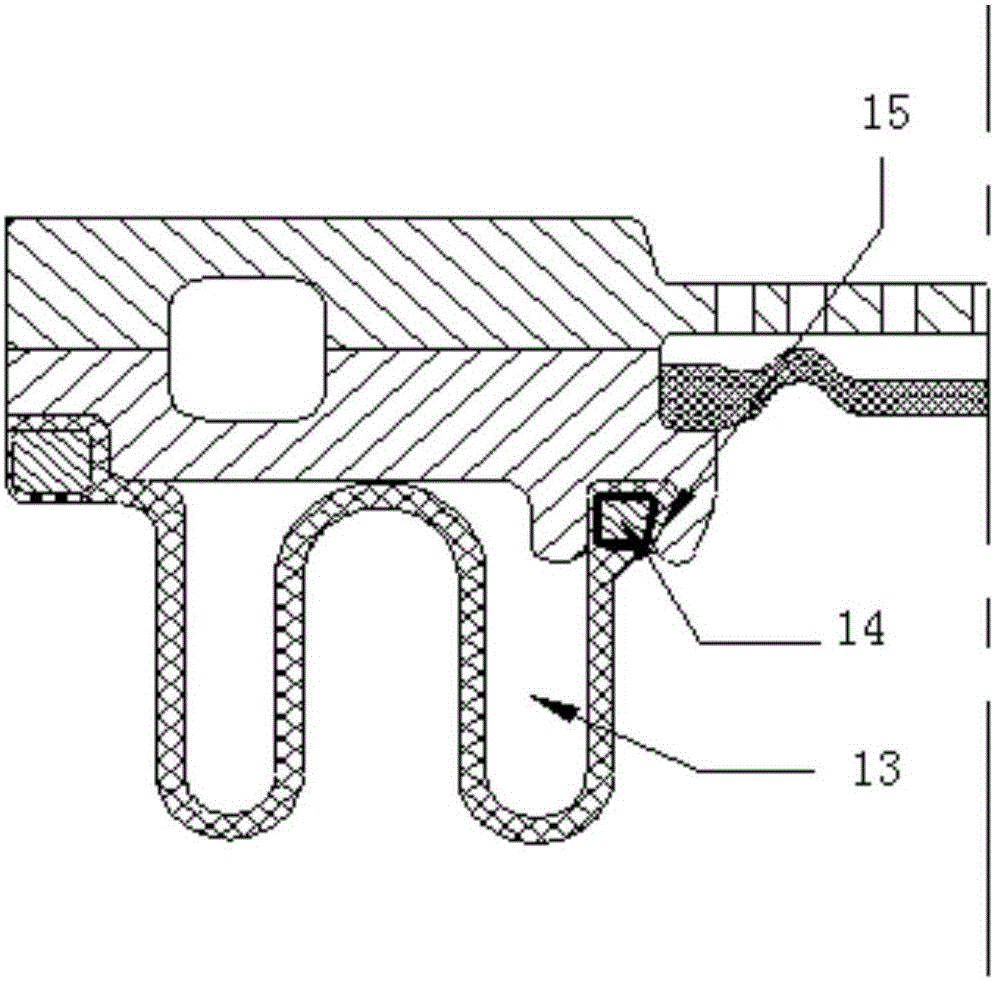

[0026] refer to figure 1 , 2 , 3:

[0027] A decoupling membrane rigidity variable semi-active mount proposed by the present invention includes a housing assembly, a flow channel assembly, a leather cup 2, a decoupling membrane 3, a seal 4, a driving mechanism, and a spoiler 17;

[0028] The housing assembly includes an inner core 5, a rubber main spring 6, an outer frame 7, and a base 8. The inner core 5 is provided with a mounting hole 18 and a liquid inlet hole 9; the first end of the liquid inlet hole 9 is connected to the mounting hole 18 , the second end of the liquid inlet hole 9 is connected with the upper liquid chamber 12; the mounting hole 18 can be a thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com