The preparation method of silver powder

A silver powder and solution technology, applied in the field of silver powder preparation, can solve problems such as short reaction time, uniformity of industrialized products, dispersion deviation, etc., and achieve good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

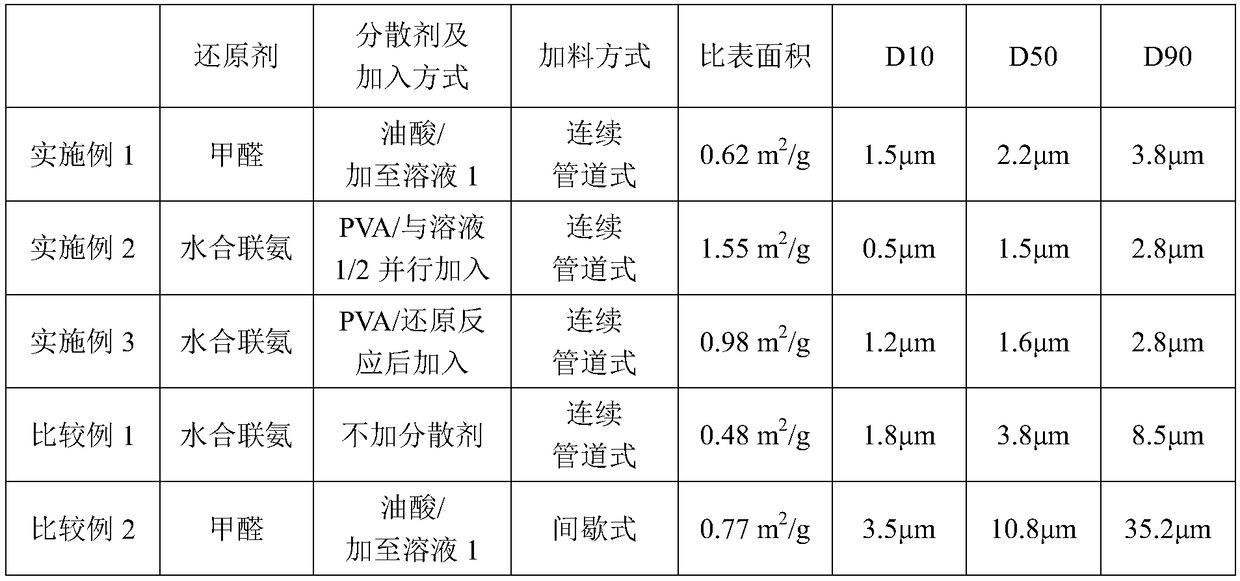

Examples

preparation example Construction

[0034] One aspect of the present invention provides a kind of preparation method of silver powder, comprising:

[0035] Respectively configure the water reaction system A containing silver ions, the reducing agent solution B, and the dispersant solution C;

[0036] Injecting A, B and C into a continuous pipeline reactor, mixing and reacting to deposit silver particles; and drying the silver particles, crushing and sieving.

[0037] Water reaction system A containing silver ions

[0038] As the aqueous reaction system containing silver ions, an aqueous solution or slurry containing silver nitrate, a silver salt complex, or a silver intermediate can be used. Silver salt complexes can be formed by adding ammonia water, ammonium salts, chelating compounds, and the like. Silver intermediates can be prepared by adding sodium hydroxide, sodium chloride, sodium carbonate, and the like. In the water reaction system of the present invention, the concentration of silver ions is prefe...

Embodiment approach 1

[0068] Embodiment 1. A preparation method of silver powder, comprising:

[0069] Respectively configure the water reaction system A containing silver ions, the reducing agent solution B, and the dispersant solution C;

[0070] A, B, and C are injected into a continuous pipe reactor, and the mixed reaction is carried out to deposit silver particles; and

[0071] The silver particles were dried, crushed and sieved.

Embodiment approach 2

[0072] Embodiment 2. The method of Embodiment 1, wherein the silver ion-containing water reaction system A comprises a silver-containing material and pure water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com