Pattern plating method for integrating two types of sheet resistance film circuits on same plane of dielectric substrate

A dielectric substrate and graphic electroplating technology, which is applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of metal plating points on the resistance layer and low graphic accuracy, and reduce the risk of scratching conductor graphics and graphic resolution. High and improve the effect of circuit yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

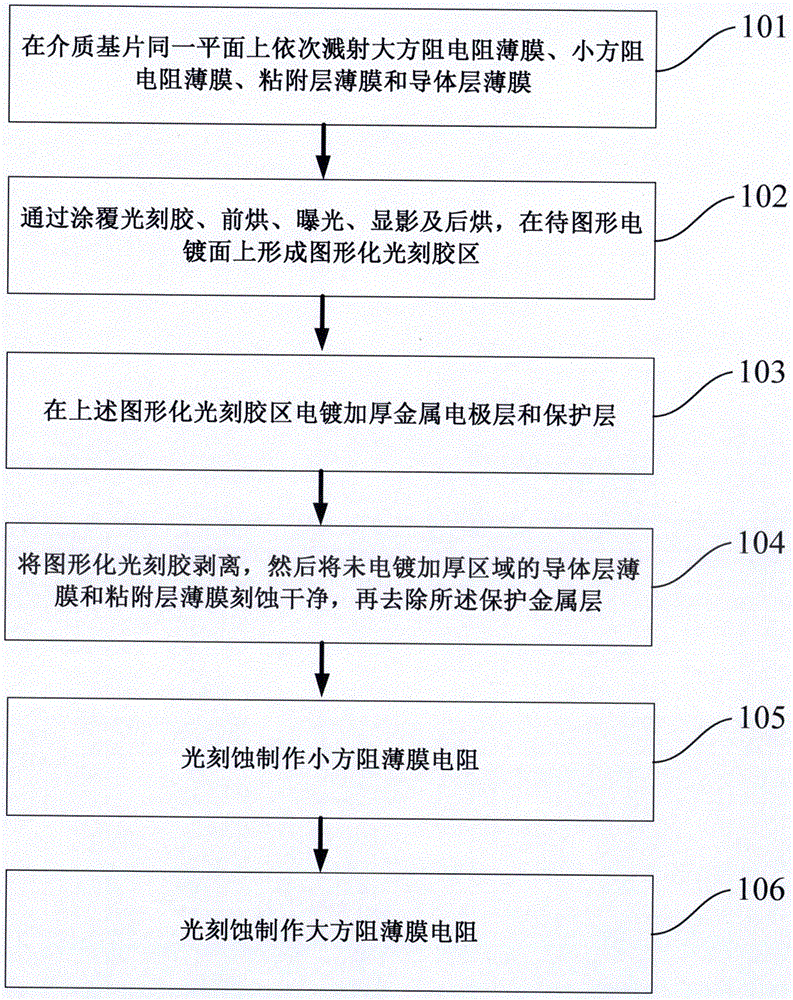

[0036] The NiCr / TaN / TiW / Au films are sequentially deposited on the same plane of the alumina dielectric substrate, taking the electroplating of thin film circuit patterns with two different square resistances of TaN and NiCr as an example:

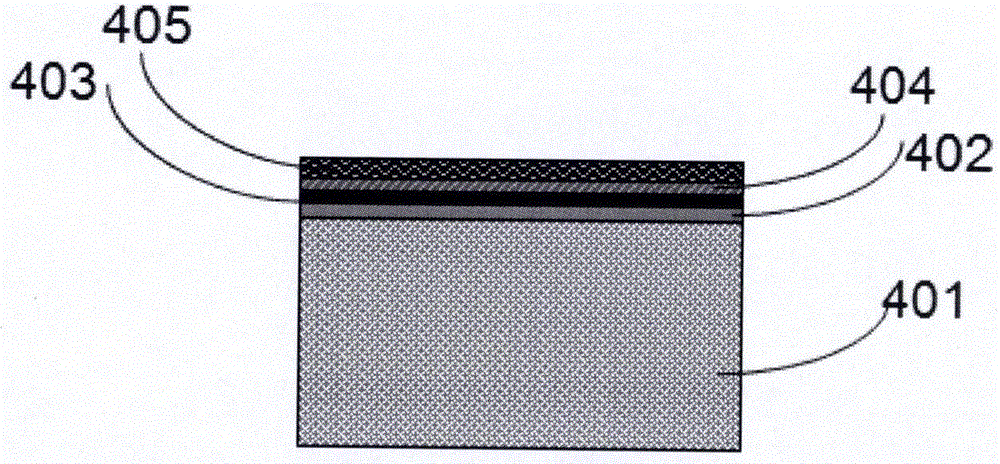

[0037] First, a dielectric substrate 401 is provided, such as Figure 3a As shown, the dielectric material is a 2in×2in square aluminum oxide substrate with a purity of 99.6%-100%, a thickness of 0.254mm, single-sided polishing, and a roughness of ≤1μin. After the dielectric substrate 401 is cleaned, NiCr / TaN / TiW / Au thin films are sequentially sputtered on the polished surface using a magnetron sputtering process. Among them, the large resistance film material 402 is a 200Ω / NiCr film, the small resistance film material 403 is a 9.5Ω / TaN film, the adhesive layer film material 404 is a TiW film, and the conductive layer film material 405 is an Au film.

[0038] Next, the electrode pattern is made into a photolithographic first mask. A laye...

Embodiment 2

[0044] NiCr / Ta / Ti / Au films are sequentially deposited on the same plane of the sapphire dielectric substrate, taking the electroplating of thin film circuit patterns with two different resistances of Ta and NiCr as an example:

[0045] First, a dielectric substrate 401 is provided, such as Figure 3a As shown, the dielectric material is a circular sapphire substrate with a diameter of 2in, a thickness of 0.254mm, double-sided polishing, and a roughness of ≤1μin. After the dielectric substrate 401 is cleaned, NiCr / Ta / Ti / Au thin films are sequentially sputtered on the polished surface using a magnetron sputtering process. Among them, the large resistance film material 402 is a 250Ω / NiCr film, the small resistance film material 403 is a 10Ω / Ta film, the adhesive layer film material 404 is a Ti film, and the conductor layer film material 405 is an Au film.

[0046] Next, the electrode pattern is made into a photolithographic first mask. Spin-coat a layer of RZJ-390PG photoresist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com