A kind of processing method of strengthening magnesium alloy

A processing method and magnesium alloy technology, applied in the field of magnesium alloy processing, can solve the problems of changing the mechanical properties and formability of magnesium alloys, reducing the temperature of magnesium alloy sheets, and losing heat, so as to facilitate recovery and recrystallization and improve the structure status, effect of avoiding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

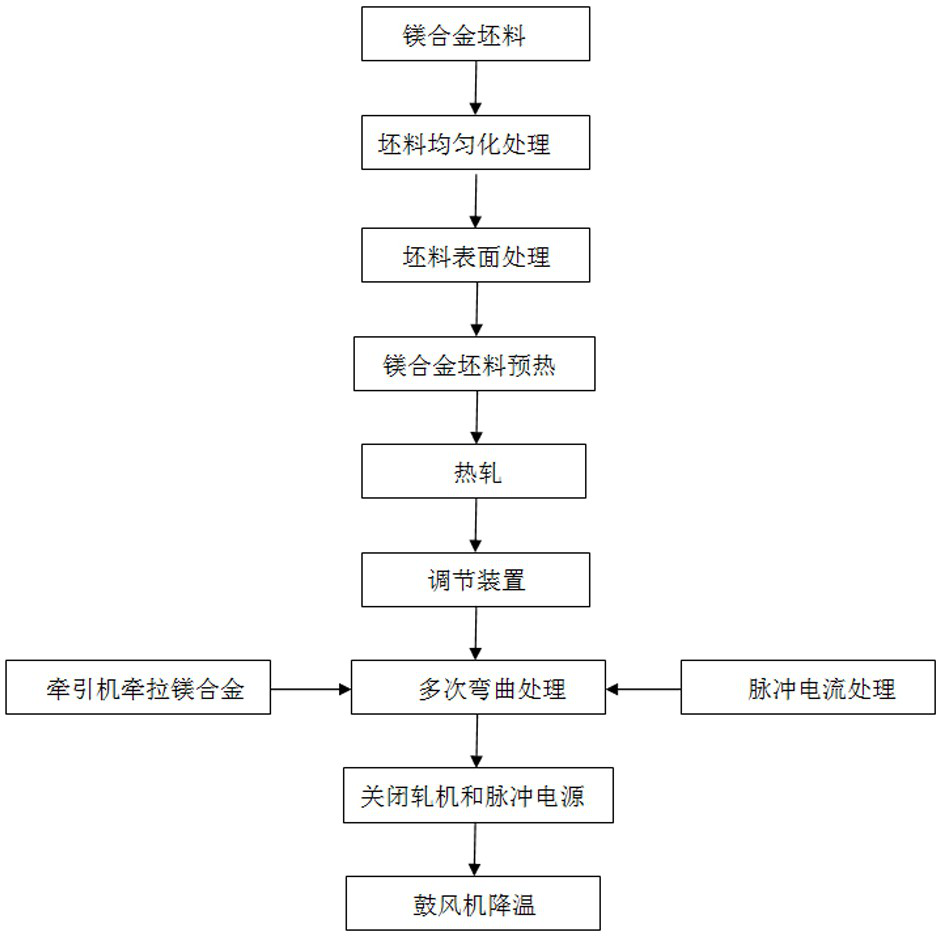

[0030] Processing a magnesium alloy billet whose size is 1000mm×50mm×0.5mm includes the following steps:

[0031] (1) Homogenization heat treatment of the magnesium alloy billet: put the magnesium alloy billet 1 into a heat treatment furnace, keep it at 450°C for 12h, then take it out and put it into pure water at 25°C for water cooling to room temperature.

[0032] (2) Surface treatment of the magnesium alloy billet: use sandpaper to remove the scale on the surface of the magnesium alloy billet 1, then clean it with an ultrasonic cleaner and anhydrous ethanol, and dry it with a hair dryer to prevent impurities on the surface of the magnesium alloy billet 1.

[0033] (3) Magnesium alloy billet preheating: put the magnesium alloy billet obtained in step 2) into a vacuum muffle furnace, heat up to 300° C., and keep the temperature for 40 minutes, so that the interior of the magnesium alloy billet 1 is evenly heated.

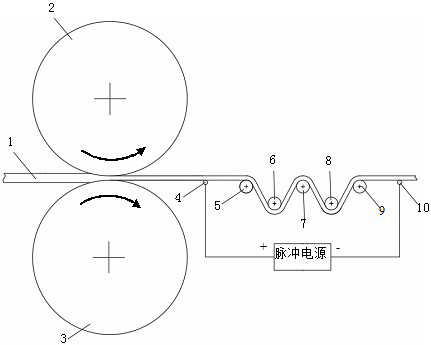

[0034] (4) Hot rolling: the uniformly heated magnesium alloy ...

Embodiment 2

[0041] Processing a magnesium alloy blank 1 with a size of 3000mm×40mm×1mm includes the following steps:

[0042] (1) Homogenization heat treatment of the magnesium alloy billet: put the magnesium alloy billet 1 into a heat treatment furnace, keep it warm at 400°C for 15h, then take it out and put it into pure water at 25°C for water cooling to room temperature.

[0043](2) Surface treatment of the magnesium alloy billet: use sandpaper to remove the scale on the surface of the magnesium alloy billet 1, then clean it with an ultrasonic cleaner and anhydrous ethanol, and dry it with a hair dryer to prevent impurities on the surface of the magnesium alloy billet 1.

[0044] (3) Magnesium alloy billet preheating: put the material obtained in step (2) into a vacuum muffle furnace, heat up to 400° C., and keep the temperature for 30 minutes, so that the interior of the magnesium alloy billet 1 is evenly heated.

[0045] (4) Hot rolling: quickly place the evenly heated magnesium allo...

Embodiment 3

[0052] Processing a magnesium alloy blank 1 with a size of 5000mm×20mm×2mm includes the following steps:

[0053] (1) Homogenization heat treatment of the magnesium alloy billet: put the magnesium alloy billet 1 into a heat treatment furnace, keep it at 380°C for 20 hours, then take it out and put it into pure water at 25°C for water cooling to room temperature.

[0054] (2) Surface treatment of the magnesium alloy billet: use sandpaper to remove the scale on the surface of the magnesium alloy billet 1, then clean it with an ultrasonic cleaner and anhydrous ethanol, and dry it with a hair dryer to prevent impurities on the surface of the magnesium alloy billet 1.

[0055] (3) Magnesium alloy billet preheating: put the material obtained in step (2) into a vacuum muffle furnace, heat up to 450° C., and keep the temperature for 20 minutes, so that the interior of the magnesium alloy billet 1 is evenly heated.

[0056] (4) Hot rolling: the uniformly heated magnesium alloy billet 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com