A woodworking lathe control system

A control system, woodworking lathe technology, applied in control systems, woodworking lathes, motor control, etc., can solve problems such as unfavorable use and safe operation of woodworking lathes, single current and voltage protection points, non-reversing woodworking lathes, etc., to improve the operation. Safety, guaranteeing work performance, and realizing the effect of stepless speed regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention provides a woodworking lathe control system, and the present invention will be further described below in combination with specific embodiments.

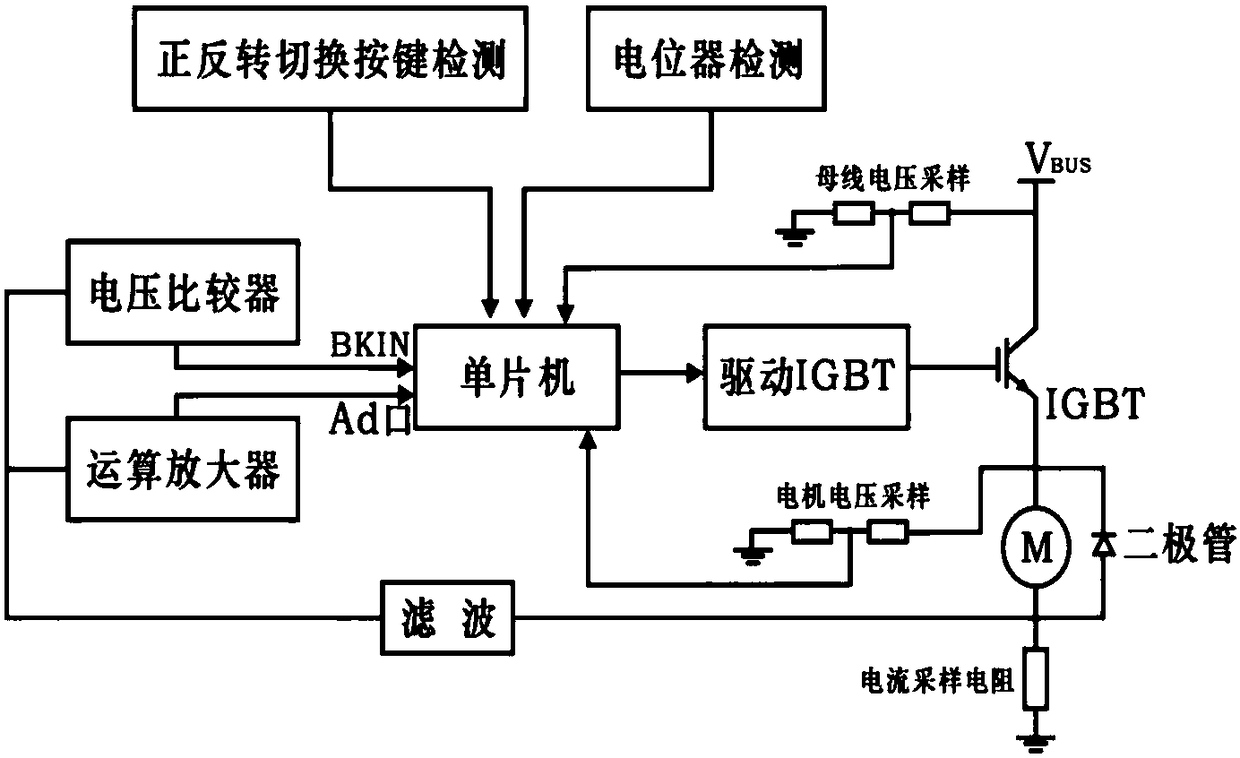

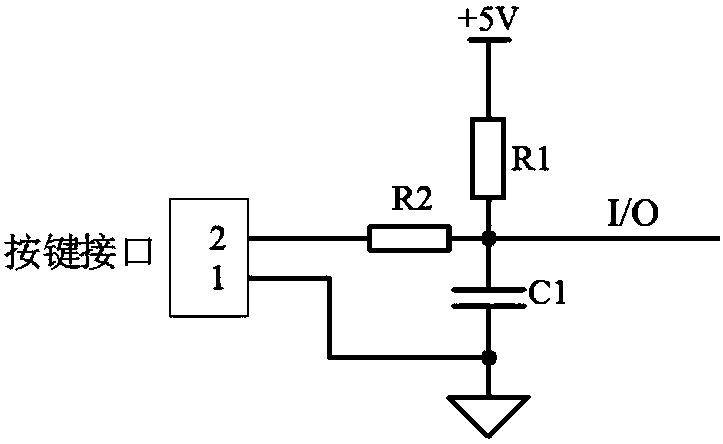

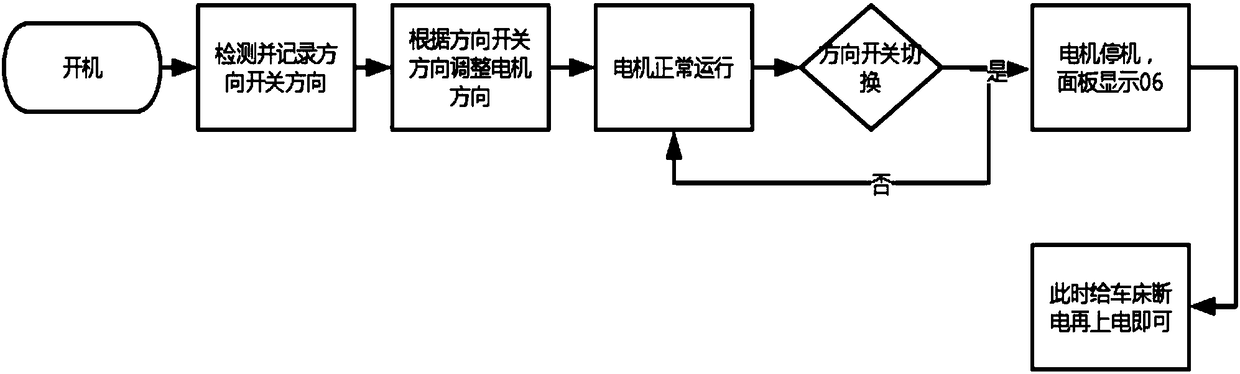

[0026] refer to figure 1 , which is a schematic structural diagram of the woodworking lathe control system in this embodiment, including a microcontroller, a forward and reverse button detection circuit, a motor and an IGBT drive circuit, and freewheeling diodes are connected to both ends of the motor, and the forward and reverse button detection circuit is connected to the microcontroller It also includes a bus voltage sampling module, a motor voltage sampling module and a current sampling module, which are used to detect the bus voltage, motor voltage and motor current respectively, and transmit the detected values to the microcontroller, and the microcontroller drives the circuit through the IGBT To control the action of the motor, the microcontroller in this embodiment uses a STM8S series single-ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com