Solar cell fluorinated coating composition, fluorinated multilayer film, and solar cell comprising same

A technology of fluorine-based polymers and compositions, applied in coatings, circuits, photovoltaic power generation, etc., can solve the problems of yellowing solar cell module output, chemical resistance and weather resistance reduction, etc., and achieve improved adhesion , Improving chemical resistance, improving the effect of reflective properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

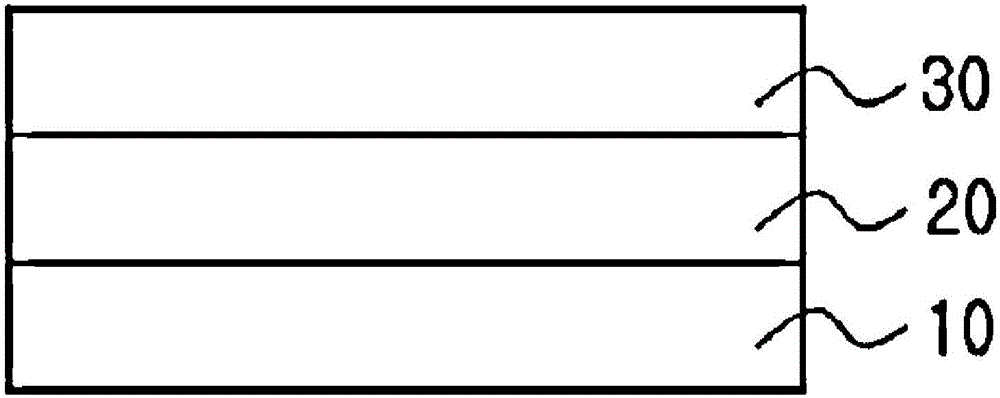

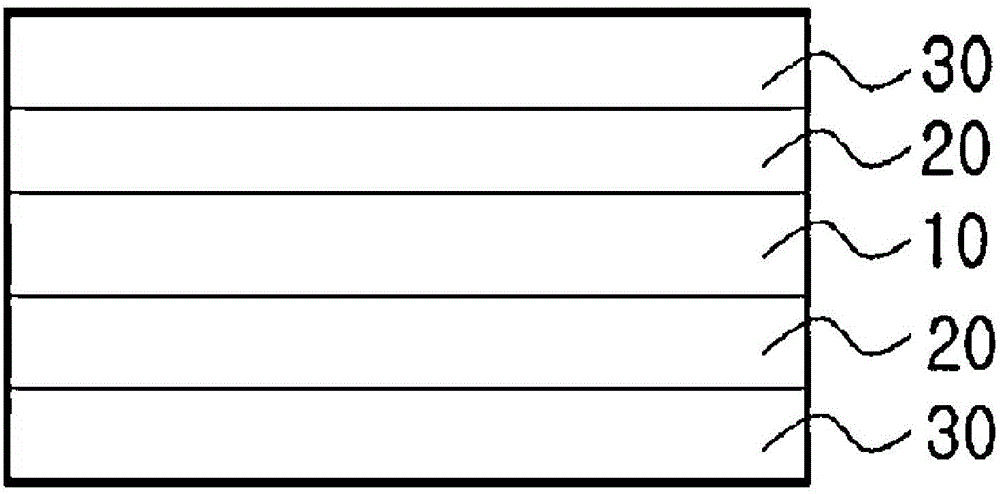

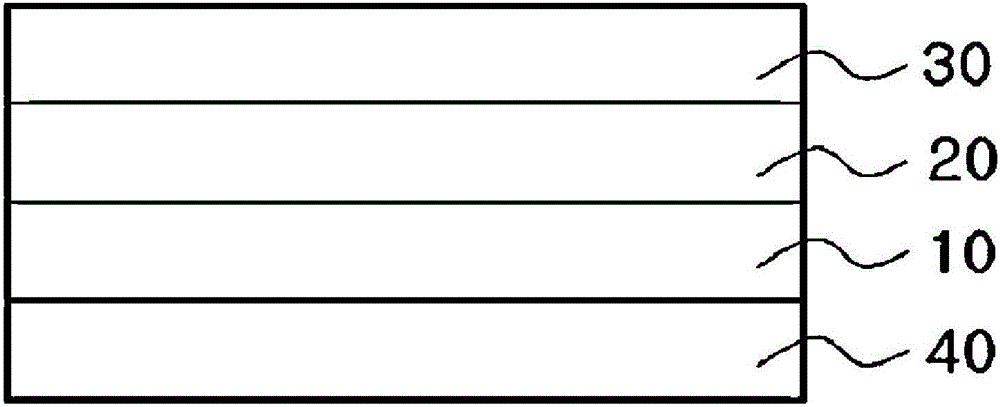

[0099] The preparation method of the fluorine-based multilayer film of an embodiment of the present invention may include:

[0100] A step of preparing a fluorine-based coating composition comprising a fluorine-based polymer, a polymer binder and an organic solvent;

[0101] A step of coating the above-mentioned fluorine-based coating composition on one or both sides of the substrate film, and curing to form a primer layer;

[0102] A step of preparing a second composition comprising a fluorine-based polymer, a white pigment, and an organic solvent; and

[0103] A step of coating the above-mentioned second composition on the top of the above-mentioned primer layer, and curing to form a weather-resistant coating.

[0104] In the step of preparing the above-mentioned fluorine-based coating composition and the second composition, it can be prepared by a usual mixing method. The above-mentioned mixing method is not particularly limited, as long as the physical and chemical prope...

preparation example 1

[0132] Preparation of Polymer Binder Using Alkoxysilyl Compounds(1)

[0133] As shown in the following Table 1, 2.85 g of methyl methacrylate (MMA, Samcheon Chemical, 99%), 0.15 g of 3-methacryloylpropyltrimethoxysilane were added to a 4-port reactor. (SZ-6030, Dow Corning (DowCorning) company), 0.02g of 2,2'-azobis (4-methoxy-2,4-dimethylvaleronitrile) (V-70, Wako Pure Chemicals (Wakopurechemicals) ) company), 12 g of isophorone (Sigma-Aldrich (Sigma-Aldrich) company), and polymerized at 60° C. for 6 hours to prepare a polymer binder (1).

preparation example 2-4

[0135] Preparation of Polymer Binder Using Alkoxysilyl Compounds(1)

[0136] As shown in the following Table 1, except that the contents of methyl methacrylate (MMA) and 3-methacryloylpropyltrimethoxysilane were changed, the preparation was carried out in the same manner as in Preparation Example 1, thereby preparing a polymer Adhesives (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com