Method utilizing microbial fuel cell to process perchlorate

A fuel cell and perchlorate technology, applied in biochemical fuel cells, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of metal surface pollution and low efficiency of perchlorate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

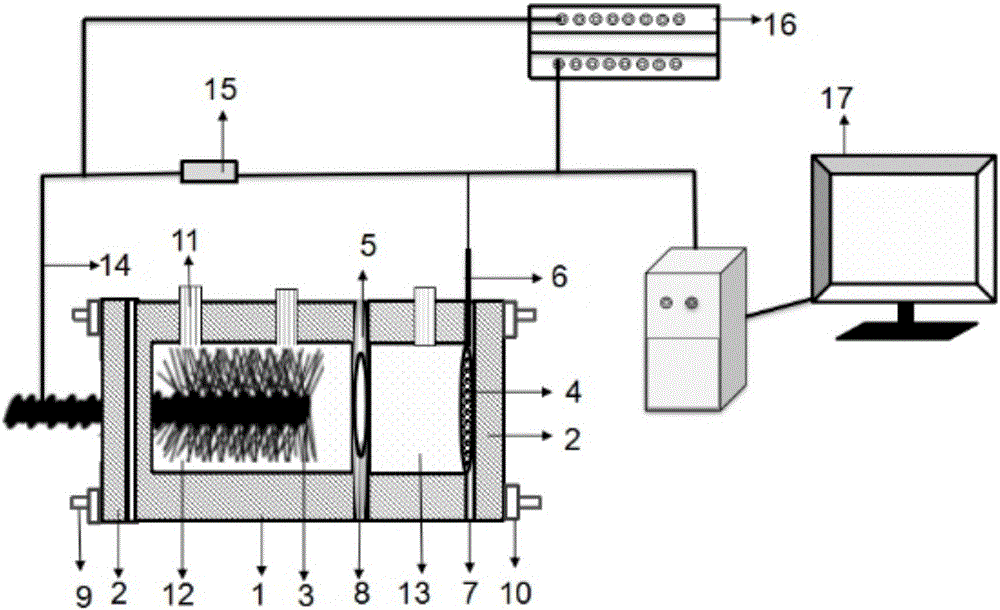

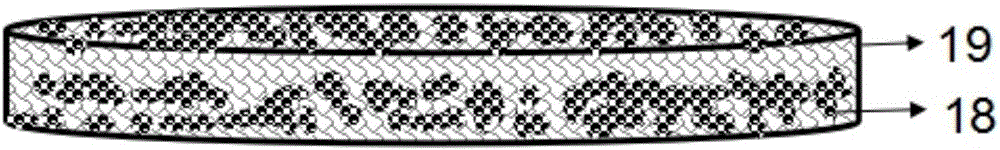

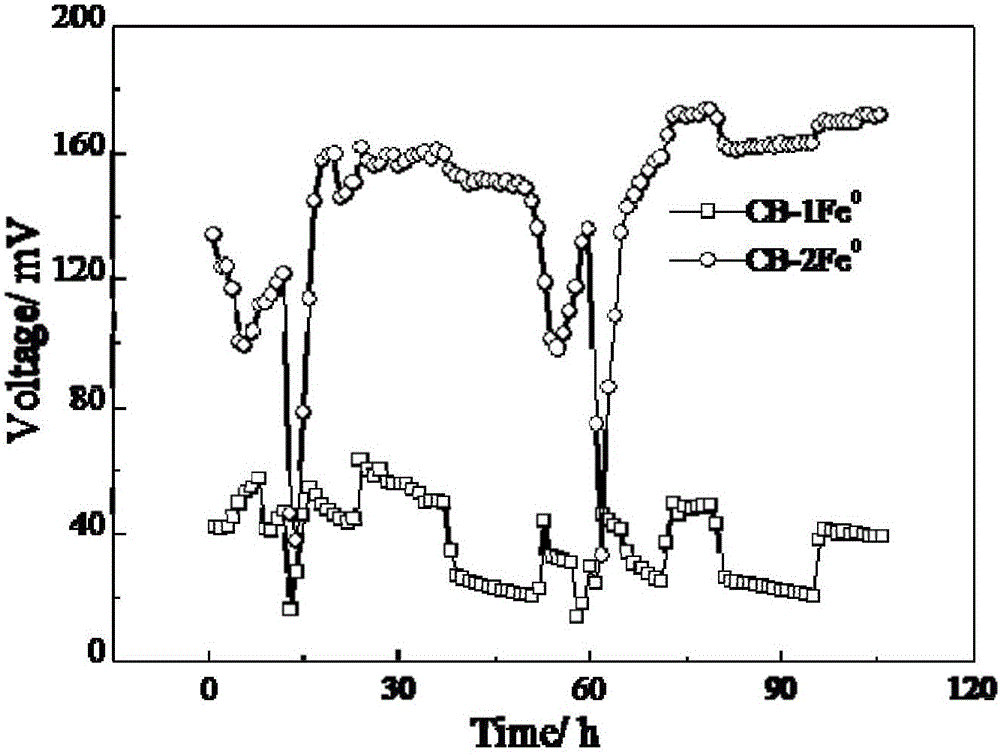

[0024] A device based on a method for treating perchlorate with a microbial fuel cell includes a microbial fuel cell and an external circuit system. The reactor housing 1 of the microbial fuel cell is a plexiglass box, and the upper part of the housing is provided with water inlet and outlet holes. The two reactor shells 1 are connected by a proton exchange membrane 5 and an apron 8 to form an anode chamber 12 and a cathode chamber 13. There is an organic glass plate 2 on the left side of the anode chamber 12, and an organic glass plate 2 on the right side of the cathode chamber 13. The carbon brush anode 3 is inserted in the center position of the plexiglass plate 2, and the brush head is in the anode chamber 12 on the left side, and anaerobic electricity-producing microorganisms are attached on the bristles, and a conductive cathode 4 is embedded in the cathode chamber 13, and Fe is loaded on the cathode 0 The particles 18 and the conductive cathode 4 can be made of carbon cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com