Sound insulation and noise reduction method and device for MVR energy saving vaporization system

A technology of evaporation system and equipment, applied in the field of sound insulation and noise reduction and equipment of MVR energy-saving evaporation system, can solve the problems of large mechanical vibration amplitude of Roots compressor, far-reaching low-frequency noise, unable to start operation, etc. The effect of fitting response, reducing intensity, dampening resonance and fitting response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The sound insulation and noise reduction method and equipment of the MVR energy-saving evaporation system of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

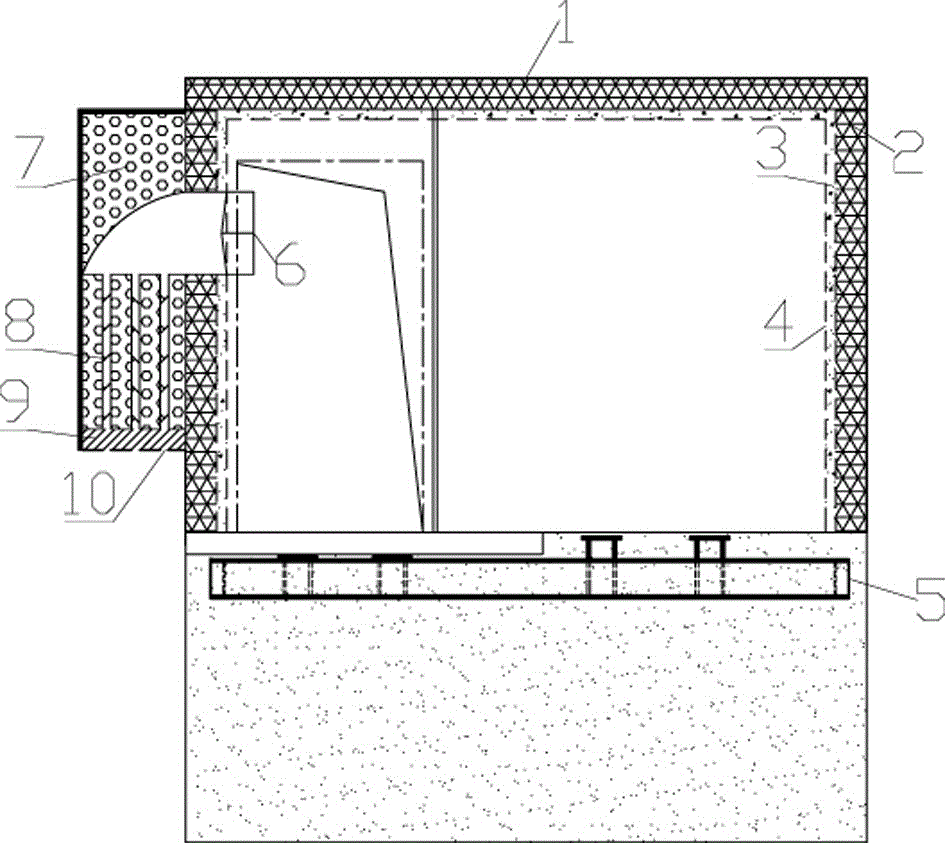

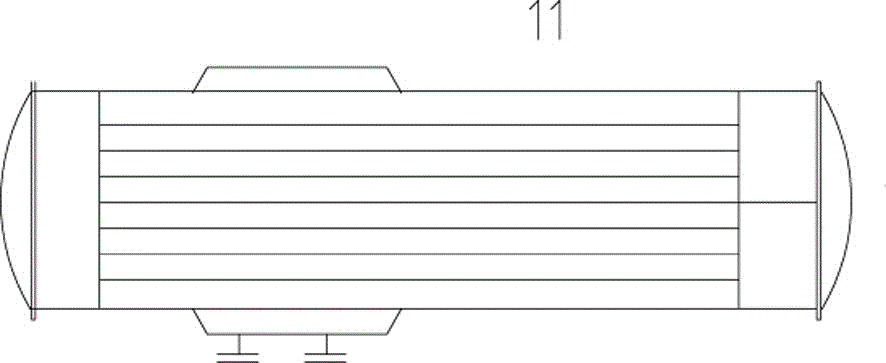

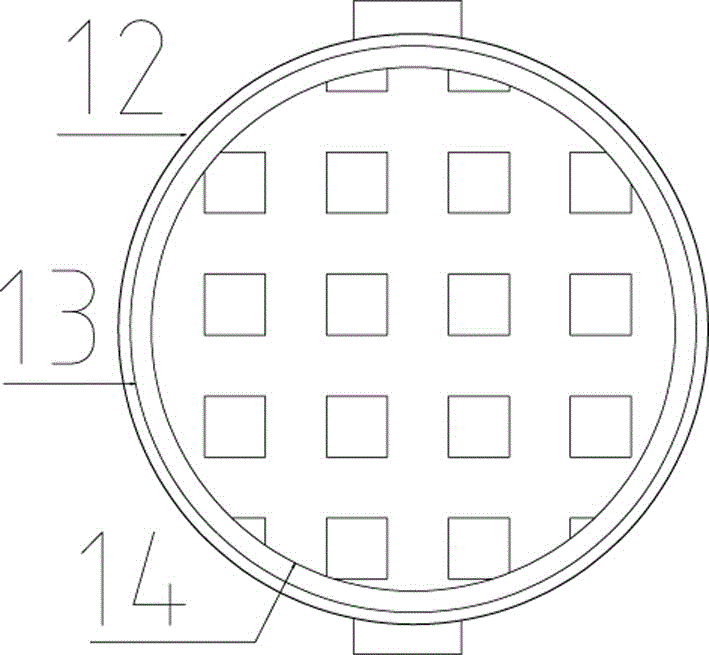

[0021] Figure 1-Figure 3 The specific implementation scheme of the sound insulation and noise reduction method and equipment of the MVR energy-saving evaporation system of the present invention shown is as follows:

[0022] (1) Sound insulation and noise reduction of Roots compressors: Sound insulation covers are used for Roots compressors to reduce noise. Absorbed by the sound-absorbing layer 3 of the sound-absorbing and insulating steel plate, and then secondly absorbed by the damping layer 2 of the composite sound-absorbing and insulating steel plate.

[0023] The sound-proof cover is composed of a 100mm thick composite sound-absorbing and insulating steel plate and a shock-absorbing base 5; the outermost layer of the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com