Purifying process for extraction liquor of reconstituted tobacco

A technology for reconstituting tobacco leaves and purifying technology, which is applied in the fields of tobacco, tobacco preparation, and tobacco processing, can solve the problems of high equipment operation cost, difficulty in processing slag, and poor quality of extraction liquid purification, and achieves low operation cost and system operation. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

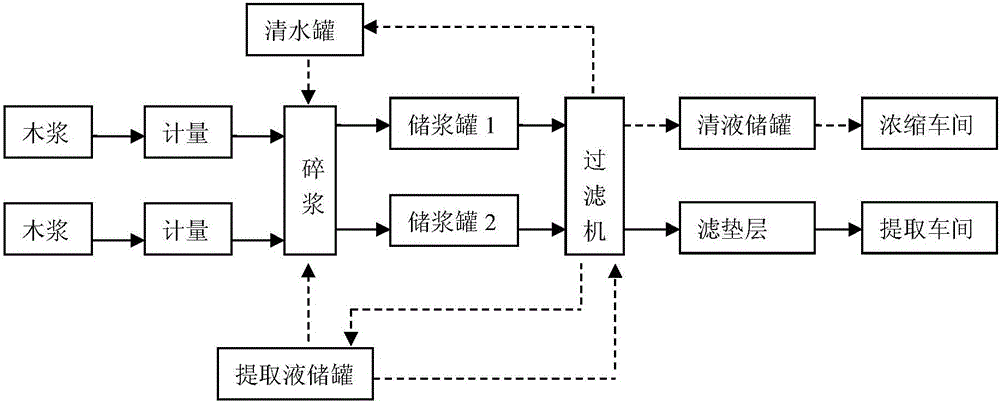

[0019] A process for purifying reconstituted tobacco leaf extract, the method steps are as follows:

[0020] (1) After the wood pulp board is measured and weighed, use a hydraulic pulper to obtain the clear water slurry after the wood pulp board is disentangled and processed with clear water, and send it into the first slurry storage tank to adjust the clear water slurry mass concentration to 0.3%-2%;

[0021] (2) After the wood pulp board is weighed, use a hydraulic pulper to decompose the wood pulp board with the tobacco raw material extract to obtain the extract slurry, and send it into the second pulp storage tank to adjust the extract slurry Material mass concentration to 0.3%-2%;

[0022] (3) The clear water slurry prepared in step (1) is delivered to the plate-type airtight blade filter with a slurry pump, and a filter cushion layer is formed on the surface of the filter screen of the filter, and the filtrate is sent back to the clear water tank. After the filter cush...

Embodiment 2

[0026] A process for purifying reconstituted tobacco leaf extract, the method steps are as follows:

[0027] (1) After measuring and weighing the wood pulp board, use a hydraulic pulper to decompose the wood pulp board with clean water to obtain a clean water slurry and send it into the first slurry storage tank, adjust the mass concentration of the clean water slurry to 0.3 %-2%;

[0028] (2) The clear water slurry prepared in step (1) is transported to the plate-type airtight blade filter with a slurry pump, and a filter cushion layer is formed on the surface of the filter screen of the filter, and the filtrate is sent back to the clear water tank. After the filter cushion layer has a thickness required by the process and meets the filtration accuracy requirements, stop the slurry supply and drain the remaining slurry in the filter and send it back to the first slurry storage tank;

[0029] (3) Transport the extract with a slurry pump to the plate-type airtight leaf filter ...

Embodiment 3

[0032] A process for purifying reconstituted tobacco leaf extract, the method steps are as follows:

[0033] (1) After weighing the wood pulp board, use a hydraulic pulper to decompose the wood pulp board with the tobacco raw material extraction liquid to obtain the extract liquid slurry, send it into the second pulp storage tank and adjust the extract liquid slurry Mass concentration to 0.3%-2%;

[0034] (2) The extract liquid slurry prepared in step (1) is delivered to the plate-type airtight blade filter with a slurry pump, and a filter cushion layer is formed on the surface of the filter screen of the filter, and the filtrate is returned to the extract liquid storage tank. After forming a filter cushion with a thickness required by the process on the net and meeting the requirements of filtration accuracy, stop the slurry supply and drain the remaining slurry in the filter and send it back to the second slurry storage tank;

[0035] (3) continue to carry out the filter pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com