Water-based metal cleaning agent and preparation method thereof

A metal cleaning agent, water-based technology, used in the field of chemical products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

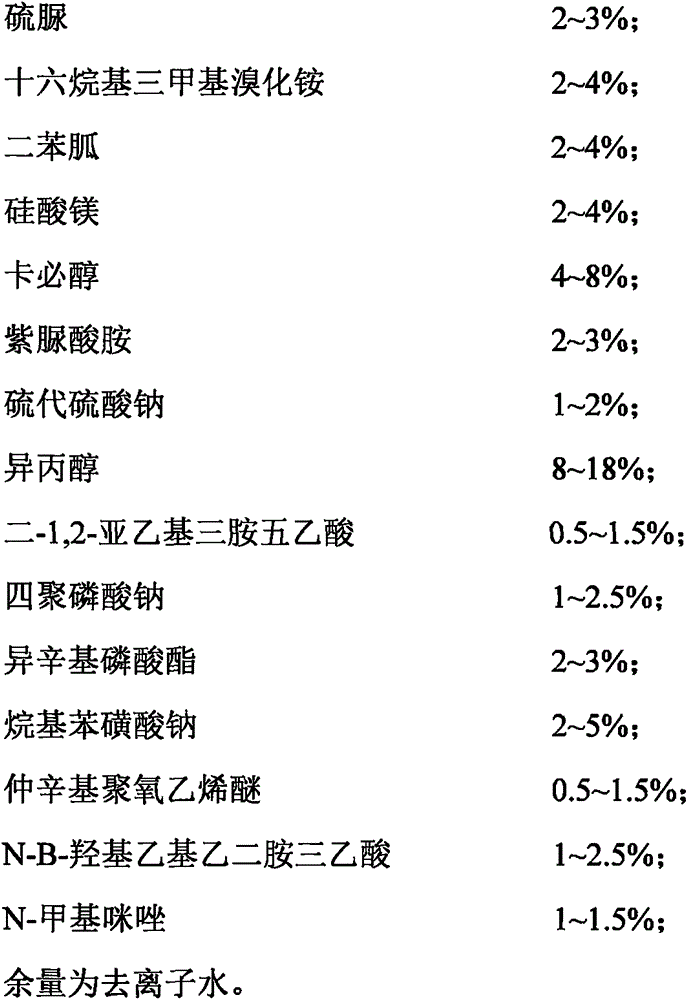

[0027] The first technical scheme of the present invention provides a kind of water-based metal cleaning agent, and its weight percent comprises following material:

[0028]

[0029]

[0030] The present invention also provides a kind of preparation method of above-mentioned water-based metal cleaning agent in order to solve the above-mentioned technical problem, wherein, comprises the following steps:

[0031] 1), at room temperature, mix corresponding parts by weight of carbitol, isopropanol and deionized water evenly to obtain a mixed solution, then mix magnesium silicate, sodium tetrapolyphosphate, N-B-hydroxyethyl ethylenediamine triacetic acid , Sodium thiosulfate was added to the above mixture until it was completely dissolved;

[0032] 2), adding di-1,2-ethylenetriaminepentaacetic acid, N-methylimidazole, cetyltrimethylammonium bromide, sodium alkylbenzenesulfonate, sec-octyl polyoxyethylene ether, Control the temperature at 60°C and keep stirring at this temper...

Embodiment 2

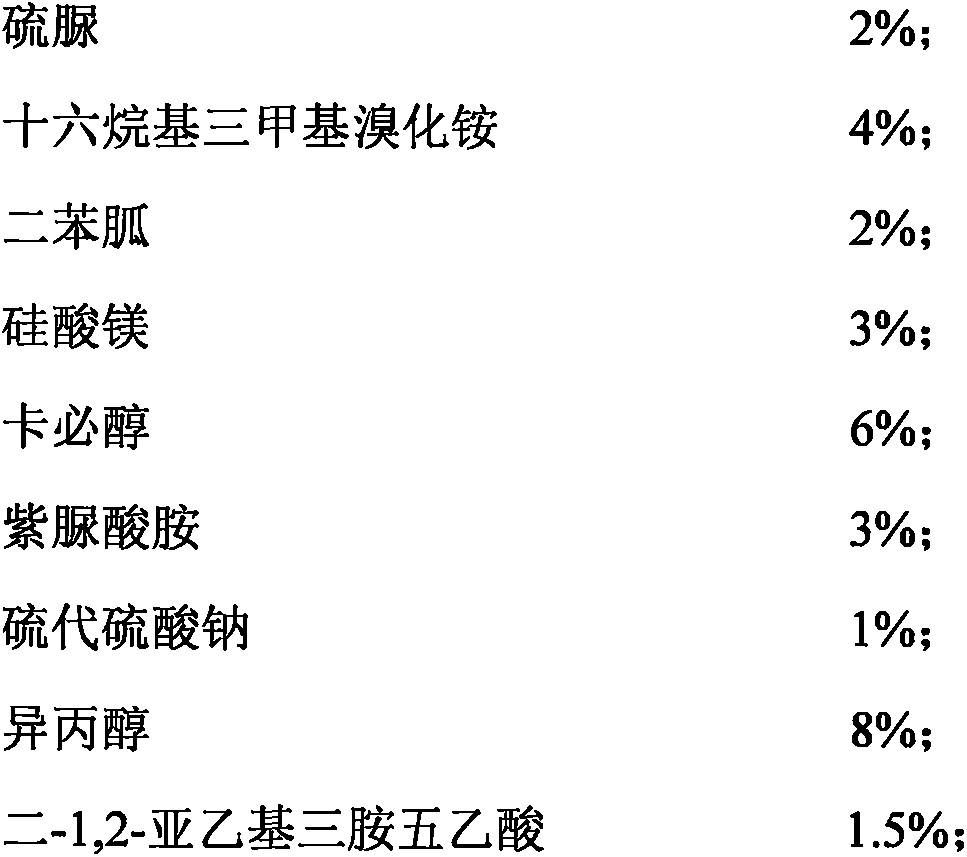

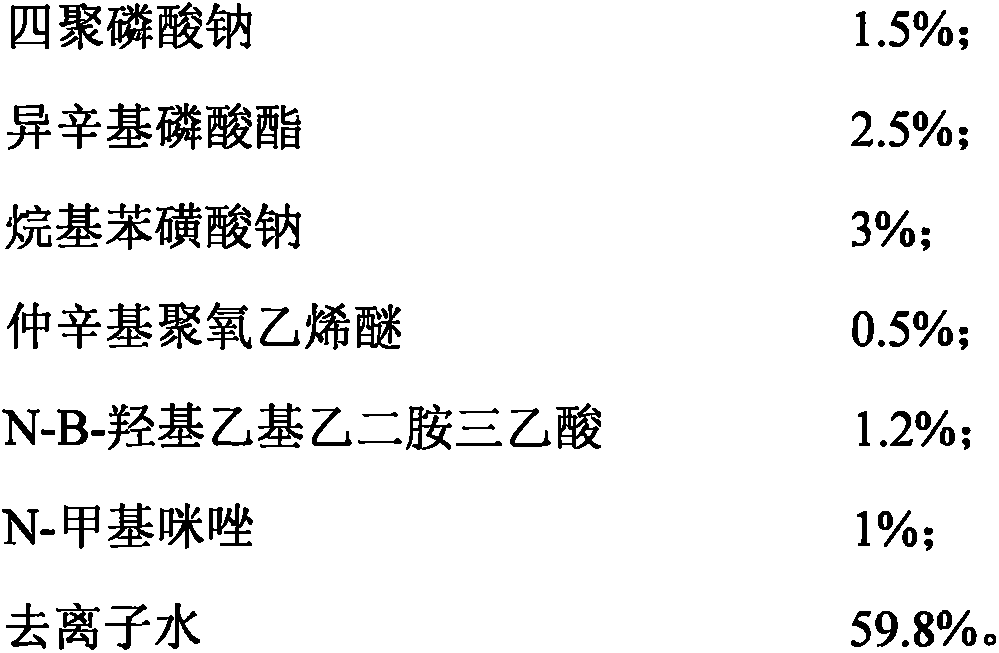

[0036] The second technical scheme of the present invention provides a kind of water-based metal cleaning agent, and its percentage by weight comprises following material:

[0037]

[0038]

[0039] The present invention also provides a kind of preparation method of above-mentioned water-based metal cleaning agent in order to solve the above-mentioned technical problem, wherein, comprises the following steps:

[0040] 1), at room temperature, mix corresponding parts by weight of carbitol, isopropanol and deionized water evenly to obtain a mixed solution, then mix magnesium silicate, sodium tetrapolyphosphate, N-B-hydroxyethyl ethylenediamine triacetic acid , Sodium thiosulfate was added to the above mixture until it was completely dissolved;

[0041] 2), adding di-1,2-ethylenetriaminepentaacetic acid, N-methylimidazole, cetyltrimethylammonium bromide, sodium alkylbenzenesulfonate, sec-octyl polyoxyethylene ether, Control the temperature at 65°C and keep stirring at this...

Embodiment 3

[0045] The third technical scheme of the present invention provides a kind of water-based metal cleaning agent, and its weight percentage comprises following material:

[0046]

[0047]

[0048] The present invention also provides a kind of preparation method of above-mentioned water-based metal cleaning agent in order to solve the above-mentioned technical problem, wherein, comprises the following steps:

[0049] 1), at room temperature, mix corresponding parts by weight of carbitol, isopropanol and deionized water evenly to obtain a mixed solution, then mix magnesium silicate, sodium tetrapolyphosphate, N-B-hydroxyethyl ethylenediamine triacetic acid , Sodium thiosulfate was added to the above mixture until it was completely dissolved;

[0050] 2), adding di-1,2-ethylenetriaminepentaacetic acid, N-methylimidazole, cetyltrimethylammonium bromide, sodium alkylbenzenesulfonate, sec-octyl polyoxyethylene ether, Control the temperature at 55°C and keep stirring at this tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com