Dual-mode controller of electrical-mechanical converter

A converter and controller technology, applied in the direction of AC motor control, control system, electrical components, etc., can solve the PID controller response speed, overshoot and noise interference performance to maximize performance, poor linearity, inertia of moving parts major problems, to achieve the effect of shortening the total control time and retaining the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above objects, features and advantages of the present invention more comprehensible, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

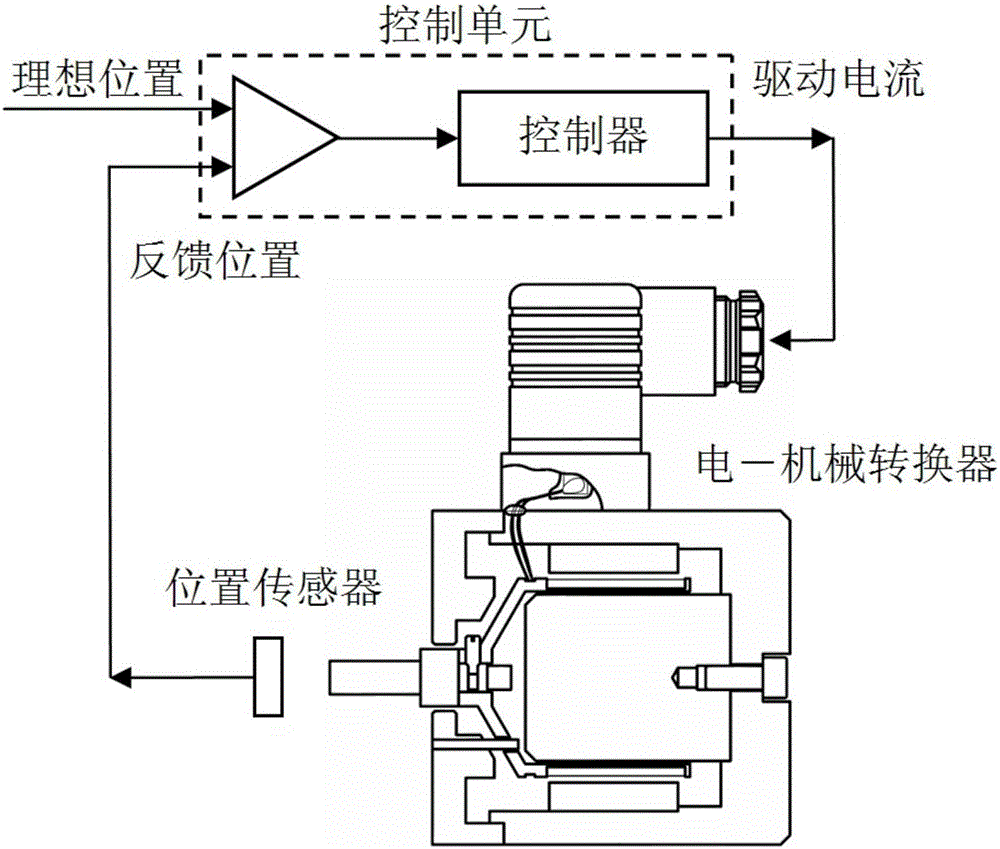

[0020] figure 1 It is the control schematic diagram of the electric-mechanical converter of the controlled object of the present invention. After the input signal is processed by the controller, it is loaded to the control coil. The current-carrying control coil and the bobbin are subjected to electromagnetic force in the constant magnetic field provided by the permanent magnet. The displacement is generated by the action, and the position error of the moving coil assembly is detected by the position sensor, which is compensated to the input signal to ensure that the moving coil assembly remains in the required correct position.

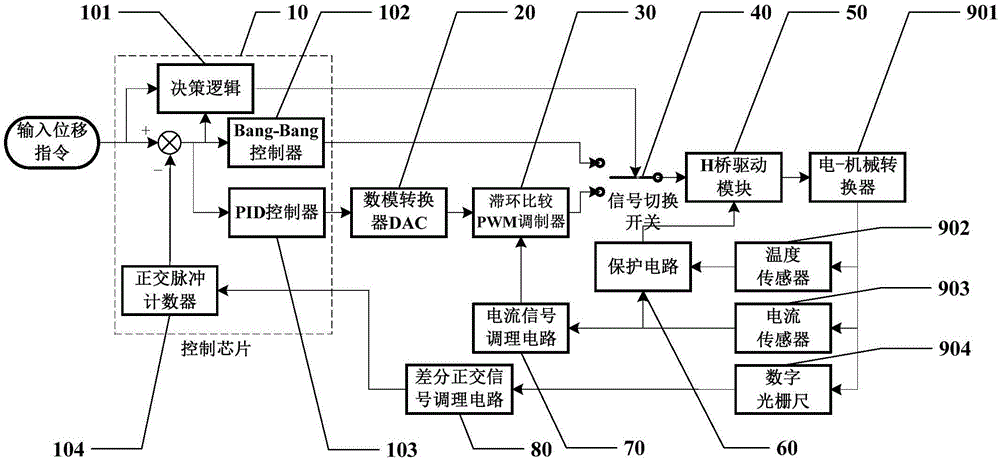

[0021] figure 2 It shows a dual-mode controller of an electro-mechanical convert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com